L shaped quartz halogen infrared heater lamps for solar cell printing oven

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 10000 pieces per month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | KKLT206 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Material: | Others |

| Certification: | CE |

| Specification: | Others |

| Color: | Others |

| Brand Name: | QUICKLY |

| Brand: | QUICKLY |

| Type: | Infrared Heater Lamps |

| Origin: | China |

| Certificate: | CE,ROHS, ISO9001 |

| Power: | 500w/1100w/2500w/3500w |

| Voltage: | 90v/120v/220v/230v/240v/380v/440v/ |

| Quartz Tube: | 99.97-99.99% purity |

| Cable Wire: | Teflen / UL textile wire / High Temperature Resistant wire |

| Filament Types: | alloy wire or tungsten |

| Multiple coatings: | Gold, Ceramic and Ruby |

| Production Capacity: | 10000 pieces per month |

| Packing: | EPE and plywooden case |

| Delivery Date: | 5 working days after receving deposit |

Product Description

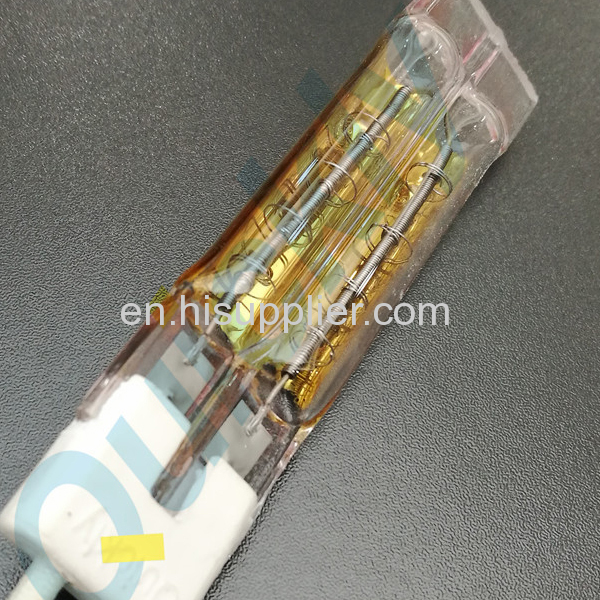

Twin Tube

Available in standard and custom configurations:

Standards:

· Short-Wave: 200 Watts/linear in.

· Fast-Response Medium-Wave: 120 Watts/linear in.

· Carbon-based Medium-Wave: 200 Watts/linear in.

· Meduim-Wave: 50 Watts/linear in.

· Heated Length measured in whole inches

· Voltages: 120VAC, 240VAC, 480VAC

· Available with straight wire leads, quick-disconnect sockets and 90 degree leads

· Multiple coatings available: Gold, Ceramic and Ruby

Twin Tube Short Wave Infrared Heaters

This is made up high-purity clear quartz twin tube, each tube has Heating Coil of Tungsten material which runs in U shape in the tube which is filled with halogen gas.

· Power Density up to 20KW/m2 is achieved. Heating up and cooling down time is approximately one second

· These heaters are available with gold reflector and without reflector

· Reflector is in the form of gold/ceramic white coating on outer rear side of the tube

· Due to reflector heat loss from backside is prevented and thus power saving is achieved

· This also results in making surrounding work area cooler

· This also increases the efficiency and directionality of the heater

· There are two standard sizes 11 mm x 23 mm and 15 mm x 33 mm in cross section. Maximum length available is 4600mm

