Stainless Steel Mig Welding Gas Tube

3500.0 USD

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

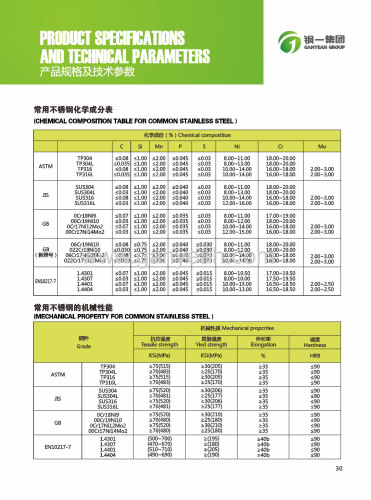

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

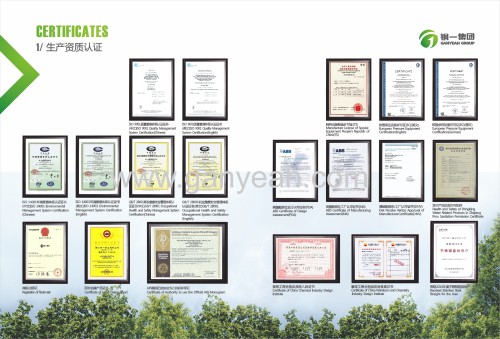

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

Specifications Materials Stainless Steel Mig Welding Gas Tube Solutions

| Brands | GANYEAH Tube® |

| Wall Thickness | < 0.05 to 3.8 mm < 0.002 to 0.150 in |

| Outer Diameter of Tube | 0.010 to 1.5 Inch 0.25 to 38.1 mm |

| Maximum Length of Straight Tubes | 45 ft 14 m |

| Materials Overview | Precision Metal Tubing in an extensive range of specialty grades of Stainless Steel, Duplex Stainless Steel, Nickel, Titanium and Zirconium. |

| Stainless Steel Tubing Materials | 304 304L 310 316 316L 316LN 316LVM 316TI 317L 321 347 Duplex S31803 Super Duplex (S32750 and S32760) |

| Industries Served | Aerospace Precision Components Nuclear Oil & Gas Medical Chemical Process |

| Oil and Gas | For the most challenging subsea and downhole conditions including seawater, high temperature and sour oil well environments we use materials such as austenitic, super austenitic, duplex and super duplex stainless steels, as well as titanium and nickel alloys for our tubing. Seamless tubes are mainly used for hydraulic and instrumentation applications, in onshore control panels, topside processing facilities, on subsea manifolds and templates. Applications for seam welded and redrawn tubes are umbilicals, subsea control lines and chemical injection tubes. |

| Energy | As long established suppliers to the nuclear industry, our core products include specialised stainless steel tubes for fuel rods, control rods and tie bars. We also manufacture precision tubes in zirconium alloys for fuel cans, in nickel alloys for heat exchangers and in titanium alloys for the fabrication of condensers. Superior Tube has a long history working with the US Government on nuclear energy projects. We've manufactured many of the components listed above to meet rigorous federal specifications. |

| Aerospace | We develop high strength tubing for aircraft engines and airframes in today's leading military and civil aircraft programmes. This includes tubing for hydraulic and pneumatic control systems, torque control rods, transmission, landing gear and instrumentation. Our materials such as titanium 3Al-2.5V, titanium 6Al-4V and Ti CP offer excellent strength/weight ratios for 3,000 or 5,000 psi systems. We also specialise in high temperature nickel alloys and stainless steel grades such as 21-6-9. Besides our AS9100 approved quality system, we have NADCAP certification on heat treatment and non-destructive testing. |

| Medical | Medical tubes are used in critical cardiovascular and trauma procedures. Our process capability delivers precise control of tube dimensions. We supply high specification tubing for heart valves, trauma and orthopaedic implants, surgical instruments, catheters, stents and orthodontic applications. Materials include a range of titanium alloys along with conventional or vacuum melt stainless steels in circular or bespoke profiles. |

| Chemical Process | High quality tubes in the chemical process industry are used in a variety of applications, such as flow meters, measurement systems, condenser tubes, shell and tube heat exchangers, paper production and acetic acid alloy plants. Typical materials include austenitic stainless grades in standard or modified analysis, as drawn or electropolished. |

| Production Facilities | Pilger mills Multi-roll rolling mills Draw benches Tube welding mills - In-line weld mills Controlled atmosphere heat treatment Bright annealing/hydrogen furnace Vacuum annealing Pickling and passivation plant Non-Destructive Testing (NDT) ultrasonic and eddy current testing Hydrostatic testing Radiographic examination Electropolishing capabilities Full chemical and physical laboratory analysis |

| Global Presence | Superior Tube and UK-based sister company, Fine Tubes, are part of AMETEK Specialty Metal Products, a division of AMETEK, Inc., a leading global manufacturer of electronic instruments and electromechanical devices. In addition to tube mills in the United States and United Kingdom, we have sales offices in Germany, France, India, Taiwan and the United States, as well as an extensive network of partners in Asia, Europe and the Middle East. Our tubing experts deliver high precision tubing to customers in over 35 countries worldwide. |

REQUEST FOR QUOTE

Product Line Description

GANYEAH Tube is a leading global manufacturer of precision engineered, Stainless Steel Mig Welding Gas Tube in a wide range of stainless steel. Offering over 10 years of engineering expertise, Superior Tube works closely with customers worldwide, developing high specification tubing solutions to help them solve their technical challenges.

Stainless steel tubes

Seamless, welded or welded & redrawn (Weldrawn®)

Size range from under 0.010" (1/4 mm) up to 1.5" (38.1mm) outside diameter

Straight lengths up to 45ft (14m) in length

Coiled tubes up to 3,200ft (975m) in length

.jpg)

.jpg)