Grades Of Stainless Steel 304 316 Pipe

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

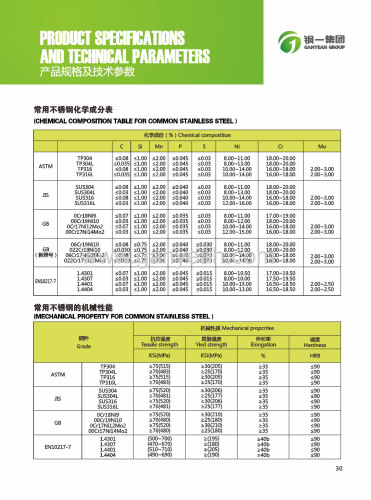

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

Grades Of Stainless Steel 304 316 Pipe

The manufacturing, distribution and sales of welded stainless steel process Grades Of Stainless Steel 304 316 Pipe and heat exchanger tubes, require that the customers' needs regarding the safe conveyance of corrosive, flammable and toxic fluids and gases must be fulfilled. GANYEAH offers from our extensive stock program articles for all types of applications within the process industries.

Manufacturing units with in-line equipment of the highest technology in combination with a quality system approved according to EN ISO 9001:2008 form the basis for our high quality. All our European plants are approved to the European Pressure Equipment Directive PED 97/23/EC and are certified by TÜV to AD 2000-Merkblatt W0, which fulfils the highest quality requirements from customers. Our welding operators and processes for pipe production are also approved to release materials certified to ASTM/ASME.

Our stock program together with world-wide supply capabilities secures a high availability and fast delivery service for any application. If thin or thick, big or small, long or short, corrosion-, acid- or heat resistant, in different applications, OSTP always has the right solution for your needs

ALLOWABLE WORKING PRESSURES FOR A-312 Grades Of Stainless Steel 304 316 Pipe

TYPE 304L

Schedules 40S, 80S

TEMPERATURE ºF. | − 425 to 300 |

400 |

500 |

600 |

650 |

700 |

750 |

800 |

850 |

900 |

950 |

1000 |

1050 |

1100 |

1150 |

1200 |

1250 |

1300 |

1350 |

1400 |

1450 |

1500 | ||

MAX. STRESS | 16700 | 15800 | 14800 | 14000 | 13700 | 13500 | 13300 | 13000 | 12800 | 11900 | 9900 | 7800 | 6300 | 5100 | 4000 | 3200 | 2600 | 2100 | 1700 | 1100 | 1000 | 900 | ||

NOM. PIPE SIZE | SCH. NO. | NOM. WALL. |

ALLOWABLE WORKING PRESSURES PSIG | |||||||||||||||||||||

½ | 40S 80S | .109 .147 | 3034 4092 | 2870 3871 | 2689 3626 | 2543 3430 | 2489 3357 | 2453 3308 | 2146 3259 | 2362 3185 | 2325 3136 | 2162 2916 | 1799 2426 | 1417 1911 | 1145 1544 | 927 1250 | 727 980 | 581 784 | 472 637 | 382 515 | 309 417 | 200 270 | 182 245 | 164 221 |

¾ | 40S 80S | .113 .154 | 2516 3429 | 2381 3244 | 2230 3039 | 2109 2875 | 2064 2813 | 2034 2772 | 2004 2731 | 1959 2669 | 1929 2628 | 1793 2443 | 1492 2033 | 1175 1602 | 949 1294 | 768 1047 | 603 821 | 482 657 | 392 534 | 316 431 | 256 349 | 166 226 | 151 205 | 136 185 |

1 | 40S 80S | .133 .179 | 2365 3183 | 2237 3011 | 2096 2820 | 1962 2668 | 1940 2611 | 1912 2573 | 1863 2535 | 1841 2477 | 1812 2439 | 1685 2268 | 1402 1887 | 1104 1486 | 892 1201 | 722 972 | 566 762 | 453 610 | 368 495 | 297 400 | 241 324 | 156 210 | 142 191 | 127 172 |

1¼ | 40S 80S | .140 .191 | 1972 2690 | 1866 2545 | 1747 2384 | 1653 2255 | 1618 2207 | 1594 2175 | 1570 2142 | 1535 2094 | 1511 2062 | 1405 1917 | 1169 1595 | 921 1256 | 744 1015 | 602 822 | 472 644 | 376 515 | 307 419 | 248 338 | 201 274 | 130 177 | 118 161 | 106 145 |

1½ | 40S 80S | .145 .200 | 1784 2461 | 1688 2328 | 1561 2181 | 1496 2063 | 1464 2019 | 1442 1989 | 1421 1960 | 1389 1916 | 1368 1886 | 1271 1754 | 1058 1459 | 833 1149 | 673 928 | 545 752 | 427 589 | 342 472 | 278 383 | 224 309 | 182 251 | 118 162 | 107 147 | 96 133 |

2 | 40S 80S | .154 .218 | 1516 2146 | 1434 2030 | 1344 1902 | 1271 1799 | 1244 1761 | 1226 1735 | 1207 1709 | 1180 1671 | 1162 1645 | 1080 1529 | 899 1272 | 708 1002 | 572 810 | 463 655 | 363 514 | 290 411 | 236 334 | 191 270 | 154 218 | 100 141 | 91 129 | 82 116 |

2½ | 40S 80S | .203 .276 | 1651 2244 | 1562 2124 | 1463 1989 | 1384 1882 | 1354 1841 | 1335 1814 | 1315 1788 | 1285 1747 | 1265 1720 | 1176 1599 | 979 1331 | 771 1048 | 623 847 | 504 685 | 395 538 | 316 430 | 257 349 | 208 282 | 168 228 | 109 148 | 99 134 | 89 121 |

