industrial printing oven infrared heating lamps

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 10000 pieces per month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | KKLT325 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand: | QUICKLY |

| Type: | Twin Tube Short Wave IR Lamp |

| Warranty Time: | 5000-20000 Hours |

| Certificate: | CE,ROHS, ISO9001 |

| Power: | 500w/1100w/2500w/3500w |

| Voltage: | 90v/120v/220v/230v/240v/380v/440v/ |

| Quartz Tube: | 99.97-99.99% purity |

| Cable Wire: | Teflen / UL textile wire / High Temperature Resistant wire |

| heating filament: | tungsten |

| Color: | clear/gold/white |

| Production Capacity: | 10000 pieces per month |

| Packing: | EPE and plywooden case |

| Delivery Date: | 5 working days after receving deposit |

Product Description

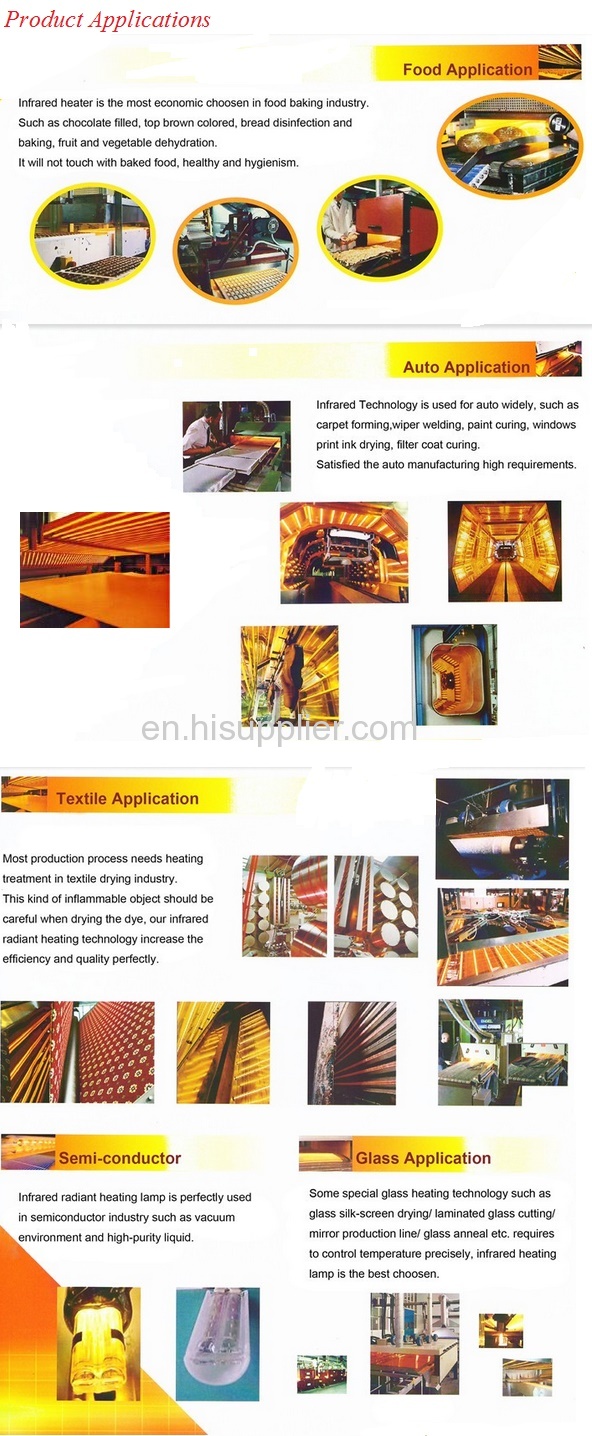

Twin Tube Short Wave Infrared Heater Lamps

This is made up high-purity clear quartz twin tube, each tube has Heating Coil of Tungsten material which runs in U shape in the tube which is filled with halogen gas.This provides a very high energy source capable of responding instantly to voltage changes, allowing for precise temperature control for a variety of applications.

