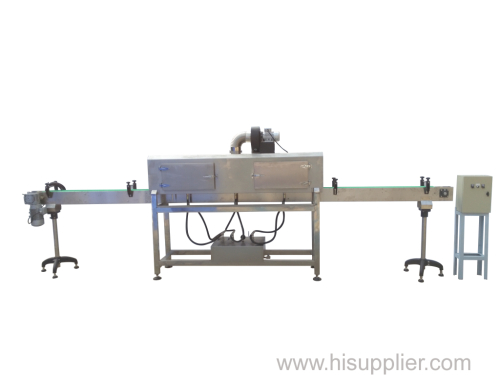

manual shrink labeling machine

| Payment Terms: | L/C, T/T |

|---|---|

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | HF-1500M |

|---|---|

| Means of Transport: | Ocean |

| Processing: | Labeling Machine |

| Automatic Grade: | Automatic |

| Type: | General |

| Usage: | Outer |

| Packaging: | Plastic |

| Brand Name: | howfond |

| material: | 304 stainless steel |

| Packing: | wooden case |

| Delivery Date: | 30days |

Product Description

manual sleeve labeling machine is composed of steam shrink tunnel , and steam generator and conveyor, also called semi auto sleeve labeling machine, it need put bottles onto coneyor manually , and put sleeve labels to bottles manually

1. Brief Introduction

Steam shrink tunnel is used for shrinking sleeve labels to label kinds of bottles: different and irregular round bottles, square bottles, flat bottles and women-shaped bottles. By shrinking PVC or PET sleeve labels to seal bottles caps /necks, cover bottles body even shrink wrap bottle bottom.

To get smooth shrink effect, we usually adjust the heights and positions of the 3 sections of steam spray tubes insides of tunnel. Bottles run on the conveyor, the shrink usually goes from down to top of bottles.

2. Advantage of HF series Steam shrink tunnel.

(1) The blower motor's holder is made of SS304 stainless steel.

(2) The elbow which connects blower motor is made of SS304 steel, no shape changing shape by steam.

(3) The frame is made of SS201 or SS304 stainless steel.

(4) The steam spray tubes are made of SS304 stainless steel.

(5) The steam transmission tubes are made of SS304 stainless steel.

(6) The sizes of entrance/exits suit most bottles.

(7) Available special design and manufacturing for special sizes of bottles.

Item Models | HF-1200M | HF-1500M | HF-2000M | HF-2300M |

Length of tunnel | 1.2meters | 1.5meters | 2.0meters | 2.3meters |

Blower powder | Ø12, 0.25KW | Ø12, 0.25KW | Ø12, 0.25KW | Ø12, 0.25KW |

Powder supply of blower | 220V 3P 60Hz /220V 1P 50Hz | |||

Entrance /exit height | Max 350mm | |||

Entrance /exit width | 130~185mm (fixed size once confirmed) | |||

Running pressure | Max 0.6Mpa | Max 0.6Mpa | Max 0.6Mpa | Max 0.6Mpa |

Weight | 180kg | 200Kg | 220kg | 230kg |

Steam consumption | 18kg/h | 21kg/h | 24kg/h | 24kg/h |

Outline size (m) | L1.2*W0.4*H1.5 | L1.5*W0.4*H1.5 | L2.0*W0.4*H1.5 | L2.3*W0.4*H1.5 |