3 | 40S 80S | .216 .300 | 1443 2004 | 1365 1896 | 1279 1776 | 1210 1680 | 1184 1644 | 1166 1620 | 1149 1596 | 1123 1560 | 1106 1536 | 1028 1428 | 855 1188 | 674 938 | 544 756 | 441 612 | 348 480 | 276 384 | 225 312 | 181 252 | 147 204 | 95 132 | 86 120 | 78 108 |

3½ | 40S 80S | .226 .318 | 1321 1859 | 1250 1759 | 1171 1647 | 1107 1558 | 1084 1525 | 1068 1503 | 1052 1460 | 1028 1447 | 1012 1425 | 941 1324 | 783 1102 | 617 868 | 498 701 | 403 568 | 316 445 | 253 356 | 206 289 | 166 234 | 134 169 | 87 122 | 79 111 | 71 100 |

4 | 40S 80S | .237 .337 | 1231 1751 | 1165 1657 | 1091 1552 | 1032 1468 | 1010 1436 | 995 1415 | 981 1394 | 959 1363 | 944 1342 | 877 1248 | 730 1038 | 575 818 | 465 661 | 376 535 | 295 419 | 236 336 | 192 273 | 155 220 | 125 178 | 81 115 | 74 105 | 66 94 |

5 | 40S 80S | .258 .375 | 1084 1576 | 1026 1491 | 961 1397 | 909 1321 | 890 1293 | 877 1274 | 864 1255 | 844 1227 | 831 1208 | 773 1123 | 643 934 | 506 738 | 409 595 | 331 481 | 260 377 | 208 302 | 169 245 | 136 198 | 110 160 | 71 104 | 65 94 | 58 85 |

6 | 40S 80S | .280 .432 | 988 1525 | 935 1442 | 876 1351 | 828 1278 | 811 1251 | 799 1232 | 787 1214 | 769 1187 | 757 1169 | 704 1086 | 586 904 | 462 712 | 373 575 | 302 466 | 237 365 | 189 292 | 154 237 | 124 192 | 101 155 | 65 100 | 59 91 | 53 82 |

8 | 40S 80S | .322 .500 | 873 1355 | 826 1262 | 774 1201 | 732 1136 | 716 1112 | 706 1096 | 695 1079 | 679 1055 | 669 1039 | 622 966 | 517 603 | 408 633 | 329 511 | 267 414 | 209 325 | 167 260 | 136 211 | 110 170 | 89 138 | 57 89 | 52 81 | 47 73 |

10 | 40S 80S | .385 .500 | 794 1087 | 751 1029 | 704 984 | 665 912 | 651 892 | 642 879 | 632 866 | 618 847 | 608 833 | 586 775 | 471 645 | 371 508 | 299 410 | 242 332 | 190 260 | 152 208 | 124 169 | 100 137 | 81 111 | 52 72 | 48 65 | 43 59 |

12 | 40S 80S | .375 .500 | 688 917 | 651 867 | 609 813 | 576 769 | 564 752 | 556 741 | 548 730 | 535 714 | 527 703 | 490 653 | 408 544 | 321 428 | 259 346 | 210 280 | 165 220 | 132 176 | 107 143 | 86 115 | 70 93 | 45 60 | 41 55 | 37 49 |

14 | 40S 80S | .375 .500 | 626 835 | 593 790 | 555 740 | 525 700 | 514 685 | 506 675 | 499 665 | 488 650 | 480 640 | 446 595 | 371 495 | 293 390 | 236 315 | 191 255 | 150 200 | 120 160 | 98 130 | 79 105 | 64 85 | 41 55 | 38 50 | 34 45 |

16 | 40S 80S | .375 .500 | 548 731 | 518 691 | 486 648 | 459 613 | 450 599 | 443 591 | 438 582 | 427 569 | 420 560 | 390 521 | 325 433 | 256 341 | 207 276 | 167 223 | 131 175 | 105 140 | 85 114 | 69 92 | 56 74 | 36 48 | 33 44 | 30 39 |

18 | 40S 80S | .375 .500 | 487 649 | 461 614 | 432 576 | 408 544 | 400 533 | 394 525 | 388 517 | 379 506 | 373 498 | 347 463 | 289 385 | 228 303 | 184 245 | 149 198 | 117 156 | 93 124 | 76 101 | 61 82 | 50 66 | 32 43 | 29 39 | 26 35 |

20 | 40S 80S | .375 .500 | 438 585 | 415 553 | 389 518 | 368 490 | 360 480 | 354 473 | 349 466 | 341 455 | 336 448 | 312 417 | 260 347 | 205 273 | 165 221 | 134 179 | 105 140 | 84 112 | 68 91 | 55 74 | 45 60 | 29 39 | 26 35 | 24 32 |

24 | 40S 80S | .375 .500 | 365 487 | 346 461 | 324 432 | 306 408 | 300 400 | 295 394 | 291 388 | 284 379 | 280 373 | 260 347 | 217 289 | 171 228 | 138 184 | 112 149 | 88 117 | 70 93 | 57 76 | 46 61 | 37 50 | 24 32 | 22 29 | 20 26 |

The Allowable Stress Values used are as shown in Appendix "A" of ANSI B31.3-1993 for welded pipe to ASTM A-312 having a weld joint factor of .80.

Allowable Working Pressures shown for each size reflect the minus 12½% manufacturers wall tolerance.