Reflector/Coating Types

Clear Tube without Any Reflector

Gold Coating

White Plating

Product name | Short Wave IR Lamp |

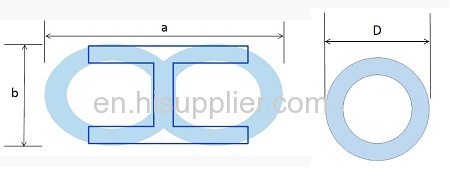

Tube diameter | 8*18mm/11*23mm/15*33mm |

Total length/Heated length | 420mm/350mm |

Power/Voltage | 1000W/380V |

Wavelength range | 0.75-1.4um |

Response Time | 1s |

Electric heat transformation rate | >98%

|

Filament Temp | 2200℃ |

Max Heating Length | 6400/ 2400 mm |

Warranty Time | 1800 ° - 2400 °C

|

High Power Density | up to 200w/cm |

Heating Filament | Tungsten |

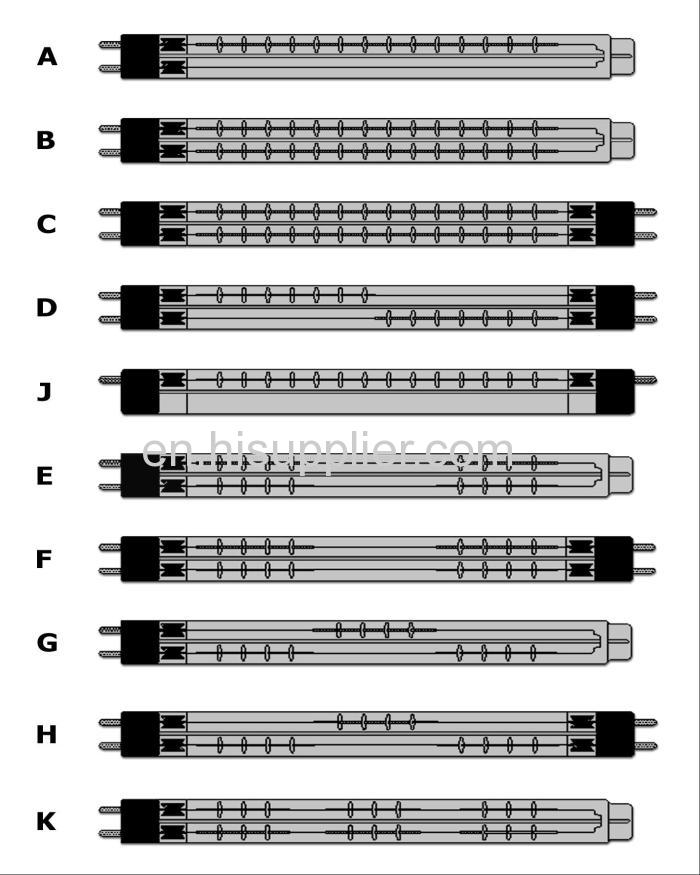

Various Design at filament of Shhort Wave Twin Tubes

Twin tube Product data sheet

Voltage

| Watt | Quartz tube | Total length | Heated length | Construction |

55V | 400W | 11*23mm | 115mm | 50mm | B |

480V | 10000W | 11*23mm | 1860mm | 1780mm | C |

240V | 2000W | 11*23mm | 320mm | 255mm | B |

240V | 1500W | 11*23mm | 225mm | 190mm | B |

115V | 450W | 11*23mm | 70mm | 25mm | B |

480V | 6000W | 11*23mm | 1120mm | 1000mm | C |

120V | 800W | 11*23mm | 167mm | 102mm | B |

115V | 900W | 11*23mm | 170mm | 115mm | B |

240V | 1500W | 11*23mm | 260mm | 216mm | B |

400V | 5400W | 11*23mm | 1200mm | 1100mm | H |

415V | 3500W | 11*23mm | 1100mm | 1020mm | A |

400V | 3500W | 11*23mm | 850 | 760mm | B |

400V | 5000W | 11*23mm | 1550mm | 1440mm | B |

240V | 2750W | 11*23mm | 450mm | 350mm | B |

480V | 5510W | 11*23mm | 800mm | 700mm | B |

240V | 1250W | 11*23mm | 250mm | 190mm | B |

230V | 2350W | 11*23mm | 410mm | 355mm | B |

115V | 400W | 11*23mm | 115mm | 50mm | B |

Advantages

Quartz glass infrared emitter frequently prove superior to conventional heating sources such as warm air,steam,ceramic,gas or metal emitters,because they transfer large amounts of energy very quickly and can be precisely matched to the product and the manufacturing step -the ideal heating process.

-Infrared radiation requires neither contact nor intermediate transfer medium

-Quartz glass infrared emitters are precisely matched to the materials to be heated

-Fast response times allow controllable heat

-Heat is applied precisely where and only for so long as it is required

Compared for example to warm air heating ,this often means less energy consumption,higher line speed,a smaller footprint and better result .

About Our Company

Hefei Quickly Electric Co.,ltd is a manufacturer of high quality Quartz electric heating elements. We proudly manufacture every elements we sell. Every element is manufactured from high quality materials sourced from both domestic and foreign suppliers. We make the finest quality elements in the market.

Drying oven for coating/reflector on quartz tube

RFQ

1.Why Quartz Glass as the one main of material?

The choice of quartz glass is not a coincidence: this extraordinary material is totally transparent at IR radiation, can withstand constant working temperatures of more than 1000°C and it is resistant to chemical corrosion.

2.Typs of Quartz tubes

Quartz uses two kinds of quartz tubes: single tube and twin tube. The twin tube provides the best mechanical resistance, thanks to its reverse "H" shape, and it allows to manufacture emitters up to 6,5 meters in length.

3.Why Reflector

All of our emitters can be coated with a layer of gold or ceramic as reflectors. The gold/ ceramic coating can concentrate the heat, increasing the effectiveness of the heat output.

