transparent quartz tube heater part

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 10000 pieces per month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SWIRS025 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Material: | Others |

| Certification: | CE |

| Specification: | Others |

| Color: | Others |

| Brand Name: | QUICKLY |

| Brand: | QUICKLY |

| Type: | Short Wave Infrared Heater Lamps |

| Warranty Time: | 5000 Hours |

| Certificate: | CE,ROHS, ISO9001 |

| Power: | 500w/1100w/2500w/3500w |

| Voltage: | 90v/120v/220v/230v/240v/380v/440v/ |

| Quartz Tube: | 99.97-99.99% purity |

| Cable Wire: | Teflen / UL textile wire / High Temperature Resistant wire |

| Filament Temperature: | 1800℃-2200℃ |

| Color: | clear/gold/white |

| Production Capacity: | 10000 pieces per month |

| Packing: | EPE and plywooden case |

| Delivery Date: | 5 working days after receving deposit |

Product Description

Short Wave Infrared Heater Lamps

Clear Tube IR Lamp

Gold Coating IR Lamp

White plated IR Lamp

Short-wave infrared emitters utilize a low-mass tungsten filament that is incased in a special blend of inert gasses. This provides a very high energy source capable of responding instantly to voltage changes, allowing for precise temperature control for a variety of applications.

· Glass Tube:99.9% Pure Fused Silica Quartz Sealed

· Filament Material:Tungsten

· Filament Temperature:1800 - 2400C℃(3300 - 4400F)