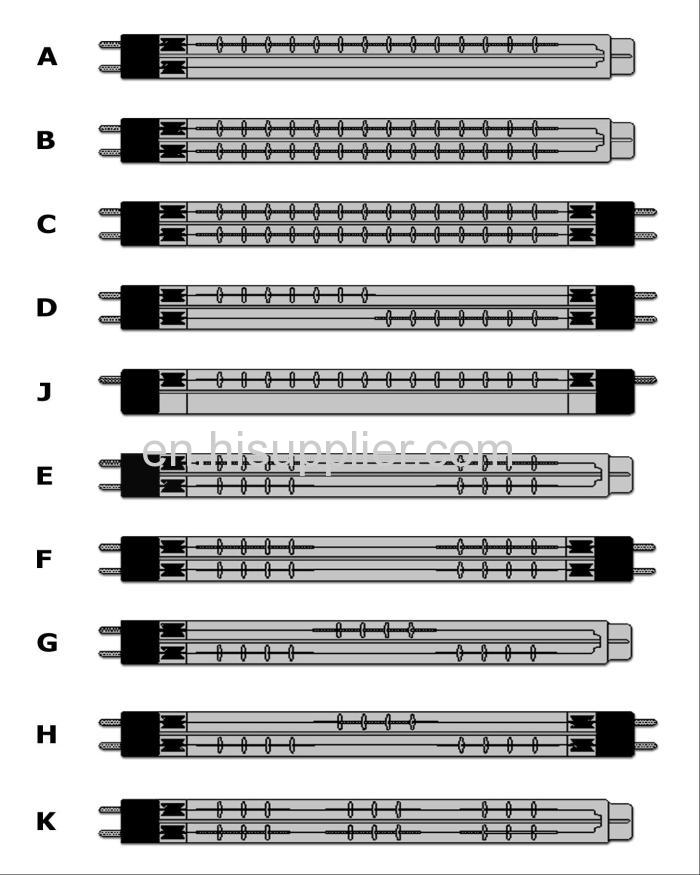

Various Designs Of Filament

Twin Tube Medium Wave Infrared Heater

· Operating temperature 900° C

· Using Ni-Cr or Fe-Cr-A1 resistance wire as filaments

· Response time around 1 minute

· IR wavelength between 2-4 M

· Average working life up to 20000 hours

· Gold or ceramic coating at rear side as a reflectors

· Dimensions 11 x 23mm and 15 x 33mm

· Max. overall length up to 6000mm

Various Designs Of Filament

Twin Tube IR Lamps Specifications List

The IR Heater Range | Format | Heated Length | Total Length | Max. Output | |

Short Wave IR Heater | Halogen NIR | 10/11/12 dia. | 60-1000 | 110-1100 | 9000 |

Single-tube IR | 13/15dia. | 60-1200/1400 | 110-1300/1500 | 7500 | |

Twin-tube IR | 23x11 | 80-3000 | 200-3150 | 14,000 | |

Twin-tube IR | 33x15 | 80-3800 | 200-4050 | 16,000 | |

Medium Wave IR Heater | Single tube | 15/18dia | 80-1400/1700 | 150-1500/1800 | 6,750 |

Twin-tube IR | 18x8 | 80-1500 | 100-1600 | 2500 | |

Twin-tube IR | 23x11 | 100-2000 | 120-2200 | 4500 | |

Twin-tube IR | 33x15 | 500-5800 | 350-6000 | 12,000 | |

Carbon IR Heater | Round tube | 12/15/18 dia. | 120-1000/1680 | 130-1200/1750 | 7,200 |

Twin-tube IR | 23x11 | 80-2500 | 200-2650 | 8,000 | |

Twin tube | 33 x 15 | 120-3000 | 130-3130 | 10,500 | |

Fast Medium wave IR Heater | Single tube | 13/15dia. | 60-1200/1400 | 110-1300/1500 | 6,200 |

Twin-tube IR | 33x15 | 400-3000 | 600-3150 | 12,000 | |

FEATURES & BENEFITS of IR Heater Lamps

· Highly Efficient Heat Source

Over 85% of the input energy is converted into infrared energy.

· Ease of Control

As opposed to combustion heat energy, our light source based energy is easier to control and manipulate by use of lenses and reflectors.

· Compact and Clean Energy

A non-polluting heat source from a light weight and compact footprint enables flexible design possibilities.

· Instant On/Off

Due to the ability to reach maximum output upon ignition, a sophisticated heating programming can be applied.

· Long Life and Consistent Output

By utilizing the halogen cycle, QUICKLY's lamps are designed up to 5000 hrs with almost no loss in infrared output.

· Flexible Production Capability

QUICKLY supports customer specified custom design and OEM support.

