304 316 Stainless Steel Bright Annealing Pipe&Tubing

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

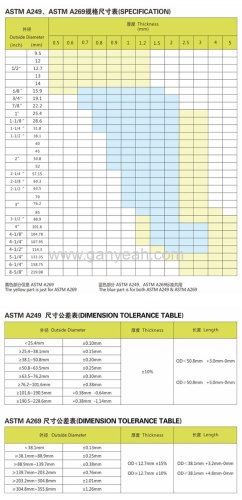

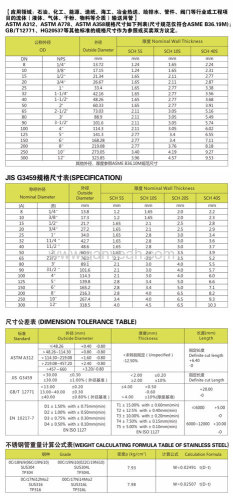

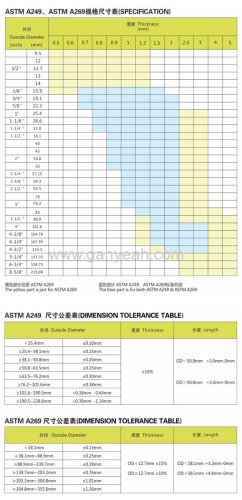

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

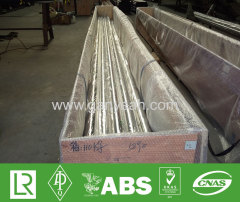

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

Intergranular Corrosion – Corrosion that occurs at the grain boundaries in austenitic stainless steels that have been heated to and held at temperatures between 850° F and 1450° F. Slow cooling through this range can also result in sensitization to intergranular corrosion. Usually caused by precipitation of chrome carbides.

ISO (International Organization for Standardization) – Prepares specifications. Both Canada and the U.S.A. are ISO members and participate in the ISO specification development.

Mean Coefficient of Thermal Expansion – A measure of the incremental change in size of a material experienced when it is subjected to a temperature change. It is measured in inches/inch/ °F. This number multiplied by the length of the tubing (in inches) and by the temperature change (in °F) indicates how much the tube length will change (in inches). If the temperature decreases, the tube will shrink by a similar amount.

Modulus of Elasticity – A ratio of stress to strain. Used in engineering calculations to determine rigidity and deflection under load. The higher the number, the more rigid the item will be for a given load. The units are in pounds per square inch (psi).

Roughness Average (Ra) – An expression of measured surface roughness or texture, typically, of a polished or machined metal surface. The arithmetic average value of the departure (peaks and valleys) of a surface profile from the center-line throughout the sampling length, generally expressed in micro-inch (0.000,001-inch) or micro-meter (or micron) (0.0003937-inch) units.

Schedule,Pipe – A means of indicating the wall thickness of pipe sizes, as set forth in ASME B36.1 and ASTM A530 and B775. Commonly available pipe schedules are Schedules 5, 10, 20, 40, and 80. The actual wall thickness of a schedule number varies with the nominal pipe size or diameter (e.g.: 1/2" Sch 40 = 0.109" while 2" Sch 40 = 0.154"). A higher number schedule indicates a thicker wall for a particular pipe diameter. (See page 12).