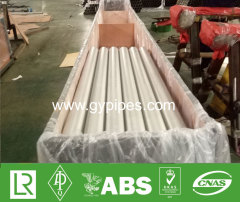

316s Stainless Steel Welded Pickled Pipe

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

CHARACTERISTICS

316s Stainless Steel Welded Pickled Pipe is used for applications that require the high strength, toughness and workability, coupled with increased corrosion resistance. The alloy contains higher percentages of molybdenum and nickel than 304 stainless pipe, increasing the corrosion resistance and making it an ideal material for applications in aggressive environments.

APPLICATIONS

316s Stainless Steel Welded Pickled Pipe is used for pressure operations to move liquids or gases in water treatment, waste treatment, petrochemical, chemical and pharmaceutical industries. Structural applications include handrails, poles and support pipe for salt water and corrosive environments. It is not used as often as welded pipe due to its reduced weldability compared to 304 stainless unless its superior corrosion resistance outweighs it decreased weldability.

SIZES

1/2" thru 2" Schedule 40 X 20' Randoms

TYPICAL CHEMICAL PROPERTIES

Carbon, Max % | 0.03 |

Manganese, Max % | 2.00 |

Phosphorus, Max % | 0.045 |

Sulphur, Max % | 0.03 |

Chromium, Max% | 18.0 |

Nickel, Min% | 14.0 |

Molybdenum, Max% | 3.0 |

TYPICAL MECHANICAL PROPERTIES

Tensile Strength ksi | 83 |

Yield 2% Offset ksi | 38 |

Elongation in 2" (50.80mm) | 50 |

Call today for a quote for 316 / 316L stainless steel pipe

Welded steel pipe weight kg/m = (Od - Wt) * Wt * 0.02466 note: where Od is the outer diameter Wt is wall thickness

| Nominal diameter | Common tube | Thickening tube | ||||

(mm) | (in) | external diameter(mm) | wall thickness(mm) | Theoretical weight(kg/m) | wall thickness(mm) | Theoretical weight (kg/m) |

6 | 1/8 | 10 | 2.00 | 0.39 | 2.5 | 0.46 |

8 | 1/4 | 13.5 | 2.25 | 0.62 | 2.75 | 0.73 |

10 | 3/8 | 17 | 2.25 | 0.82 | 2.75 | 0.97 |

15 | 1/2 | 21.25 | 2.75 | 1.26 | 3.25 | 1.45 |

20 | 3/4 | 26.75 | 2.75 | 1.63 | 3.5 | 2.01 |

25 | 1 | 33.5 | 3.25 | 2.42 | 4 | 2.91 |

32 | 1 1/4 | 42.25 | 3.25 | 3.13 | 4 | 3.78 |

40 | 1 1/2 | 48 | 3.5 | 3.84 | 4.25 | 4.58 |

50 | 2 | 60 | 3.5 | 4.88 | 4.5 | 6.16 |

65 | 2 1/2 | 75.5 | 3.75 | 6.64 | 4.5 | 7.88 |

80 | 3 | 88.5 | 4 | 8.34 | 4.75 | 9.81 |

100 | 4 | 114 | 4 | 10.85 | 5 | 13.44 |

125 | 5 | 140 | 4 | 13.42 | 5.5 | 18.24 |

150 | 6 | 165 | 4.5 | 17.81 | 5.5 | 21.63 |