535 high temperature firing furnace IR emitter

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 10000 pieces per month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SWIR-10535 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Material: | Others |

| Certification: | CE |

| Specification: | Others |

| Color: | Yellow |

| Brand Name: | QUICKLY |

| Brand: | QUICKLY |

| Type: | Short Wave Infrared Heater Lamps |

| Warranty Time: | 5000 Hours |

| Certificate: | CE,ROHS, ISO9001 |

| Power: | 300-10000w |

| Voltage: | 80-600v |

| Quartz Tube: | 99.97-99.99% purity |

| Cable Wire: | Teflen / UL textile wire / High Temperature Resistant wire |

| Filament Temperature: | 1800℃-2200℃ |

| Color: | golden |

| Production Capacity: | 10000 pieces per month |

| Packing: | EPE and plywooden case |

| Delivery Date: | 5 working days after receving deposit |

Product Description

535 high temperature firing furnace IR emitter

535 high temperature firing furnace IR emitter Specifications List

1 | Quartz Tube Cross Section | 23*11mm (customized) |

2 | Peak Wavelength | 0.75-1.4um |

3 | Total Length. | 320mm(customized) |

4 | Heated Length | 255mm(customized) |

5 | Power | 2000w(customized) |

6 | Voltage | 240v(customized) |

7 | Standard Lead Wire Length | 300mm (customized) |

8 | Response Time | 1-2s |

9 | Warranty Time | 5000 Hours (24Hs/Day) |

10 | Color | Golden(customized) |

11 | Filament | Tungsten |

12 | Installing Orientation | Horizontal |

535 high temperature firing furnace IR emitter

Twin tube Construntion Type:

Type A: One side connection, one channel heating, another not heating, only one side with ceramic base;

Type B: One side connection, both two channels heating, only one side with cearmic base;

Type C: Two sides connection, both two channels heating, both two sides with ceramic base;

Type D: Two sides connection, both two channels heating, Up channel heating on the left, down channel

heating on the right, both two sides with ceramic base;

Type E: One side connection, both two channels heating but not constantly heating, both two channels

heating on two sides with a part in the middle not heating, only one side with ceramic base;

Type F: Two sides connection, both two channels heating but not constantly heating, both two channels

heating on two sides with a part in the middle not heating, both two sides with ceramic base;

Type G: One side connection, both two channels heating but up channel heating in the middle but down

channel heating on the two sides with the middle part not heating, only one side with ceramic base

Type H: Two sides connection, both two channels heating but also not constantly heating, up channel

heating in the middle and down channel heating on the two sides with middle part not heating, both

two sides with ceramic base;

Type K: One side connection, both two channels heating, but with three parts of not constantly heating

wire in both two channels, only one side with ceramic base.

Comparasions of Short wave IR, Fast Medium wave IR, Carbon IR and Medium wave IR:

535 high temperature firing furnace IR emitter

Quickly Infrared heating product range

The IR Heater Range | Format | Heated Length | Total Length | Max. Output | |

Short Wave IR | Halogen NIR | 10/11/12 dia. | 60-1000 | 110-1100 | 9000 |

Single-tube IR | 13/15dia. | 60-1200/1400 | 110-1300/1500 | 7500 | |

Twin-tube IR | 23x11 | 80-3000 | 200-3150 | 14,000 | |

Twin-tube IR | 33x15 | 80-3800 | 200-4050 | 16,000 | |

Carbon IR | Round tube | 12/15/18 dia. | 120-1000/1680 | 130-1200/1750 | 7,200 |

Twin-tube IR | 23x11 | 80-2500 | 200-2650 | 8,000 | |

Twin tube | 33 x 15 | 120-3000 | 130-3130 | 10,500 | |

Fast Medium wave IR | Single tube | 13/15dia. | 60-1200/1400 | 110-1300/1500 | 6,200 |

