SUS304 Stainless Steel Chemical Composition Tubing

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

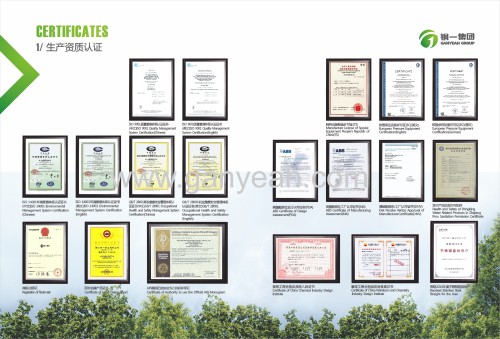

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

SUS304 Stainless Steel Chemical Composition Tubing

How to manufacture tubes and pipes

Tube manufacturing starts in the steel mill where either slabs or billets are cast. Production of seamless tubes starts from billets. Large diameter and heavy-walled pipes are made from hot-rolled plate, while strip welded tubes are mainly produced from cold-rolled or hot-rolled slit pre-material.

Manufacturing SUS304 Stainless Steel Chemical Composition Tubing

Depending on the outer dimension, wall thickness and final application, there are different ways of manufacturing welded tubes and pipes. Strip welded tubes are typically made in accordance with the production route shown in Figure 1. The material is decoiled, preferably into a strip accumulator which then enables continuous SUS304 Stainless Steel Chemical Composition Tubing production.

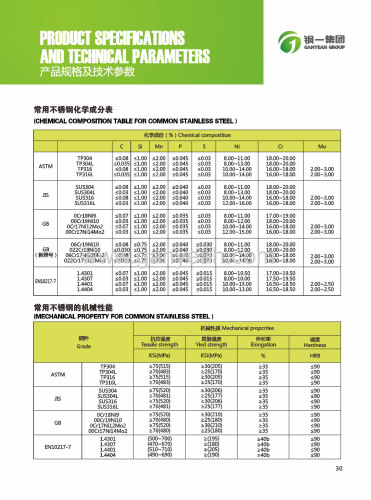

| MATERIAL CHEMICAL COMPOSITION (%) | |||||||||

| GRADE | C | Mn | P | S | Si | Ni | Cr | Mo | Ti |

| (Max.) | (Max.) | (Max.) | (Max.) | (Max.) | |||||

| 304 | 0.08 | 2.00 | 0.04 | 0.03 | 0.75 | 8.00-11.00 | 18.00-20.00 | - | - |

| 304L | 0.035 | 2.00 | 0.04 | 0.03 | 0.75 | 8.00-13.00 | 18.00-20.00 | - | - |

| 316 | 0.08 | 2.00 | 0.04 | 0.03 | 0.75 | 11.00-14.00 | 16.00-18.00 | 2.00-3.00 | - |

| 316L | 0.035 | 2.00 | 0.04 | 0.03 | 0.75 | 10.00-15.00 | 16.00-18.00 | 2.00-3.00 | - |

| 321 | 0.08 | 2.00 | 0.04 | 0.03 | 0.75 | 9.00-13.00 | 17.00-20.00 | - | >5c |

| 316Ti | 0.08 | 2.00 | 0.04 | 0.03 | 1.00 | 11.00-14.00 | 16.5-18.5 | 2.25-3.0 | >5c |