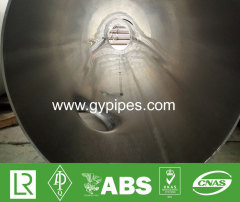

Tig Welding Stainless Pipe

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

The Process of Tig Welding Stainless Pipe

The energy required for melting the stainless steel is delivered in the form of an electric arc. This electric arc is struck and maintained between the tungsten or tungsten alloy electrode and the stainless steel work piece. This process is completed under an inert or slightly reducing atmosphere.

Welds produced on stainless steels are always done in the Direct Current Electrode Negative (DCEN) or Direct Current Straight Polarity (DCSP) mode.

The process involves the stainless steel work piece being struck by the electrons, thus enhancing penetration. The electrode itself undergoes very little wear.

In cases where filler metals are used, it is done so in the form of bare rods or, in automatic welding processes, coiled wire.

The flow of the inert gas used protects the arc zone from ambient air, which in turn enables the maintenance of a stable arc. Based on the materials being welded, an appropriate shielding gas will be selected.

The selection of the shielding gas influences the following factors:

Shielding efficiency.

The stainless steel's resistance to corrosion.

The emission of gasses and fumes during the welding process.

The arc's ignition and stability.

The weld's geometry.

The resulting surface appearance (in terms of oxidation, spatters etc.).

The loss of alloying elements and the pickup of atmospheric gasses.

And in some cases, metal transfer.

The Advantages of Tig Welding Stainless Pipe

Using TIG Welding on stainless steel offers the following advantages to manufacturers:

A very low electrode wear.

The creation of pore-free, sound welds.

TIG welding offers a concentrated heat source, which in turn leads to a narrow fusion zone.

It offers a precise control over penetration as weld as the weld's shape in all positions.

TIG welding has a very stable arc.

There is no spatter as no flux is needed in the welding process.

The residue of oxidation is eliminated, resulting in a simplified final cleaning process.