Twin-tube IR | 33x15 | 400-3000 | 600-3150 | 12,000 | |

Medium Wave IR | Single tube | 15/18dia | 80-1400/1700 | 150-1500/1800 | 6,750 |

Twin-tube IR | 18x8 | 80-1500 | 100-1600 | 2500 | |

Twin-tube IR | 23x11 | 100-2000 | 120-2200 | 4500 | |

Twin-tube IR | 33x15 | 500-5800 | 350-6000 | 12,000 | |

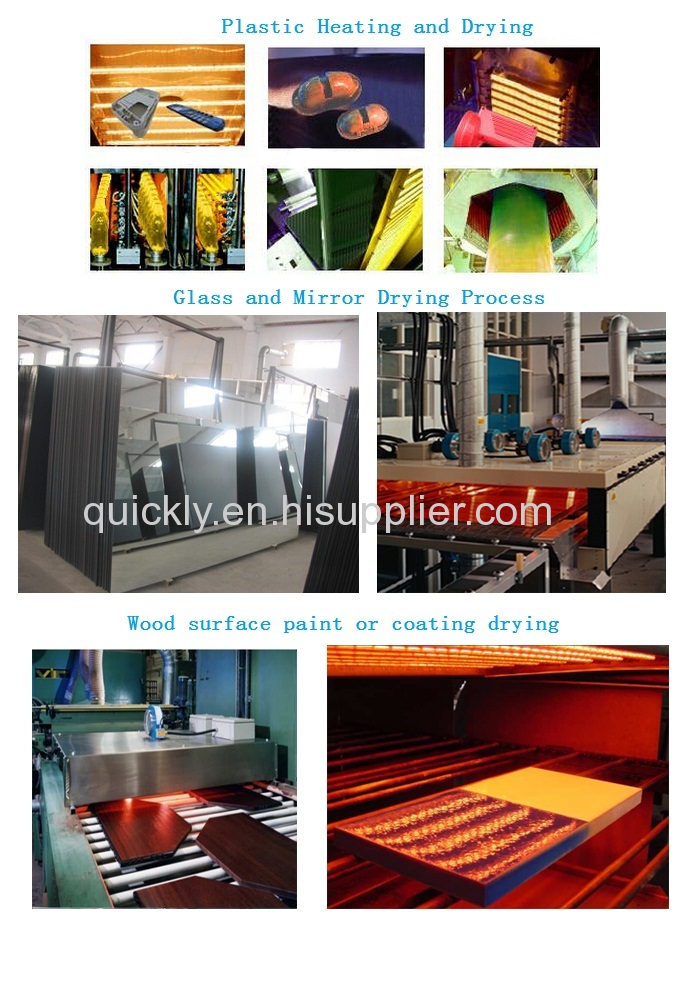

Application of 535 high temperature firing furnace IR emitter

INDUSTRY MACHINERY:

Infrared drying oven for aluminum mirror painting, Car paint curing, PCB printing drying process,

Solar cell firing furnace Solar PV Module string welding machine, Electronics panel preheating IR

panel, Conveyor zone IR tunnel, Wood industry surface paint drying, Semi-conductor infrared

drying oven, Textile printing drying system, Plastic floor heating module, Plastic bucket heating

system, Electric infrared curing systems large, Clam shell oven

Some application pictures:

Production work shop:

Packing and Delivery

Comapny and Location:

Company Name: Hefei Quickly Electric Co., Ltd.

Company address: Jiahai Industrial Zone C-34, Xinbengbu Road,

Xinzhan District, Hefei, China

Who you can find to answer your questions and offer you a solution?

Contact sales person: Ares Qian

Technical support: quickly2(at)ir-heater.com/ aries0907(at) outlook.com

Skype: aries.qian

Whatsapp: 86_18605655617

535 high temperature firing furnace IR emitter

Quickly infrared heating development history:

Since 1999, the infrared heating has been spread to the whole world, Quickly leaders notice

that it will be a heating method which can replace most of the heating method in the current

situation, such as the stainless heaters, panel heating elements, heating resistance, hot oil

heating method, gas heating, convention heating, and so on.

After we start the first type of infrared heating element-the medium wave heaters production

and then we gain a good reputation in the glass industry, then we start the shortwave IR

heaters lamp's production, and the carbon infrared heater, now we develop many other

industries to exchange their traditional heaters or original supplier, help to improve them

20% energy.

With more customers' trusting and co-efforts, we now build several production line with a

secure QC process.

As for the technical improvement, now we achieve to make a shortwave heater with

100-140W/cm power density for the single tube, and it also have a lifetime of 1000 hours.

As for the maximum length of the medium wave infrared heaters, we now can make 6000mm

long for the 33*15 twin tube type.

With years' development and study, we now have more accurate data for the wavelength for

the shortwave, medium wave and carbon medium wave IR heaters.

And we believe we will do better as so many customers trust in us and help us to get progresses

together. Quickly will have a more strong service team for the world's infrared heating.