SA 304 stainless steel Tubing

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

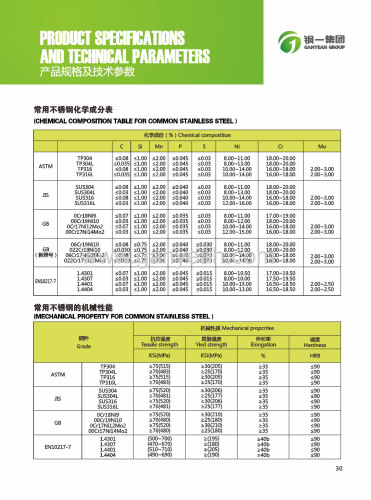

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

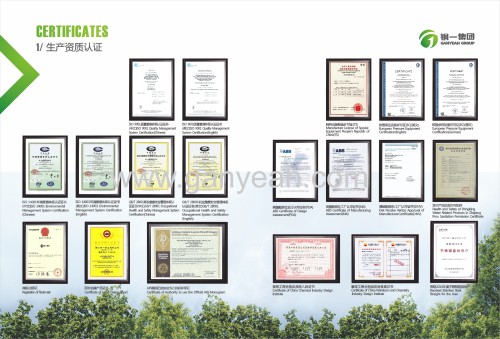

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

High Purity Service

Mechanically SA 304 stainless steel Tubing to 3A and ASTM A270 Specifications

Dairy, Food and Beverage Applications

GANYEAH's SA 304 stainless steel Tubing is available in 1/2" (12.7 mm) to 4" (101.6 mm) OD sizes. Stocked in standard box quantities for same day shipping in both 304L and 316L in 20 ft. (6.1 m) lengths. Tubing surfaces are available bright annealed or mechanically polished ID to 20 µ-in Ra (0.5 µm) maximum and/or OD polished to 30 µ-in Ra (0.8 µm) maximum surface roughness with ends prepared for automatic orbital welding. This SA 304 stainless steel Tubing is protected in heat sealed

poly sleeves to prevent contamination, then packaged in sturdy triple-wall cardboard boxes for optimum protection.

Request Technical Bulletin:

3A Sanitary Stainless Steel Tubing

High Purity Service

Mechanically Polished, ID & OD Cleaned For High Purity Service To BPE Specifications

Pharmaceutical, Biotechnology, other High Purity Applications

Tubing specifically manufactured to the stringent ASME BPE and ASTM A270 S2 standards in 1-1/2" (38.1 mm) to 4"

(101.6 mm) OD, 20 ft. (6.1 m) lengths in 316L.

One hundred percent bore-scoped and mechanically polished to 20 µ-in Ra (0.5 µm) ID maximum and 30

µ-in Ra (0.8 µm) OD maximum surface roughness with ends prepared for automatic orbital welding. Standard packaging consists of ID cleaning in a certified Class 100 Cleanroom (Fed 209E) for high purity use utilizing a 99.9999% pure electronics grade nitrogen purge, plastic capped ends, heat sealed 6-mil poly sleeves and wood boxes for shipment.