short wave infrared heater lamp for press machine

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 10000 pieces per month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SWIR-TG231000 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Material: | Others |

| Certification: | CE |

| Specification: | Others |

| Color: | Others |

| Brand Name: | QUICKLY |

| Brand: | QUICKLY |

| Type: | Short Wave Infrared Heater Lamps |

| Warranty Time: | 5000 Hours |

| Certificate: | CE,ROHS, ISO9001 |

| Voltage: | 90v/120v/220v/230v/240v/380v/440v/ |

| Power: | 500w/1100w/2500w/3500w |

| Quartz Tube: | 99.97-99.99% purity |

| Cable Wire: | Teflen / UL textile wire / High Temperature Resistant wire |

| Filament Temperature: | 1800℃-2200℃ |

| Color: | clear/gold/white |

| Production Capacity: | 10000 pieces per month |

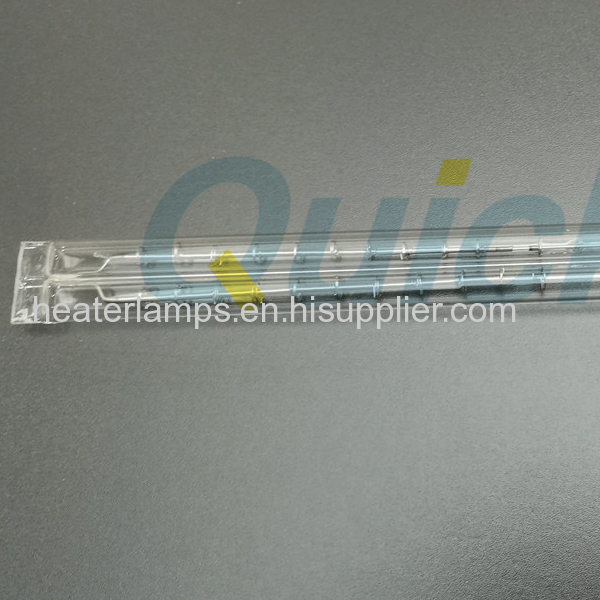

| Packing: | EPE and plywooden case |

| Delivery Date: | 5 working days after receving deposit |

Product Description

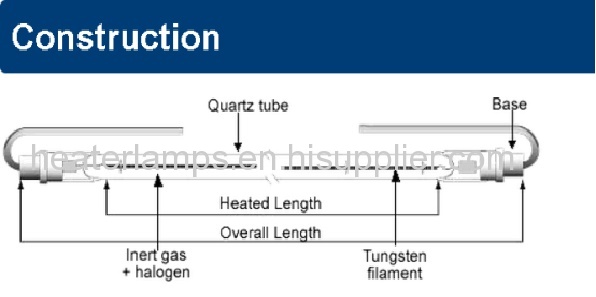

IR Emitters

Infrared (IR) is defined as invisible radiant energy with longer wavelengths than those of visible light. Infrared Emitters (IR) are a source of light energy in the infrared spectrum opposite that of UV. IR Emitters are a source of heat energy and are used in many industries ranging from wood, food and textiles to hundreds of processes in the automotive industries.

Twin Tube IR emitters are two IR emitters fused together as one. They deliver more power to a smaller area, thus creating a more powerful emitter. Additionally, each twin tube emitter utilizes a 180 degree back reflector that is coated directly on the quartz tube envelope. This coating material is a high purity gold substrate. Gold is the most efficient IR reflective material.