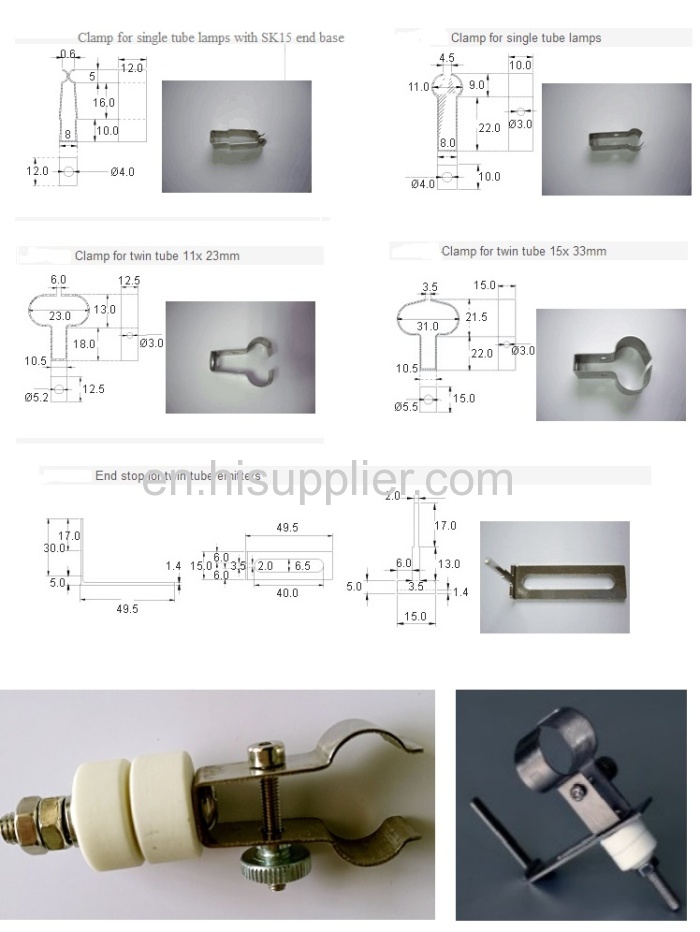

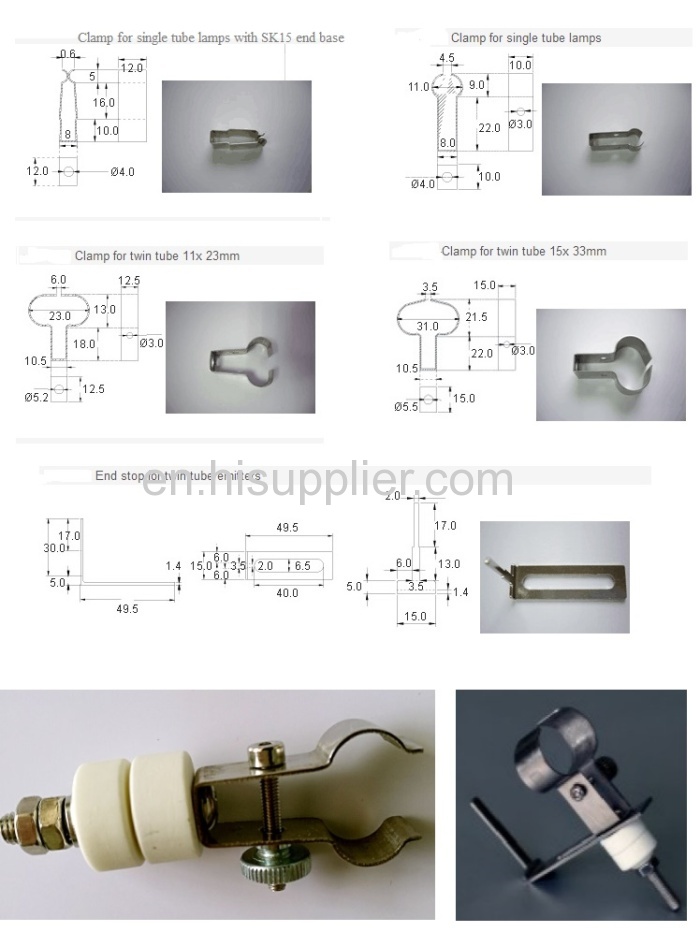

Mounting Clamps for Infrared Heaters

Spectral Radiation Curves and Wavelength

Infrared heaters are commonly used in infrared modules (or emitter banks) combining several heaters to achieve larger heated areas.

Infrared heaters are usually classified by the wavelength they emit:

Near infrared (NIR) or short-wave infrared heaters operate at high filament temperatures above 1800 °C and when arranged in a field reach high power densities of some hundreds of kW/m2. Their peak wavelength is well below the absorption spectrum for water, making them unsuitable for many drying applications. They are well suited for heating of silica where a deep penetration is needed.

Medium-wave and carbon (CIR) infrared heaters operate at filament temperatures of around 1000 °C. They reach maximum power densities of up to 60 kW/m2 (medium-wave) and 150 kW/m2 (CIR).

Efficiency

Electrically-heated infrared heaters radiate up to 86% of their input as radiant energy.Nearly all the electrical energy input is converted into infrared radiant heat in the filament and directed onto the produce by reflectors. Some heat energy is removed from the heating element by conduction or convection, which may be no loss at all for some designs where all of the electrical energy is desired in the heated space, or may be considered a loss, in situations where only the radiative heat transfer is desired or productive.

