Quartz infrared heater for glass drying process

| Min. Order: | 20 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, T/T |

| Supply Ability: | 60,000-80,000 pieces per month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | CFIR332120W |

|---|---|

| Means of Transport: | DHL. FedEx, Air |

| Type: | Carbon IR emitter |

| Quartz material purity: | 99.97%-99.99% |

| Coating reflector: | Gold reflector |

| Tube diameter: | 33*15 |

| Power: | 300-12000W |

| Voltage: | 80-600V |

| Total length: | 120-3200mm |

| Heated length: | 70-3100mm |

| Response time: | 2-10s |

| Cable length: | 700mm |

| Production Capacity: | 60,000-80,000 pieces per month |

| Packing: | Wooden Crate with shock resistance |

| Delivery Date: | 5-15 days |

Product Description

Fast response Carbon heating element far infrared lamp

Carbon heating element far infrared lamp features:

Wavelength range of Carbon red heating IR heater: 2.5-2.7 um.

Cross sectionof Carbon red heating IR heater: 33*15mm twin tube diameter.

Applied industry: Printing painting drying, powder coating drying, Paint drying,

IR Oven Infrared oven IR furnace Infrared furnace Infrared heating equipment Infrared drying

machine Shortwave infrared oven Medium wave IR oven tunnel oven Autoclave Oven Flat Press

machine PET blow machine Flat glass press machine Laminated glass Heating Oven

Screen printing glass Drying machine Auto glass printing drying equipment

Carbon red heating IR heater model CFIR332120W

Lamp Model: CFIR332120W

Quartz tube: Gold coating

Lamp length: 2100mm

Active length: 2000mm

Volatge: 400V

Power: 4800W

Cable length: 500mm one side out

Color temperature: 1800-2400K

Wavelength of IR radiation: 2.5-2.7um

Carbon red heating IR heater

Max Heated length 2100mm

Max Total length 2200mm;

Max Power Output: 9000-12000W;

Max Voltage: 600V;

Average Lifetime of Carbon red heating IR heater: 10,000 hours

Part No.