The emitters with coating are highly economical, converting practically all the consumed electrical power into heat

For the emitters with high watt density or the surface temperature of the tube above 800°C , we suggest to use ceramic coating as reflector because the temperature resistance is up to 1000°C

In addition to 180° (half-tube) coating, we also manufacture 270° coating or other customer specified degrees.

4.The lamp can be used in vertical Orientation?

Yes, it can be used in vertical basides in horizontal position,see as the below picture

The first step in designing or purchasing a Quartz element is determining if it is mounted in a horizontal or vertical position. Typically, Quartz elements are mounted in a horizontal position. This is the simplest design. However, some applications require the element to be in a vertical position. The only difference that makes in the design of the element is that the element coil cannot be stretched; it must be tightly wound such that it can support itself in a vertical position. This requires additional processing on the coil to form an insulating coating on the wire so there is no electrical contact between the turns of the coil. Vertical or Close Wound coils are not a problem for us. We can make these in any length, but due to the more stringent physical specifications of the coils, some designs may not be possible. Note: A minimum purchase is required for these elements due to the extra processing required.

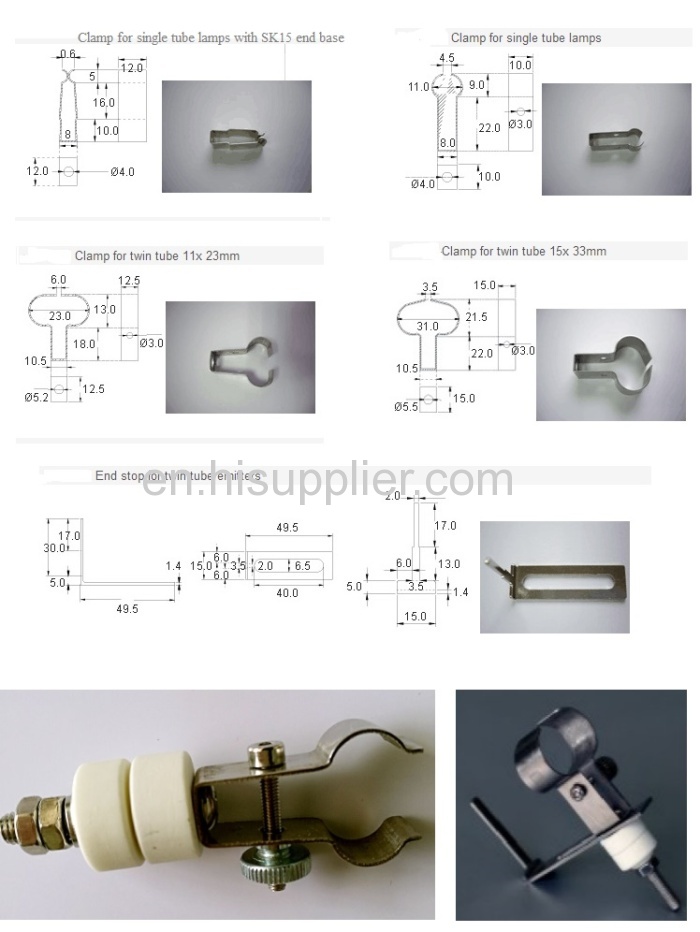

5.could you supply clamps for lamp installing ?

Yes, we will provide mounting clamps for clients, and the corresponding clamps quantity with purchased lamps are supplied freely bu us.

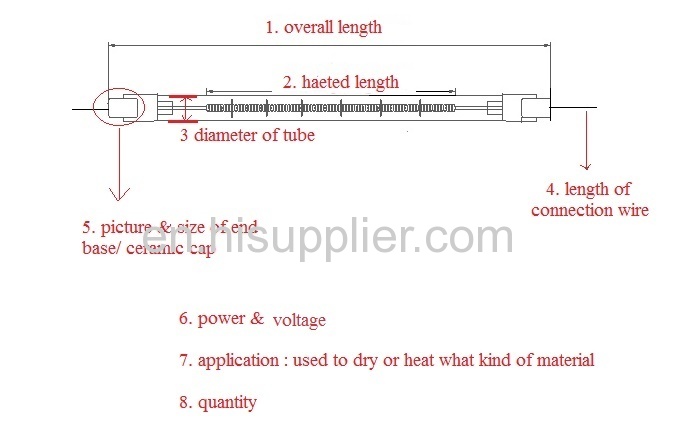

6. What information i need to confirm before sending inquiry

Input Voltage, Wattage, Overall Length ( including ceramic base), Heated Length, Tube Diameter, Reflector Type, Lead wire (length);

If this is a new project, show me information such as : what material the lamps will be used to drying or heating , oven size, required working temperature, limited time, speed, voltage...

7. How does your factory do quality control

7. How does your factory do quality control

" quality is priority", we always and keep paying more attention to QC from the material purchasing to the lamps' packing. Our product have gained CE, ROHS, ISO9001.

8. How you do lamps package?

9. How To make the shipping and payment?