S32750/1.4410 Duplex Steel Tube

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

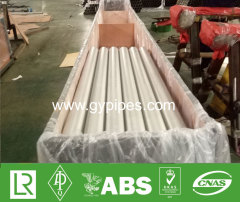

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

S32750/1.4410 Duplex Steel Tube has enhanced pitting and crevice corrosion resistance compared with the ordinaryaustenitic or duplex types. This is due to the further additions of chromium, molybdenum, and nitrogen to these grades. UNS S32760, F55, 1.4501 combines high strength and good ductility with outstanding corrosion resistance. With UNS S32760, F55, 1.4501 having these attribute it is used in a wide range of marine, oil and gas environments. UNS S32760, F55, 1.4501 is the most common super duplex grade.

S32750/1.4410 Duplex Steel Tube has excellent corrosion resistance to a wide variety of media, with outstanding resistance to pitting and crevice corrosion in seawater and other chloride containing environments, with Critical Pitting Temperature exceeding 50°C.UNS S32760, F55, 1.4501 Super Duplex has enhanced pitting and crevice corrosion resistance compared with the ordinary austenitic or duplex types. This is due to the further additions of chromium, molybdenum, and nitrogen to these grades. UNS S32760, 1.4501 combines high strength and good ductility with outstanding corrosion resistance.

Providing higher strength than both austenitic and 22% Cr S32750/1.4410 Duplex Steel Tube is suited to a variety of applications in industries such as Chemical Processing, Oil & Gas, and Marine environments. Super Duplex Alloy UNS S32760 (F55 / 1.4501) has excellent corrosion resistance to a wide variety of media, with outstanding resistance to pitting and crevice corrosion in seawater and other chloride containing environments, with Critical Pitting Temperature exceeding 50°C.

| Chemical Composition | ||||||||||

| C. | Cr. | Cu. | Mn. | Mo. | N. | Ni. | P. | S. | Si. | W. |

| 0.03% | 24.00- | 0.50- | 1.00% | 3.00- | 0.20- | 6.00- | 0.035% | 0.015% | 1.00% | 0.50- |

| max | 26.00% | 1.00% | max | 4.00% | 0.30% | 8.00% | max | max | max | 1.00% |

Minimum Mechanical Properties at Room Temperature

(EN10088-3 1.4501 UNS S32760 F55 160mm dia max - solution treated)

| Tensile (UTS) | 730 - 930 N/mm² | |

| 0.2% Proof Stress | 530 N/mm² Min | |

| Elongation | 25% min | |

| Hardness | 290HB Max | |

| Impact | 100J |

Super Duplex Stainless Steel Specifications EN10088-3 UNS S32760 F55 1.4501 Grade X2CrNiMoCuWN25-7-4 ASTM A182 F55 NACE MR01-75 ISI 15156ASTM A276 A314 SAE J405 Norsok MDS D51 D55 D57 D58

Super Duplex stainless steel – with a microstructure of 50:50 austenite and ferrite, the steel has improved strength over ferritic and austenitic steel grades. With a higher than average Molybdenum and Chromium content, the material has greater heat and corrosion resistant qualities.

With reduced production costs when compared with equivalent austenitic and ferritic grades and with greater yield and tensile strength, SuperDuplex is a cost effective solution for the consumer. It is conceivable that material thicknesses for a project may be reduced if SuperDuplex is used, thus reducing cost without compromising quality.

Benefits of UNS S32760 Super Duplex Stainless Steel

Increased tensile & yield strength

Good ductility and toughness

SCC resistance

Corrosion resistance is better than Duplex

Cost effective

- Applications

UNS S32760 is used in the oil and gas industry, on offshore platforms, in heat exchanger, chemical processing equipment, pressure vessels and boilers.

Oil and gas industry equipment,

Offshore platforms, heat exchangers, process and service water systems, fire-fighting systems, injection and ballast water systems,

Chemical process industries, heat exchanger, vessels, and piping,

Desalination plants, high pressure RO-plants and seawater piping,

Mechanical and structural components, high strength, corrosion-resistant parts,

Power industry FGD systems, utility and industrial scrubber systems, absorber towers, ducting, and piping.

Super Duplex Corrosion Resistance

The high chromium and molybdenum content of Super Duplex makes it extremely resistant to uniform corrosion by organic acids like formic and acetic acid. Super Duplex also provides excellent resistance to inorganic acids, especially those containing chlorides.