ASTM A312 grade 316l stainless steel

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

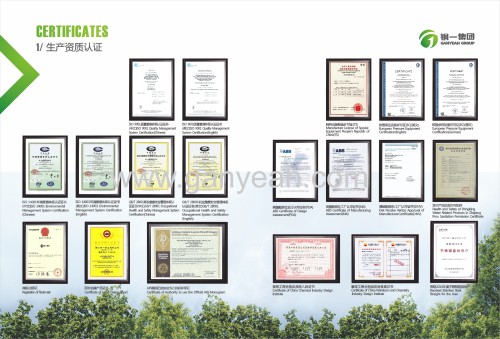

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

The welding process is one of the core ways in which we manufacture precision tubes. Our high quality ASTM A312 grade 316l stainless steel starts off as a flat strip of metal. The strip is formed into a tube through a series of rollers and the join, also called the seam, is then welded together.

Special non-destructive testing methods – including eddy current, ultrasonic and pressure testing - are used to ensure a consistent weld. Just like with seamless manufacturing, welded tubes can be drawn down by plug drawing or sinking. This method can be used to create very long lengths of coiled tube.

The main ASTM A312 grade 316l stainless steel manufacturing processes used are strip welding and cold drawing, but other important processes in between, or at the end of the drawing process,

OUR WELDING CAPABILITIES

Single torch TIG welding for high quality products with maximum reliability and process stability. A range of specialist welding gases are available for autogenous welding conducted in an inert atmosphere.

Multi-torch welding affords a very versatile torch set-up and enables us to weld with various configurations, on one line. We use this for specialist applications.

Plasma welding means lower heat input than TIG welding, and is used for specialist applications where there are specific metallurgical and/or weld profile requirements. A range of gas mixtures are available to meet specific technical and customer requirements.

Fine Tubes also has advanced post-weld bead rolling capability and advanced post-weld cross-sectional weld and parent metal cold work facilities.

We also have autogenous orbital welding equipment and facilities. Post weld heat treatment is an option. We can also control the orbital weld profile to give zero bore weld protrusion. All welding is conducted in an inert atmosphere and all welds are fully X-ray and pressure tested.

Orbital welding with cold-wire feed allows for weld reinforcement with a low heat input.

DRAWING PROCESSES

After welding, we can draw the tube down to alter its size and shape. Both sink drawing and plug drawing are used. The plug is not attached in this case, but 'floating'. This means it balances in position, being pulled forward by the tube being drawn, while at the same time it's pushed back as it tries to pass through the dies.

Between each draw the tube is degreased, annealed and tagged for the next draw. Welded tube as well as long lengths of seamless tube can be drawn on to coils.