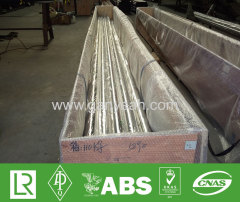

Sanitary Stainless Steel Round Tube

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

| A-270 | Specification covers seamless and welded austenitic stainless steel sanitary tubing intended for use in the dairy and food industry and having special surface conditions. Grades covered in this specification are TP 304, 304L, 316, and 316L. Includes sizes up to and including 4 inches in outside diameter. |

Sanitary Stainless Steel Round Tube------Stainless Steel Processes

The final operation after fabrication or heat treatment is cleaning to remove surface contamination and restore corrosion resistance of the exposed surfaces. Degreasing to remove cutting oils, grease, crayon markings, fingerprints, dirt, grime and other organic residues is the first step.

Sanitary Stainless Steel Round Tube Degreasing:

Non-chlorinated solvents should be used in order to avoid leaving residues of chloride ions in crevices and other locations where they can initiate crevice attack, pitting, and/or stress corrosion later on when the equipment is placed in service.

Sanitary Stainless Steel Round Tube Machined Components:

After degreasing, machined components are sometimes "passivated" in 10% nitric acid. Nitric acid enhances the natural oxide surface film.

Sanitary Stainless Steel Round Tube Fabrications:

After degreasing, metallic surface contaminants such as iron embedded in fabrication shop forming and handling, weld splatter, heat tint, inclusions and other metallic particles must be removed in order to restore the inherent corrosion resistance of the stainless steel surface.

Nitric-HF pickling, (10% HNO3, 2% HF at 49C to 60C (120 to 140F), is the most widely used and effective method removing metallic surface contamination. Pickling may be done by immersion or locally using a pickling paste.

Sanitary Stainless Steel Round Tube Electro Polishing:

Electro polishing is using oxalic or phosphoric acid for the electrolyte; a copper bar or plate for the cathode can be equally effective. Electro-polishing may be done locally to remove heat tint alongside of welds or over the whole surface.

Both pickling and electro polishing remove a layer several atoms deep from the surface. Removal of the surface layer has the further benefit of removing surface layers that may have become somewhat impoverished in chromium during the final heat treatment operation.