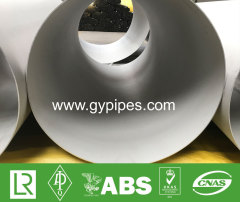

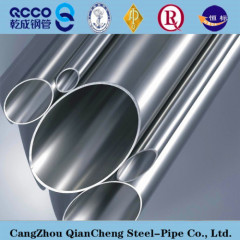

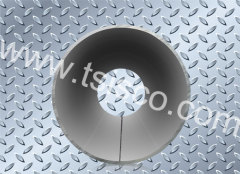

Welded Steel Stainless Steel Pipes

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

Welded Steel Stainless Steel Pipes

Welded Steel Stainless Steel Pipes is a materialistic stainless steel which is attractive, opposes consumption in mellow situations and has genuinely great flexibility. Stainless Steel 410 is utilized where scraped area and wear resistance is required, joined with reasonable imperviousness to general consumption and oxidation.

SPECIFICATIONS:

o ASTM/ASME: UNS S41000

o EURONORM: FeMi35Cr20Cu4Mo2

o DIN: 2.4660

FEATURES OF Welded Steel Stainless Steel Pipes

o Martensitic stainless steel with high mechanical properties.

o Ferromagnetic in the strengthened or solidified condition.

o Contains least measure of chromium to grant stainless steel properties.

o Opposes oxidation and scaling up to 1200°F.

o Opposes scraped spot and wear well than most 300 arrangement stainless steels.

APPLICATIONS OF Welded Steel Stainless Steel Pipes:

Applications obliging moderate erosion resistance and high mechanical properties are perfect for Alloy 410. Illustrations of uses that regularly utilized Alloy 410 include:

o Cutlery

o Steam and gas turbine sharpened pieces of steels

o Kitchen utensils

o Screws, nuts, screws

o Pump and valve parts and shafts

o Mine stepping stool floor coverings

o Dental and surgical instruments

o Spouts

o Solidified steel balls and seats for oil well pumps

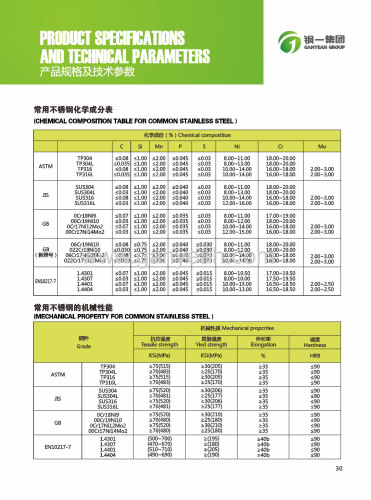

CHEMICAL COMPOSITION OF STAINLESS STEEL 410:

C | Mn | Si | P | S | Cr | Ni | |

410 | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 11.5 | 0.50 max |

MECHANICAL PROPERTIES OF STAINLESS STEEL 410:

Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

410 | 65 (450) | 30 (205) | 20 | 217 | 96 |

MECHANICAL PROPERTIES OF HEAT TREATED 410:

Heat Treatment | T410 (0.14%C) Hardened 1800°F (982°C) | ||

Rockwell Hardness | 0.2% YS, Ksi (MPa) | UTS, Ksi (MPa) | |

Annealed* | 81 HRB | 45.4 (313) | 80.4 (554) |

Hardened & Tempered 400°F (204°C) | 43 HRC | 156.1 (1076) | 202.9 (1399) |

Hardened & Tempered 550°F (288°C) | 40 HRC | 148.3 (1022) | 187.0 (1289) |

Hardened & Tempered 600°F (316°C) | 40 HRC | 148.8 (1026) | 186.1 (1283) |

Hardened & Tempered 800°F (427°C) | 41 HRC | 132.9 (916) | 188.5 (1300) |

Hardened & Tempered 900°F (482°C) | 41 HRC | 122.6 (845) | 154.3 (1063) |

Hardened & Tempered 1000°F (538°C) | 35 HRC | 127.9 (882) | 154.3 (1063) |

Hardened & Tempered 1200°F (649°C) | 98 HRB | 85.5 (589) | 111.2 (767) |

PHYSICAL PROPERTIES OF STAINLESS STEEL 410:

Density | Thermal Conductivity | Electrical | Modulus of | Coefficient of | Specific Heat | Melting |

at 68°F: 0.276 | 14.4 at 212°F | 56 at 68°F | 29 | 5.90 at 68 – 392°F | 0.11 at 68°F to 212°F | 2700 to 2790 |

6.5 at 68 – 1112°F |