| Voltage | Wattage | Twin tube | Total length | Model No. | |

v | w | mm | mm | Gold/White | ||

1 | 230 | 450 | 23*11 | 450 | CFIR23450G | |

2 | 230 | 500 | 23*11 | 405 | CFIR23405G | |

3 | 230 | 1500 | 23*11 | 800 | CFIR23800G | |

4 | 230 | 2100 | 23*11 | 750 | CFIR23750G | |

5 | 230 | 1800 | 23*11 | 650 | CFIR23650G | |

6 | 230 | 1600 | 23*11 | 620 | CFIR23620G | |

7 | 115 | 600 | 23*11 | 305 | CFIR23305G | |

8 | 230 | 800 | 23*11 | 545 | CFIR23545G | |

9 | 230 | 750 | 23*11 | 620 | CFIR23620G | |

10 | 230 | 1250 | 23*11 | 500 | CFIR23500G | |

11 | 220 | 1750 | 15*33 | 400 | CFIR33750G | |

12 | 415 | 1350 | 15*33 | 1050 | CFIR331050G | |

13 | 230 | 1200 | 33*15 | 700 | CFIR23700G | |

14 | 230 | 1500 | 15*33 | 800 | CFIR33800W | |

15 | 230 | 2000 | 15*33 | 1200 | CFIR331200W | |

16 | 230 | 2450 | 15*33 | 1400 | CFIR331400G | |

17 | 230 | 3450 | 15*33 | 1520 | CFIR331520G | |

18 | 230 | 3650 | 15*33 | 1600 | CFIR331600G | |

19 | 380 | 4800 | 15*33 | 2350 | CFIR332350G | |

20 | 400 | 4200 | 15*33 | 1900 | CFIR331900G | |

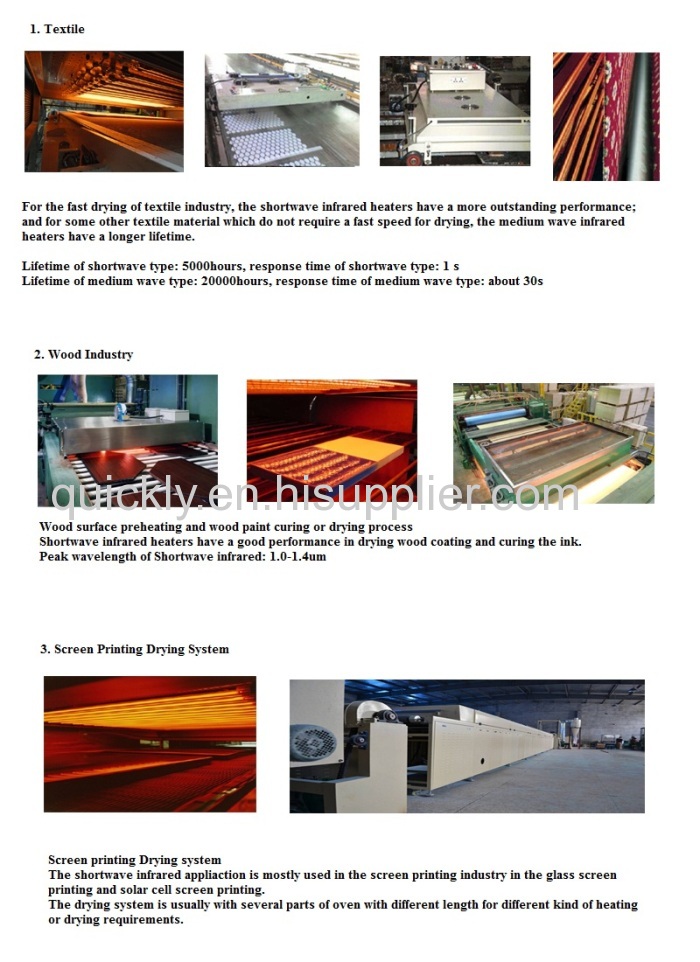

Application of Carbon heating element far infrared lamp

Film stretching machine Food Drying system Infrared food oven

Leather stamping heating equipment Plastic thermoforming system

Infrared drying system for powder coating system Car paint curing or drying with infrared system

PCB printing drying process Electronics panel preheating

The IR Heater Range | Format | Heated Length | Total Length | Max. Output | |

Short Wave IR | Halogen NIR | 10/11/12 dia. | 60-1000 | 110-1100 | 9000 |

Single-tube IR | 13/15dia. | 60-1200/1400 | 110-1300/1500 | 7500 | |

Twin-tube IR | 23x11 | 80-3000 | 200-3150 | 14,000 | |

Twin-tube IR | 33x15 | 80-3800 | 200-4050 | 16,000 | |

Carbon IR | Round tube | 12/15/18 dia. | 120-1000/1680 | 130-1200/1750 | 7,200 |

Twin-tube IR | 23x11 | 80-2500 | 200-2650 | 8,000 | |

Twin tube | 33 x 15 | 120-3000 | 130-3130 | 10,500 | |

Fast Medium wave IR | Single tube | 13/15dia. | 60-1200/1400 | 110-1300/1500 | 6,200 |

Twin-tube IR | 33x15 | 400-3000 | 600-3150 | 12,000 | |

Medium Wave IR | Single tube | 15/18dia | 80-1400/1700 | 150-1500/1800 | 6,750 |

Twin-tube IR | 18x8 | 80-1500 | 100-1600 | 2500 | |

Twin-tube IR | 23x11 | 100-2000 | 120-2200 | 4500 | |

Twin-tube IR | 33x15 | 500-5800 | 350-6000 | 12,000 | |

Our Company Core Competence:

1. Over 12 years' manufacturing experience;

2. 3 mechanical engineers and 2 electrial engineers consisting of the technical team;

3. Secure QC department and requirements for a quality guarantee;

4. Certifacte of CE, ROHS, ISO9001, etc.

Production, Packing and Delivery Process:

The spring red carbon heating element as followed:

The thick carbon material can make into high power:

Wood crate photo-shoot and packing and Shipping:

About the delivery for the carbon infrared emitters: usually it will be dleivered by FedEx, TNT,

DHL, SF Express, UPS, Airline, or by sea.

Contact us

Company Name: Hefei Quickly Electric Co., Ltd.

Company address: Jiahai Industrial Zone C-34, Xinbengbu Road,

Xinzhan District, Hefei, China