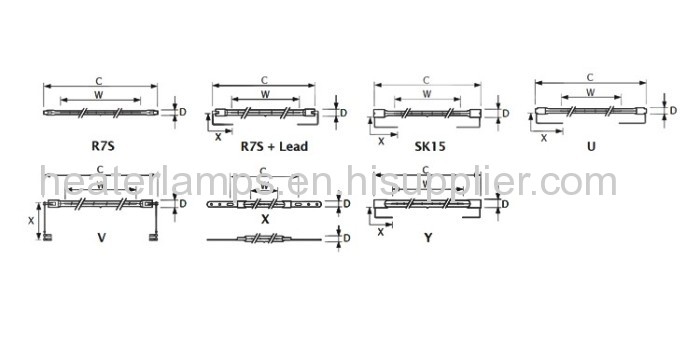

We are more than happy to provide you with a quote. If you are looking for an IR Emitter please give us a call. These are the questions we will need answered in order to provide a quote:

· Watts

· Volts

· Total Length in mm

· Heated Length in mm

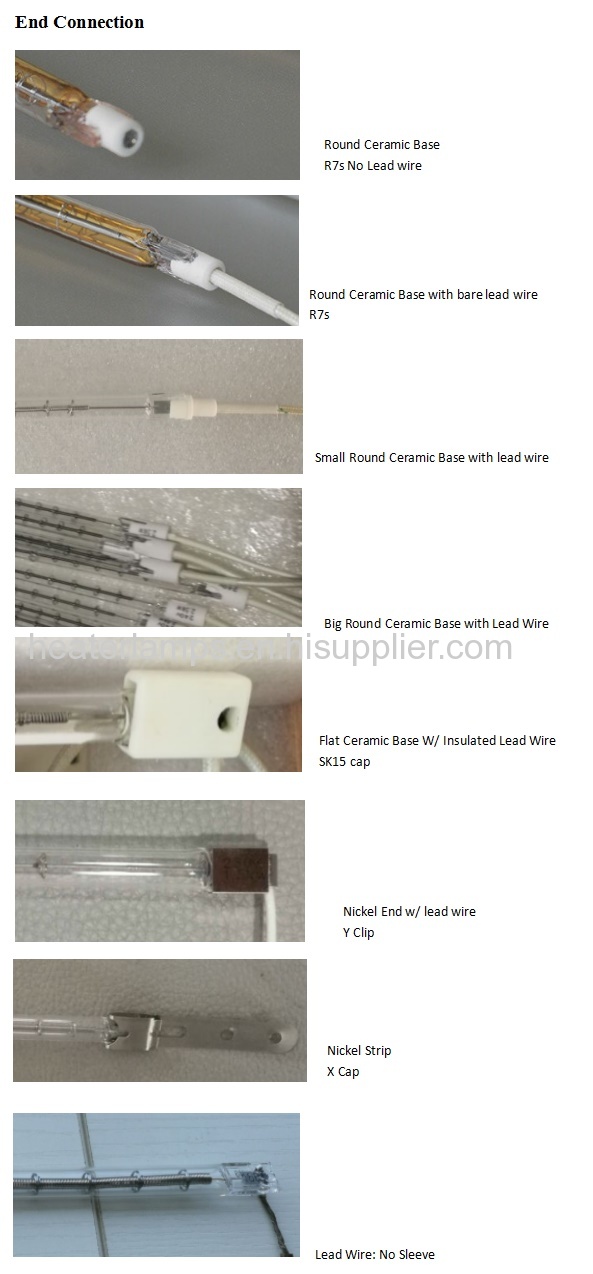

· End Cap style

· Single or Twin tube?

· Quartz Diameter?

· Mounting Vertically or Horizontally?

Single IR emitters

Available in standard and custom configurations:

Standards:

· Short-Wave: 100 Watts/linear in.

· Fast-Response Medium-Wave: 60 Watts/linear in.

· Carbon-based Medium-Wave: 100 Watts/linear in.

· Medium-Wave: 25 Watts/linear in.

· Heated length measured in whole inches

· Voltages: 120VAC, 240VAC, 480VAC

· Available with straight wire leads, quick-disconnects and 90 degree leads

· Multiple coatings available: Gold, Ceramic, Ruby

Twin Tube IR Emitters

Available in standard and custom configurations

Standards:

· Short-Wave: 200 Watts/linear in.