· Peak Wavelength:1.0 - 1.4 Um

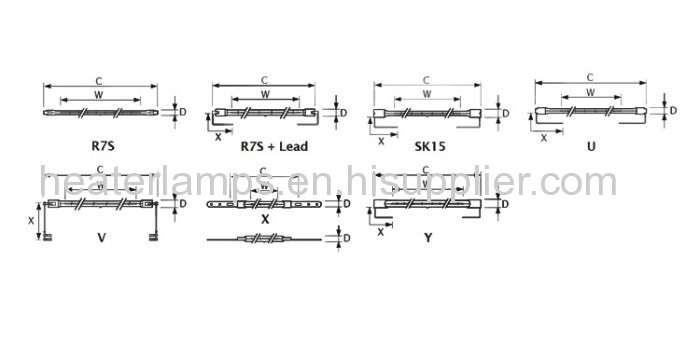

Construction Types

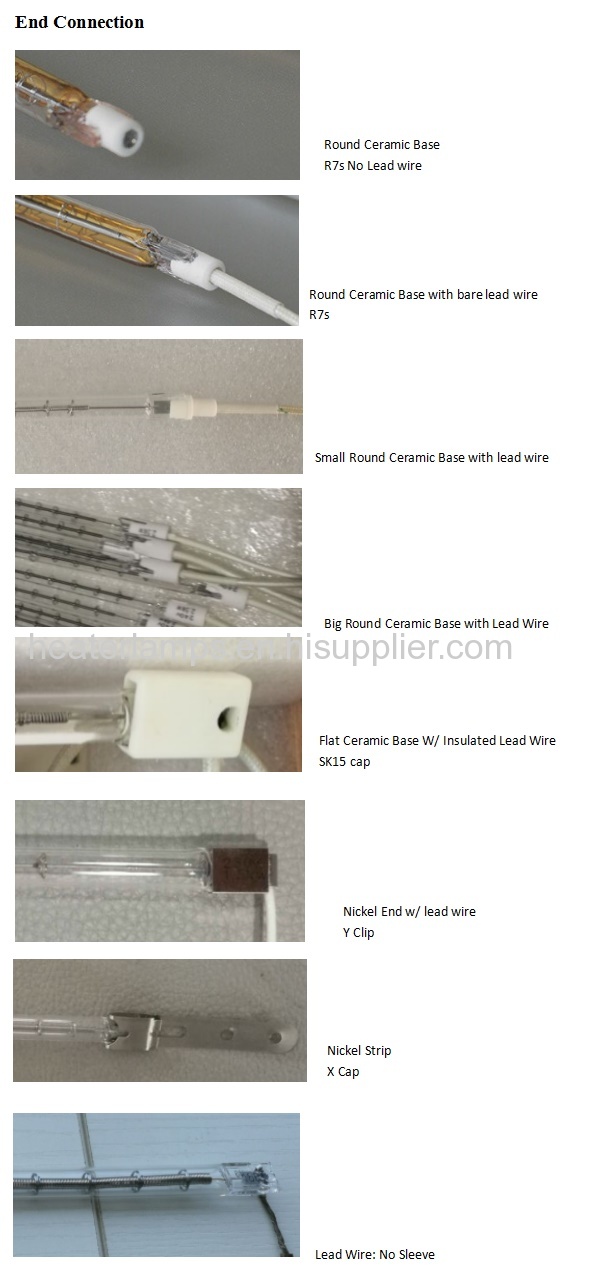

Ceramic Base Types

Details about Short Wave IR Heater Lamps

Description

Hefei Quickly Electric Co.,LTD specifies tungsten filament Infrared halogen lamps in most of its heaters. The Halogen Cycle increases the life of the lamp. Halogen gas is added to the inert gas in the lamp. As the heater operates, tungsten slowly evaporates from the filament and combines with the halogen to create a tungsten halide. As the tungsten halide touches the filament, the heat separates the halide into tungsten and halogen gas and re-deposits the tungsten back on the filament. The freed halogen gas then repeats the process.

Rapid Response

The lamps heat up and cool down instantly in response to changes in applied voltage. They radiate 90 percent of the available radiant energy in less than one second after being turned on. By comparison, long wave length infrared emitters must be energized for several minutes before they reach the same relative output. Similarly, the short-wavelength infrared emitter in the lamps cools down much faster than a long wave length infrared emitter. This is in part due to the greater thermal mass of long wave length emitters.

Tungsten Wire Filament

The high-density infrared energy is produced by a tungsten wire filament in the lamp. The filament is supported by tungsten wire ring anchors, tantalum disks, or through deflection winding of the filament to create the support from the filament itself. The supports prevent the filament from coming into contact with the quartz lamp envelope and causing the lamp to fail.

Atmosphere

The inert atmosphere in the quartz glass envelope protects the tungsten wire filament from oxidation.

Electrical Connections

In most cases, connections to supply electricity to the tungsten wire filament are made through flexible pigtail leads. Button contacts and screw bases are also used on some lamps to make this connection. Lamps with end leads should be installed so the leads have a small amount of slack to allow for thermal expansion during operation. This will eliminate lamp failure caused by rigid leads transferring this expansion to the quartz glass envelope

Reflector

The gold/ ceramic coating can concentrate the heat, increasing the effectiveness of the heat output.

The emitters with coating are highly economical, converting practically all the consumed electrical power into heat.

For the emitters with high watt density or the surface temperature of the tube above 800°C , we suggest to use ceramic coating as reflector because the temperature resistance is up to 1000°C .

In addition to 180° (half-tube) coating, we also manufacture 270° coating or other customer specified degrees.