For practical applications, the efficiency of the infrared heater depends on matching the emitted wavelength and the absorption spectrum of the material to be heated. For example, the absorption spectrum for water has its peak at around 3000 nm. This means that emission from medium-wave or carbon infrared heaters is much better absorbed by water and water-based coatings than NIR or short-wave infrared radiation. The same is true for many plastics like PVC or polyethylene. Their peak absorption is around 3500 nm. On the other hand, some metals absorb only in the short-wave range and show a strong reflectivity in the medium and far infrared. This makes a careful selection of the right infrared heater type important for energy efficiency in the heating process.

Our Service

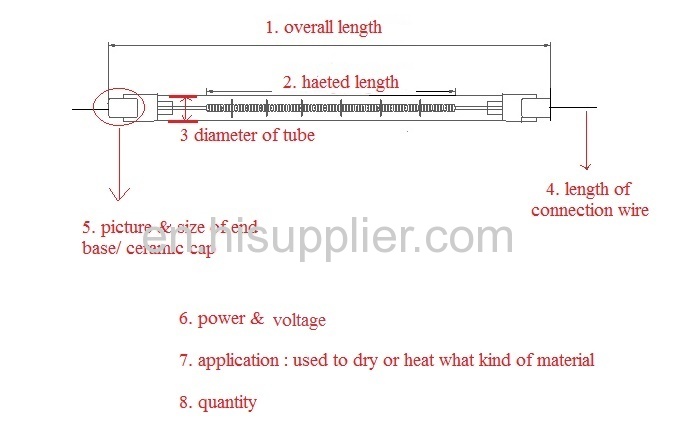

Custom designs

Elements can be designed to your specifications.

Need prototypes or samples?

We'll be glad to provide them for you and in some cases for free.

Do you have special end requirements?

We can accommodate your needs,in this case, we will have a requirement of min order quantity 100pcs at least.

Have an unusual design?

Send us a drawing, sketch, or sample and we'll be happy to quote it.

We specialize in small runs and custom designs, but can be highly competitive on large orders as well.

Engineering consulting

Not sure if quartz is right for your application? Contact me and we'll help you make the right choice. We can also assist you in picking the right infrared characteristics for your specific application. Please note, there are thousands of possible applications for quartz infrared tubes and numerous factors affecting which design works best. There is a limit to what we can help with, but we will try our hardest!

About Our Company

Hefei Quickly Electric Co.,ltd is a manufacturer of high quality Quartz electric heating elements. We proudly manufacture every elements we sell. Every element is manufactured from high quality materials sourced from both domestic and foreign suppliers. We make the finest quality elements in the market.

FAQ

1.Why Quartz Glass as the one main of material?

The choice of quartz glass is not a coincidence: this extraordinary material is totally transparent at IR radiation, can withstand constant working temperatures of more than 1000°C and it is resistant to chemical corrosion.

2.Typs of Quartz tubes

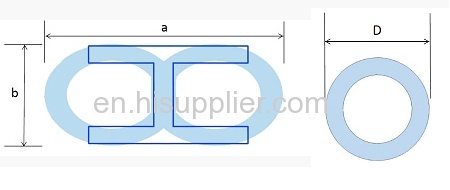

Quartz uses two kinds of quartz tubes: single tube and twin tube. The twin tube provides the best mechanical resistance, thanks to its reverse "H" shape, and it allows to manufacture emitters up to 6,5 meters in length.

3.Why Reflector

Industrial infrared heaters sometimes use a gold/white/ruby coating on the quartz tube that reflects the infrared radiation and directs it towards the product to be heated. Consequently, the infrared radiation impinging on the product is virtually doubled. Gold is used because of its oxidation resistance and very high IR reflectivity of approximately 95%

4.could you supply clamps for lamp installing ?

Yes, we will provide mounting clamps for clients, and the corresponding clamps quantity with purchased lamps are supplied freely bu us.

5.Have an unusual design?

Send us a drawing, sketch, or sample and we'll be happy to quote it.

We specialize in small runs and custom designs, but can be highly competitive on large orders as well.

6.How does your factory do quality control

" quality is priority", we always and keep paying more attention to QC from the material purchasing to the lamps' packing. Our product have gained CE, ROHS, ISO9001.

7. How you pack the lamps ?

8. How To make the shipping and payment?