ASTM A249 STAINLESS STEEL TUBES

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

ASTM A249 STAINLESS STEEL TUBES PRODUCTION RANGE AND SPECIFICATIONS

Type: Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes

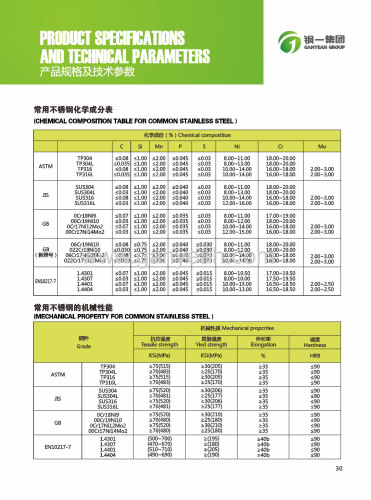

Grades: TP304, TP304L, TP304H, TP321H, TP321, TP316, TP316L, TP316Ti, TP310S, TP347, TP347H

Size: 1/8" NB to 80" NB, 1/4" OD to 80" OD sizes stainless steel seamless tubes also available

Length: Up to 6 meters, custom cut lengths

Thickness: 1mm to 13mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10

Finish: No.1 Pickled Finish, No.4 finish, BA Finish, Electropolished Pipes

Delivery Condition: Hot Finish, Cold Finish, Bright Annealed, Polished, Annealed and Pickled, Passivated, Stress Relived

Products: ASTM A249 TP304 Stainless Steel Tubes, ASTM A249 TP316L Stainless Steel Welded Tubes, SS 304 A249 Tubes, SS304L A249 Tubes, SS 316 A249 Tubes, SS316L A249 Tubes, SS310S A249 Tubes, SS 317L A249 Tubes, 446 A249 Tubes

ASTM A249 STAINLESS STEEL TUBES Some of the quality tests carried out by us includes:

| Corrosion Test | Conducted only when specially requested by the client |

| Chemical Analysis | Test done as per required quality standards |

| Destructive / Mechanical Testing | Tensile | Hardness | Flattening | Flare | Flange |

| Reverse-bend and Re. flat tests | Carried out in full compliance with relevant standards & ASTM A-450 and A-530 norms, which ensures trouble-free expansion, welding & use at customers end |

| Eddy Current Testing | Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System |

| Hydrostatic Testing | 100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s . |

| Air Under Pressure Test | To check any evidence of air leakage |

| Visual Inspection | After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections |

ASTM A249 STAINLESS STEEL TUBES Supplementary Testing : Apart from the above mentioned tests, we also carry out on the manufactured products supplementary testing. The tests conducted under this include:

|

|

|