Advantages

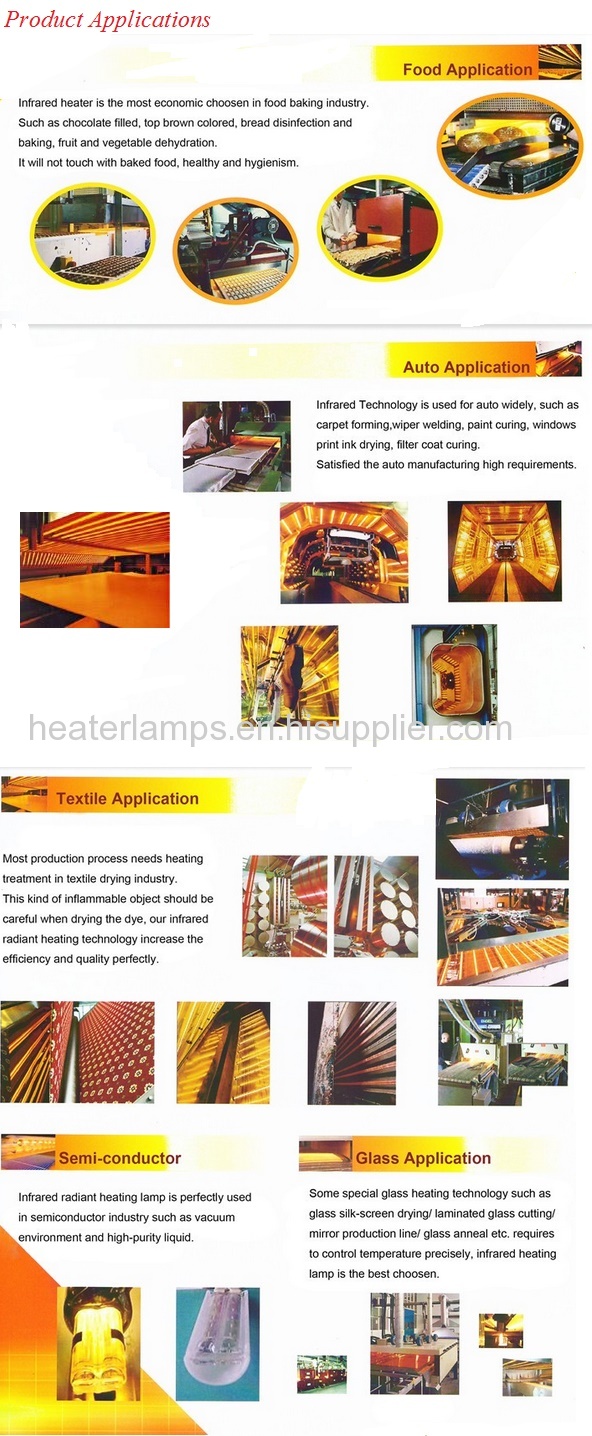

Quartz glass infrared emitter frequently prove superior to conventional heating sources such as warm air,steam,ceramic,gas or metal emitters,because they transfer large amounts of energy very quickly and can be precisely matched to the product and the manufacturing step -the ideal heating process.

-Infrared radiation requires neither contact nor intermediate transfer medium

-Quartz glass infrared emitters are precisely matched to the materials to be heated

-Fast response times allow controllable heat

-Heat is applied precisely where and only for so long as it is required

Compared for example to warm air heating ,this often means less energy consumption,higher line speed,a smaller footprint and better result .

FAQ

1. What kind of IR lamp you manufacture

Short Wave Infrared Heater Lamps

Medium Wave Infrared Heater Lamps

Carbon Medium Wave Infrared Heater Lamps

Fast Medium Wave Infrared Heater Lamps

All of our product are customized according to your required diameter, length, power,voltage, reflector, shape...

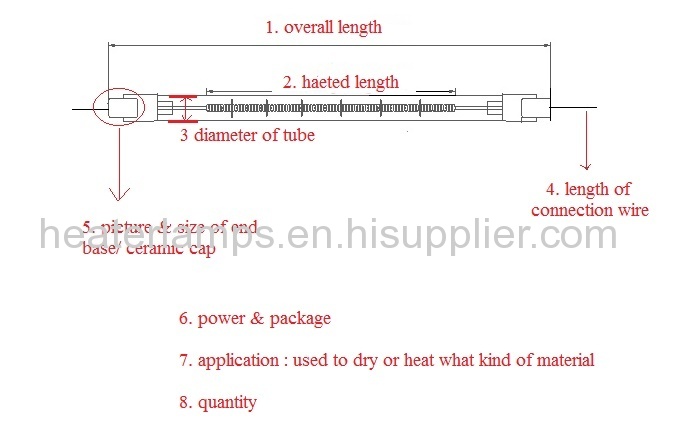

2. What information i need to confirm before sending inquiry

Input Voltage, Wattage, Overall Length ( including ceramic base), Heated Length, Tube Diameter, Reflector Type, Lead wire length, Ceramic base type, Application, Quantity

3. How does your factory do quality control

" quality is priority", we always and keep paying more attention to QC from the material purchasing to the lamps' packing. Our product have gained CE, ROHS, ISO9001.

4.Where is your company located

Our company locates at Hefei City, Anhui Province, China; warmly welcome to visit us

5. How you pack the lamps ?

6. How To make the shipping and payment?