Erw Schedule 40 316 Stainless Steel Pipe

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

Description:

GANYEAH GROUP is a leading supplier and manufacturer of ASTM A312 welded stainless steel round pipe for Oil & Gas industries, GANYEAH's welded stainless steel round pipe is widely used in Oil & Gas industries all over the world. It is certified to the requirements of ASTM A312, ASME SA312, ASTM A358, ASTM A778, ANSI B36.19/M standards and most user specifications. Our welded stainless steel round pipe is manufactured from the finest quality raw materials made exclusively to GANYEAH melt parameters.

During the past several years, our customers have come to rely on the quality of our welded stainless steel round pipe products as well as our uncompromised commitment to total customer satisfaction.

We stock all ASTM A312 A358 A778 Erw Schedule 40 316 Stainless Steel Pipe from NPS 1/4''(13.72mm) to 8''(219.08mm) in 20ft. standard lengths, grades TP304/304L & TP316/316L. Custom lengths and sizes are available upon request.

Materials:

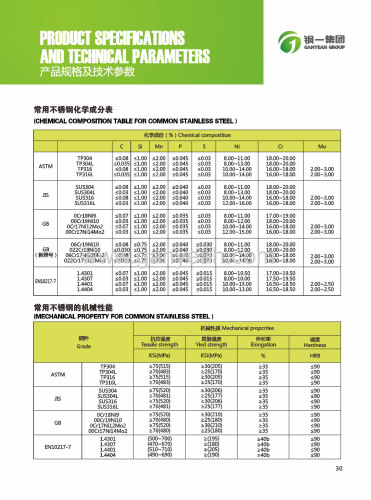

TP304/304L, TP316/316L. Other grades are available upon customer's request.

Size Range:

NPS/OD 1/4'' (13.72MM) - 84'' (2133.60MM), WT SCH5S - XS.

Manufacturing Method:

TIG Welding or TIG+Plasma, Annealed & Pickled.

Surface Finishes:

Surface finish is annealed & pickled. Other finishes available upon request.

Quality and Mechnical Tests:

To assure the highest quality standards, our Erw Schedule 40 316 Stainless Steel Pipe is subjected to extensive testing and inspection programs that meet or exceed ASTM A312/A999/A999M test requirements. Testing includes reverse bend, reverse flattening, and flange tests. Eddy current testing is performed on 100% of the AISI 304 ASTM Erw Inox Steel tubing produced.

Marking:

ASTM A312 welded stainless steel round pipe is line stenciled with OD, wall, ASTM specifications, size, grade, heat number, production date and time.

ASTM A312 TP304/304L 10'' X SCH-40S X 20' HEAT NO.XXXXX

Packaging:

Erw Schedule 40 316 Stainless Steel Pipe is normally packed in bundles, when specified, wooden boxes and all export requirements can be provided.

Quality Assurance:

All our finished products undergo extensive and strict quality tests before being delivered to our customers. Mill Test Certificate EN10204 3.1 or EN10204 3.2 which contains the result of the mechanical tests and hydrostatic test will be provided to our customers.

1. Chemical Analysis

2. Eddy Current

3. Hydrostatic Test

4. Flattening Test

5. Elongation Test

6. Yield Strength Test

7. Hardness Test

8. Tensile Test

Specifications:

| ASTM A312 Welded Stainless Steel Round Pipe Chemical Requirements (wt%) | ||||

| Elements | TP304 | TP304L | TP316 | TP316L |

| C Max. | 0.08 | 0.030 | 0.08 | 0.030 |

| Mn Max. | 2.00 | 2.00 | 2.00 | 2.00 |

| P Max. | 0.045 | 0.045 | 0.045 | 0.045 |

| S Max. | 0.030 | 0.030 | 0.030 | 0.030 |

| Si Max. | 1.00 | 1.00 | 1.00 | 1.00 |

| Cr | 18.0-20.0 | 18.0-20.0 | 16.0-18.0 | 16.0-18.0 |

| Ni | 8.0-11.0 | 8.0-13.0 | 10.0-14.0 | 10.0-14.0 |

| Mo | 2.0-3.0 | 2.0-3.0 | ||

| N | ||||

| Cu | ||||

| Other | ||||

| ASTM A312 Welded Stainless Steel Round Pipe Dimensional Tolerances | |||

| Size NPS | Outside Diameter(MM) | Length(MM) | Wall (MM) |

| 1/4'' to 11/2'' (13.72 to 48.26), incl | +0.4/-0.8 |

+6.0/-0

| +/-12.5% |

| Over 11/2'' to 4'' (48.26 to 114.3), incl | +/-0.8 | +/-12.5% | |

| Over 4'' to 8'' (114.3 to 219.08) incl | +1.6/-0.8 | +/-12.5% | |

| Over 8'' to 18'' (219.08 to 457.2), incl | +2.4/-0.8 | +/-12.5% | |

| Over 18'' to 26'' (457.2 to 660.4), incl | +3.2/-0.8 | +/-12.5% | |

| Over 26'' to 34'' (660.4 to 863.6), incl | +4.0/-0.8 | +/-12.5% | |

| Over 34'' | +4.8/-0.8 | +/-12.5% | |

| ASTM A312/A358/A778, ASME B36.19M/ASME B36.10M | ||||||||||

| Nominal Diameter NPS | Outside Diameter (mm) | Nominal Wall Thickness (mm) | ||||||||