· Fast-Response Medium-Wave: 120 Watts/linear in.

· Carbon-based Medium-Wave: 200 Watts/linear in.

· Meduim-Wave: 50 Watts/linear in.

· Heated Length measured in whole inches

· Voltages: 120VAC, 240VAC, 480VAC

· Available with straight wire leads, quick-disconnect sockets and 90 degree leads

· Multiple coatings available: Gold, Ceramic and Ruby

Short-Wave Infrared Heaters

Short-wave infrared emitters utilize a low-mass tungsten filament that is incased in a special blend of inert gasses. This provides a very high energy source capable of responding instantly to voltage changes, allowing for precise temperature control for a variety of applications.

· Glass Tube:99.9% Pure Fused Silica Quartz Sealed

· Filament Material:Tungsten

· Filament Temperature:1800 - 2400C℃(3300 - 4400F)

· Peak Wavelength:1.0 - 1.4 Um

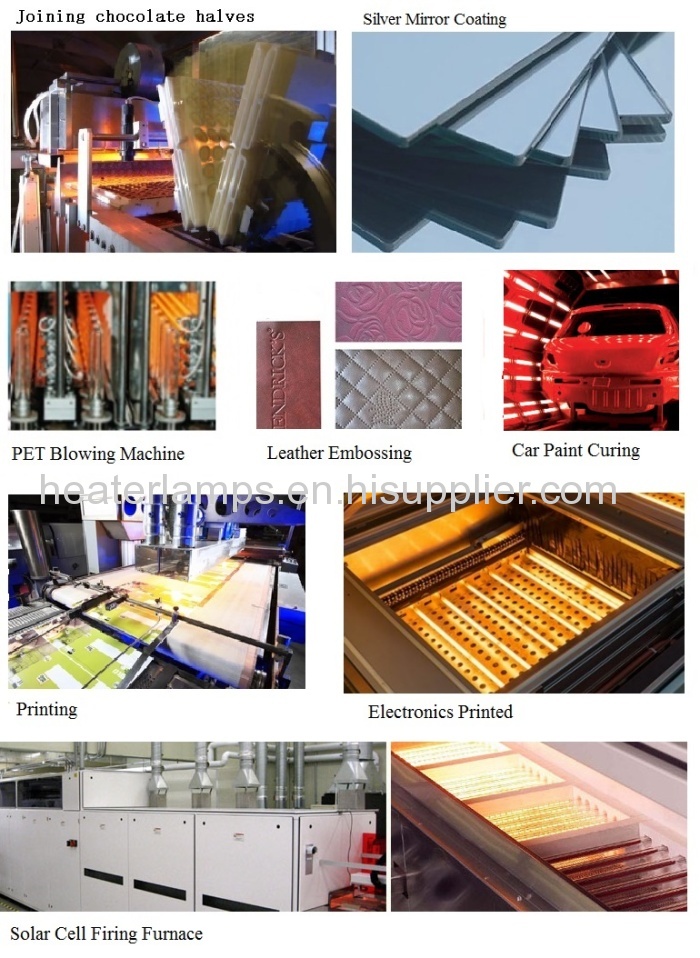

· Typical Applications:

- Plastics Welding

- Curing Painted Surfaces

- Curing Powder Coatings

- Polymerization of coatings for cooking utensils

- Drying porcelain and ceramics

- Drying and production of glass-plastic composites

- Semiconductor Production

Applications of IR Emitters

Shipping & Payment

Company Information

Hefei Quickly Electric Co.,LTD specifies tungsten filament Infrared halogen lamps in most of its heaters. The Halogen Cycle increases the life of the lamp. Halogen gas is added to the inert gas in the lamp. As the heater operates, tungsten slowly evaporates from the filament and combines with the halogen to create a tungsten halide. As the tungsten halide touches the filament, the heat separates the halide into tungsten and halogen gas and re-deposits the tungsten back on the filament. The freed halogen gas then repeats the process.