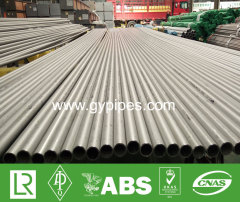

Duplex Steel Pipe Welding

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

Product Name: Super Duplex Stainless Steel Pipe A790/A789 S32750, S32760, UNS S31803, UNS 32160, UNS S32205

Standard: ASTM A789,ASTM A790, ASTM A213, A269, A312, A511, A789, A790, A376, EN 10216-5, EN 10297,DIN 17456, DIN 17458,JISG3459, JIS GS3463, GS3467, JIS G3448, GOST 9940, GOST 9941,GB/T 21833

Material: S32750 SAF2507 F53 1.4410 X2CrNiMoN25-7-4 , S32760 1.4501 F55 X2CrNiMoCuWN25-7-4 , UNS S31803, UNS 32160, UNS S32205

Nominal Dia: 1/2 "to 32" NB for seam pipe

Schedules: 5S, 10S, 40S, 80S, 10, 20, 30...120, 140, 160, XXS

All dimensions are in accordance with ANSI B36.19 and ANSI B36.10

Size Range for tubing: OD:1/4" (6.25mm) to 8" (203mm), WT: 0.02" (0.5mm) to 0.5"(12mm)

Length:5.8m, 6m, 11.8m, 12m, 30m(Max) or as your requirement

Process: Cold drawn, Cold rolled, Precision Rolled for Seamless Pipe or Tube

Finish: Annealed & pickled, bright annealing, polished

Ends: Beveled or plain end, square cut, burr free ,Plastic Cap at Both end

Chemical Composition:

| C | Mn | P | S | Si | Cr | Ni | Mo | N | Cu | |

S32750(SAF2507) 00Cr25Ni7Mo4N | 0.03max | 1.2max | 0.035max | 0.02max | 0.8max | 24.0~26.0 | 6.0~8.0 | 3.0~5.0 | 0.24~0.32 | 0.05max |

| S31803(SAF2205)00Cr22Ni5Mo3N | 0.03max | 2.0max | 0.03max | 0.02max | 1.0max | 21.0~23.0 | 4.5~6.5 | 2.5~3.5 | 0.08~0.20 | / |

S31500(3RE60) 00Cr18Ni5Mo3Si2 | 0.03max | 1.2~2.0 | 0.03max | 0.03max | 1.4~2.0 | 18.0~19.0 | 4.25~5.25 | 2.5~3.0 | 0.05~0.10 | / |

Inspection and Test:

| 1.100% PMI,Spectro Chemical Aanlysis Test for Raw Material |

| 2.100% Dimension & Visual Examination |

| 3. Mechanical Properties Test Include Tension Test,Flaring Test (For Seamless tube/pipe)/ Flange Test (For Welded Pipe & Tube), Hardness Test ,Reversed Flattening Test |

| 4.100% Hydrostatic Test or 100% NON-DESTRUCTIVE Test (ET or UT) |

| 5.Radiographic Test for Welded Pipe (shall be accordance with specification,or shall be as agreed upon between the purchaser and vendor) |

| 6.Straightness Test (optional) |

| 7.Roughness Test (optional) |

| 8.Intergranular Corrosion Test(optional) |

| 9.Impact Test (optional) |

| 10.Grain Size Determinations (optional) |