Welded Stainless Steel SS304 Tubing

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

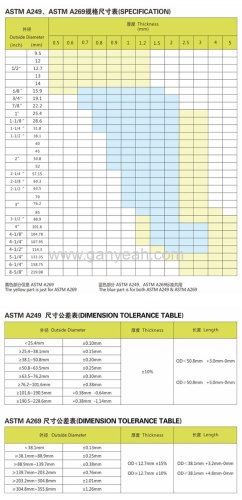

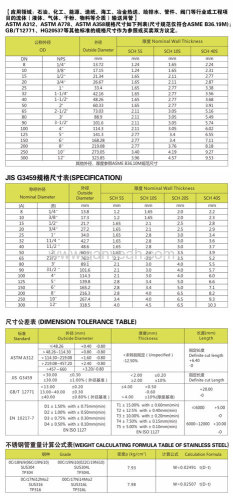

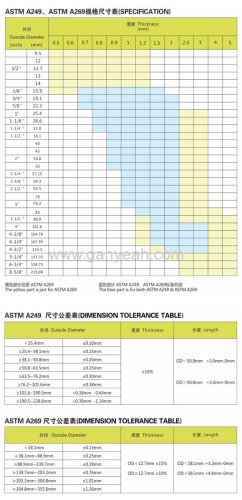

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

Welded Stainless Steel SS304 Tubing

1/4" through 16" A312, 1/2" through 54" A778

ASTM A312/ASME SA312 and ASTM A778

Schedule 5, Schedule 5S, Schedule 10, Schedule 10S, Schedule 40, and Schedule 40S.

Dual Grade 304/304L and 316/316L, straight grade available upon request.

20 foot lengths, lengths smaller and longer than 20 feet available upon request.

Material will meet the relevant specifications.

Surfaces

Surface roughness on welded tubes and pipes

Tubes and pipes can be manufactured from strip or plate with different types of surface finishes which in addition can be influenced within one pre-material type also by thickness and grade. The surface of the pre-material significantly influences the surface roughness of the final tube (given no further surface treatment like grinding / polishing / brushing etc). The surface finish is defined according to EN 10028-7:2007 (E) in table 1.

Table 1 - Type of process route of sheet, plate and strip*

| Code** | Type of treatment | Surface finish | Notes | |

| Hot rolled | 1E | Hot rolled, heat treated, mechanically descaled | Free of scale | The type of mechanical descaling, e.g. coarse grinding or shot blasting, depends on the steel grade and the product, and is left to the manufacturer's discretion, unless otherwise agreed. |

| 1D | Hot rolled, heat treated, pickled | Free of scale | Usually standard for most steel types to ensure good corrosion resistance; also common finish for further processing. It is permissible for grinding marks to be present. Not as smooth as 2D or 2B. | |

| Cold rolled | 2E | Cold rolled, heat treated, mechanically descaled | Rough and dull | Usually applied to steels with a scale which is very resistant to pickling solutions. May be followed by pickling. |

| 2D | Cold rolled, heat treated, pickled | Smooth | Finish for good ductility, but not as smooth as 2B or 2R. | |

| 2B | Cold rolled, heat treated, pickled, skin passed | Smoother than 2D | Most common finish for most steel types to ensure good corrosion resistance, smoothness and flatness. Also common finish for further processing. Skin passing may be by tension levelling. | |

| 2R | Cold rolled, bright annealed*** | Smooth, bright, reflective | Smoother and brighter than 2B. Also common finish for further processing. |

* Not all process routes and surface finishes are available for all steels.

** First digit, 1= hot rolled, 2 = cold rolled.

*** May be skin passed.

By experience we know approximately what surface roughness the coil material has before we start

forming the coil into a tube that is fusion welded. The welding method and amount of bead working

decides the roughness of the weld.

Process Welded Stainless Steel SS304 Tubing with wall thicknesses less than 2 mm are normally produced from cold rolled strip. The surface condition on the coil material these tubes are produced from is mainly 2D or 2E (brushed), depending on the grade, and have Ra-values of around 1.5.

Process pipes with wall thicknesses 2-6 mm are produced from cold rolled strip descaled with shot

blasting and then pickled (2E). These tubes have Ra-values between 2.0-5.0.

Process pipes with wall thickness above 6 mm are produced from hot rolled plate that has a

Ra roughness around 5.

Table 2 - Surface roughness of strip, sheet and plate materials used for Welded Stainless Steel SS304 Tubing

| Product | Code | Ra | Tubular Product |

| Cold rolled, pickled | 2D | ≤1.5 | Pipe and heat exchanger tubes. < 2 mm wall |

| Cold rolled, shot blast, pickled | 2E | 2.0-5.0 | Pipe and heat exchanger tubes. 2 - 6.35 mm wall |

| Hot rolled, pickled | 1D | 3.5-5.0 | Pipe > 6.35 mm wall |

Note that even if the Ra-value is the most common way to describe the roughness it is not always the most accurate. For example, a ground surface with an Ra-value of 0.8 does not look as shiny as an electro polished surface with Ra-value 0.8.