Astm a270 stainless tube welding

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730611 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

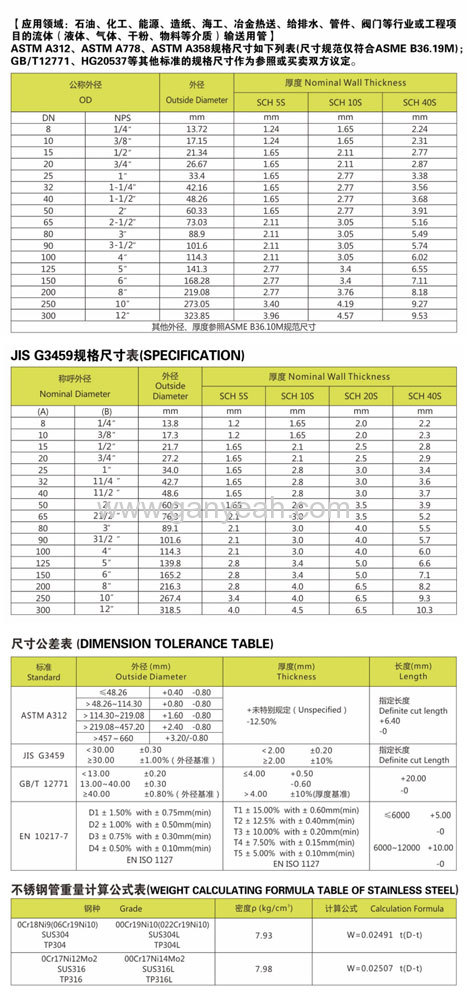

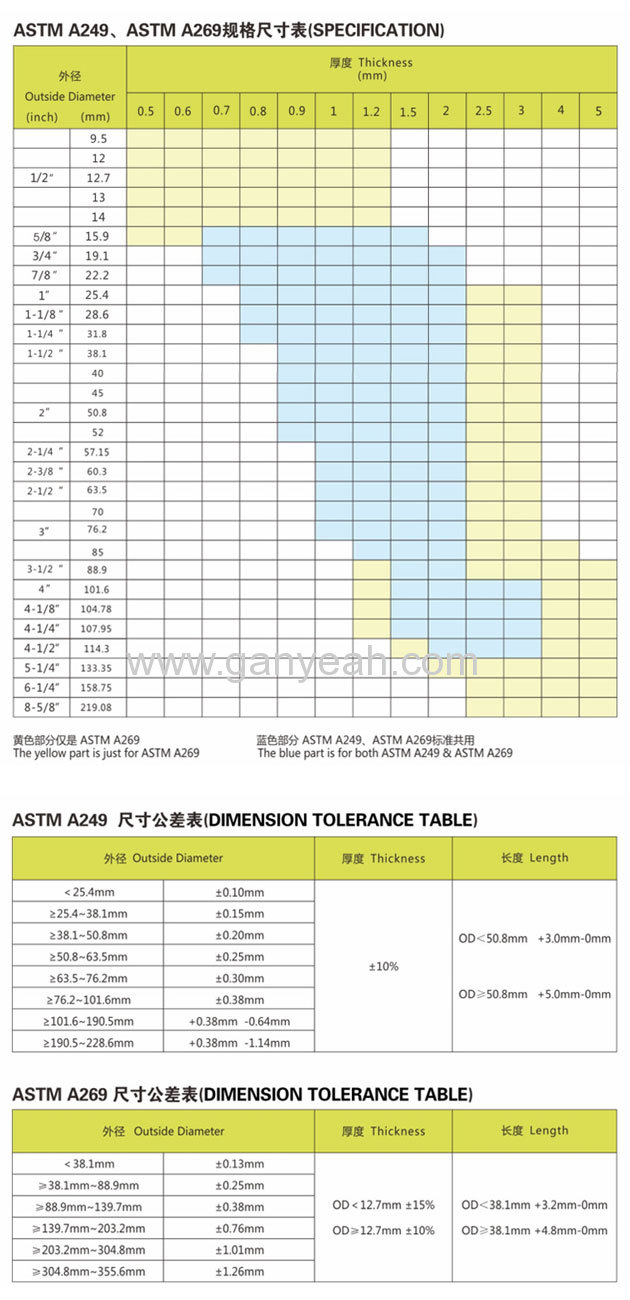

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

Name | Astm a270 stainless tube welding | ||

Standard | ASTM A554, A312, A249, A269 and A270 | ||

Material Grade | 304,304L,316,316L | ||

Outer Diameter | 6mm-2020mm | ||

Thickness | 0.8mm - 60mm | ||

Length | 6m or as customers' request | ||

Tolerance | a) Outer Diameter: +/- 0.2mm | ||

b) Thickness: +/- 0.02mm | |||

c) Length: +/- 5mm | |||

Surface | 180G, 320G Satin / Hairline(Matt Finish, Brush, Dull Finish)400G, 600G Mirror finish | ||

Application | Fluid and gas transport,decoration, construction,medical equipment, aviation, boiler heat-exchanger and other fields | ||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||

Payment | 30% T/T as deposit, the balance before shipment or L/C. | ||

Delivery time | 10~30 days ,according to the order quantity | ||

Packing | Bundled with knitted plastic bag, wooden cases or according to customers' request. | ||

Mechanical Property | Material Item | 304 | 316 |

Tensile Strength | ≥520 | ≥520 | |

Yield Strength | ≥205 | ≥205 | |

Extension | ≥35% | ≥35% | |

Hardness (HV) | ≤90 | ≤90 | |

Astm a270 stainless tube welding chemical composition

Grade | Chemical Composition % | ||||||||

C | Cr | Ni | Mn | P | S | Mo | Si | N | |

0Cr18Ni9 (304) | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.03 | ≤1.0 | ||

00Cr18Ni10 (304L) | ≤0.03 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.03 | ≤1.0 | ||

0Cr17Ni12Mo2 (316) | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.035 | ≤0.03 | 2.003.00 | ≤1.0 | |

0Cr17Ni14Mo2 (316L) | ≤0.03 | 16.00-18.00 | 12.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.0 | |

The stainless tubes and pipes is made from stainless steel by electric welding or sheet metal strips by means of forming and welding. Electrically welded tube is made of thermally without subsequent processing and hot-reducing.

Astm a270 stainless tube welding

1. Thickness: 6mm-2020mm

2. OD range: 0.8mm - 60mm

Applications of Astm a270 stainless tube welding

1.Construction: Architectural decoration , banister, city-scape .etc

2.Food producing equipment::such as beer brewing, milk processing & wine making .etc

3.Medical field: medical instruments

4.Fluid transport-pipeline: fluid pipe ,pressure pipe ,pipe for mechanical structure , including for transport

5.Heat Exchanger tube

Packing and Label

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions. Special packing is available as per customer's requirement.

.jpg)