Welded Standard Steel Pipe

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

"GANYEAH GROUP" is Manufacturer and Supplier of S.S. Pipes & Tubes. We at Inox are committed to consistently provide high quality & timely products, through optimum utilization of available resources and technical expertise. We are committed to continuously improve effectiveness of our Quality Management System to enhance quality of our product and ensure a long lasting growing relationship with our customers.

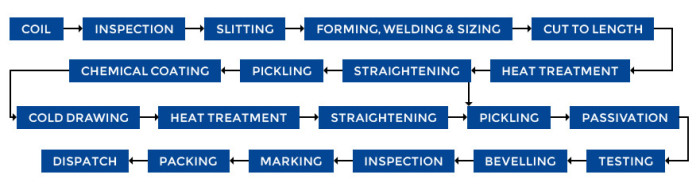

MANUFACTURING PROCESS

Raw Materials :

Raw Material for manufacturing of Pipes & Tubes/Welded Standard Steel Pipe are sourced only from approved vendors. The quality requirements for raw materials are governed by technical parameters by quality assurance department and relevant technical specifications.

Welded Standard Steel Pipe

Inox Pipes & Fittings Industries have a facilities of TIG welded tube with bead rolling as per the clients requirements.

Stainless steel tubes find application into critical and corrosive environment as such the qualities of tubes are maintained with precise tolerance as per the required national and international standards.

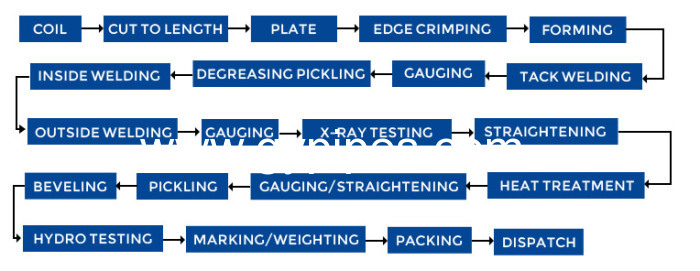

LARGE DIAMETER WELDED PIPES

Stainless steel pipes (Welded)/Welded Standard Steel Pipe is formed on 1000 M.T. hydraulic press in length up to 6.0 to 7.0 meters. This section produces S.S. pipes (Welded) as per ASTM A 358 by TIG welding and filler materials is used. The large diameter pipes is then sized & straightened, using 150 M.T. capacity hydraulic press to meet dimensional requirements of the applicable specifications. Tests are done according to specifications & additional quality checks by either Xray or Hydrostatic method.

U TUBES