310 Stainless Steel Pipe Welding

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

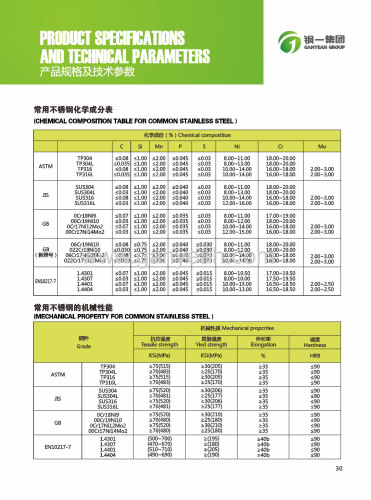

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

310 Stainless Steel Pipe Welding | ||

Fortunately, the wide acceptance of welded stainless steel | ||

tubing and standardization within the metals fabrication industry | ||

has simplified tube selection. Outside diameter and gage is used | ||

to specify sanitary tubing. Sixteen-gage tubing is used for the vast | ||

majority of applications, except those with large-diameter and/or | ||

higher product pressures. Specifications for 310 Stainless Steel Pipe Welding are | ||

shown in table 4. Tubing is manufactured according to ASTM | ||

A270 "Specification for Seamless and Welded Austenitic Steel | ||

Sanitary Tubing." | ||

Sanitary Pipeline Fittings are manufactured by a long list of | ||

companies utilizing a number of joint styles and sealing techniques | ||

including (in no particular order): Tri-Clamp or "clamp," Butt-weld, | ||

Bevel Seat, DC, H-Line, HDI-Line, John Perry, S-Line, and I-line. | ||

Fitting types have been developed specifically for certain industries, | ||

manufacturers and user groups. Adaptors to connect different types | ||

of fittings are sometimes available, as well as adaptors to connect | ||

fittings to non-sanitary piping such as flanges, pipe thread, pipe OD | ||

(compression fitting) and other items. The system designer must | ||

select carefully, especially when mating new piping to existing | ||

piping and equipment. | ||

What's the difference between tube and pipe? | ||||||

Tube is manufactured to a set outside diameter and wall | ||||||

thickness (e.g. 1.5" OD, 0.065" wall), while pipe is specified by a | ||||||

"nominal" (not actual) inside diameter. The wall thickness of pipe | ||||||

is described by the "schedule". For example, schedules 5 and 40 | ||||||

pipe have wall thicknesses of 0.065" and 0.109" respectively. | ||||||

Food-Grade Gasket Materials | ||||||

As specified by the 3-A standards, food-grade rubber and | ||||||

plastic material can be used for gaskets in sanitary joints. Table 6 | ||||||

lists selected 3-A approved commercial gasket materials and their | ||||||

working temperature range. | ||||||