| ASME B36.19M | ASME B36.10M | |||||||||

| SCH-5S | SCH-10S | SCH-40S | SCH-80S | SCH-5 | SCH-10 | SCH-20 | STD | XS | ||

| 1/4 | 13.72 | - | 1.65 | 2.24 | 3.02 | - | 1.65 | - | 2.24 | 3.02 |

| 3/8 | 17.15 | - | 1.65 | 2.31 | 3.20 | - | 1.65 | - | 2.31 | 3.20 |

| 1/2 | 21.34 | 1.65 | 2.11 | 2.77 | 3.73 | 1.65 | 2.11 | - | 2.77 | 3.73 |

| 3/4 | 26.67 | 1.65 | 2.11 | 2.87 | 3.91 | 1.65 | 2.11 | - | 2.87 | 3.91 |

| 1 | 33.40 | 1.65 | 2.77 | 3.38 | 4.55 | 1.65 | 2.77 | - | 3.38 | 4.55 |

| 11/4 | 42.16 | 1.65 | 2.77 | 3.56 | 4.85 | 1.65 | 2.77 | - | 3.56 | 4.85 |

| 11/2 | 48.26 | 1.65 | 2.77 | 3.68 | 5.08 | 1.65 | 2.77 | - | 3.68 | 5.08 |

| 2 | 60.33 | 1.65 | 2.77 | 3.91 | 5.54 | 1.65 | 2.77 | - | 3.91 | 5.54 |

| 21/2 | 73.03 | 2.11 | 3.05 | 5.16 | 7.01 | 2.11 | 3.05 | - | 5.16 | 7.01 |

| 3 | 88.90 | 2.11 | 3.05 | 5.49 | 7.62 | 2.11 | 3.05 | - | 5.49 | 7.62 |

| 31/2 | 101.60 | 2.11 | 3.05 | 5.74 | 8.08 | 2.11 | 3.05 | - | 5.74 | 8.08 |

| 4 | 114.30 | 2.11 | 3.05 | 6.02 | 8.56 | 2.11 | 3.05 | - | 6.02 | 8.56 |

| 5 | 141.30 | 2.77 | 3.40 | 6.55 | 9.53 | 2.77 | 3.40 | - | 6.55 | 9.53 |

| 6 | 168.28 | 2.77 | 3.40 | 7.11 | 10.97 | 2.77 | 3.40 | - | 7.11 | 10.97 |

| 8 | 219.08 | 2.77 | 3.76 | 8.18 | 12.70 | 2.77 | 3.76 | 6.35 | 8.18 | 12.70 |

| 10 | 273.05 | 3.40 | 4.19 | 9.27 | 12.70 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 |

| 12 | 323.85 | 3.96 | 4.57 | 9.53 | 12.70 | 3.96 | 4.57 | 6.35 | 9.53 | 12.70 |

| 14 | 355.60 | 3.96 | 4.78 | 9.53 | 12.70 | 3.96 | 6.35 | 7.92 | 9.53 | 12.70 |

| 16 | 406.40 | 4.19 | 4.78 | 9.53 | 12.70 | 4.19 | 6.35 | 7.92 | 9.53 | 12.70 |

| 18 | 457.20 | 4.19 | 4.78 | 9.53 | 12.70 | 4.19 | 6.35 | 7.92 | 9.53 | 12.70 |

| 20 | 508.00 | 4.78 | 5.54 | 9.53 | 12.70 | 4.78 | 6.35 | 9.53 | 9.53 | 12.70 |

| 22 | 558.80 | 4.78 | 5.54 | - | - | 4.78 | 6.35 | 9.53 | 9.53 | 12.70 |

| 24 | 609.60 | 5.54 | 6.35 | 9.53 | 12.70 | 5.54 | 6.35 | 9.53 | 9.53 | 12.70 |

| 26 | 660.40 | - | - | - | - | - | 7.92 | 7.92 | 9.53 | 12.70 |

| 28 | 711.20 | - | - | - | - | - | 7.92 | 7.92 | 9.53 | 12.70 |

| 30 | 762.00 | 6.35 | 7.92 | - | - | 6.35 | 7.92 | 7.92 | 9.53 | 12.70 |

| 32 - 84 | 812.80 - 2133.60 | Thickness :6.35~30mm | ||||||||

| Remark | (1)Marking:Within production capability. (2)Other nominal diameter and wall thickness subject to the approval of vendor and purchaser. (3)Calculating formula for the value of mass (kg/m):304/L[W=0.02491t(D-t)], 316/L[W=0.02507t(D-t)] | |||||||||

Applications:

1. Oil & Gas Industry

2. Chemical & Petro Chemical Industry

3. Shipbuilding

4. Desalination

5. Water Treatment

6. Energy