FRP fiberglass tile construction equipment making machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 100sets/year |

| Place of Origin: | Hebei |

Company Profile

| Location: | Qinhuangdao, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | DN1500-SG |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | dinuo |

| production speed: | 2-12 m/min |

| dimenssion: | 61m*4m*5m |

| staff: | 4-10 people |

| thickness of sheet: | 0.2-4 mm |

| sheet width: | effective width 1500 mm |

| power consumption: | actual consumption is 50KVA/h |

| upper gel coat: | 61m(L)×4(W)×5m(H) |

| lower gel coat: | 71m(L)×1.85(W)×3.5m(H) |

| power requiremen: | 140KVA |

| certification: | EU certification, certified model FRP3200 |

| Production Capacity: | 100sets/year |

| Packing: | customize |

| Delivery Date: | 6 months |

Product Description

This production line can produce lighting sheet, color sheet, common flat sheet, gel coat sheet.

Operation staff | 4-7 People | speed of production | 2-12 m/min |

sheet width | maximum effective width 1500 mm | thickness of sheet | 0.2-4mm |

main dimension | 61m*4m*5m, | power requirement | 140KVA |

power consumption | actual consumption is 50KVA/h | ||

upper gel coat | 61m(L)×4(W)×5m(H) | ||

lower gel coat | 71m(L)×1.85(W)×3.5m(H) | ||

certification | EU certification, certified model FRP3200 | ||

Number of certificate | No.M7, 1302, 8307, 002 | ||

The advantages of our machine

Resin storage system |

the storage tank placed the agitator motor, which can mix the resin with the filler and color paste to reduce the cost of the production. |

Metering system |

1.Pulse-free metering system achieve the precise metering and permitted add powder fillers, that can reduce the cost of production. 2.The pulse-free metering pumps can real-time control the dosage of raw material, for different raw material we applied different pump. For example, for resin, we adopt the CAM rotor pump; for curing agent and accelerator we applied the plunger pump. The practice proved these types of pump not only assure the quality of products, but also good operation. 3. PLC intelligent control system realized every metering pump automatic match the ratio, no need set the proportion one by one. |

Impregnation system |

multi-line independent temperature control, able to better adapt change of ambient temperature, quick impregnation, effectively improve the speed of production. |

Sheet thickness control system |

1.In this area have hard and soft sheet thickness rollers, can achieve precise control thickness of the sheet. These two rollers have different function, if you add the filler to the production, you should use the soft roller. Because the hard roller can't allow the impurity pass through the film, easy to scratch the film. |

Cabinet heating system. |

1,In heating oven system applied the PID control system can accurately adjust the temperature of chambers according to the ambient temperature. For example, If the temperature reached in 40 degree, it is not necessary to put on the heater of the third chamber, that greatly reduced the energy consumption. To reduce the energy, the heating ovens are often alternate work. 2.Meanwhile the heating cabinet can open from the side and upper doors. Many factories produce the chamber with upper side open, which will lose a lot of energy and because of big weight of door, it is difficult to open to change the mold or observe the effect of the sheet. 3. In chamber placed the reversible mold frame, that can realize continuous production. |

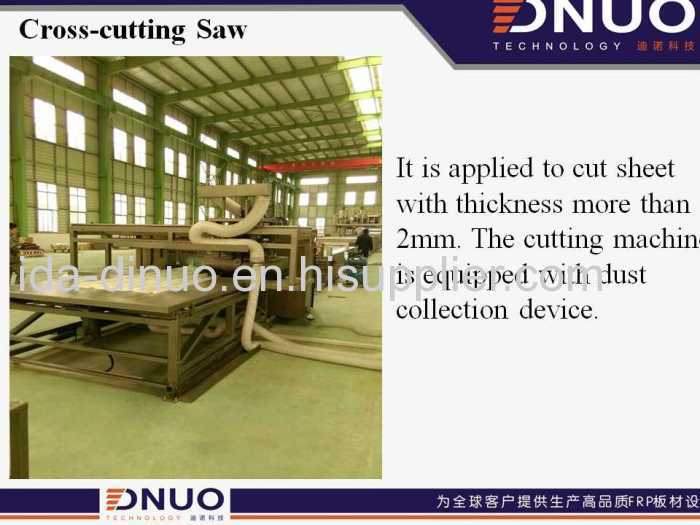

cooling and cutting system |

1. we adopt the free waste edge cutting technology. It means in production we don't need cut the edge of the sheet. The advantages is greatly saving the raw material and reducing the pollution. Meanwhile, expand the space of the workshop and reduce the personal cost. 2. Special cross cutting machine can synchronize with production. Many factories can't realize the synchronous production, because their cutting machine is static, can't moving with the sheet. So often met the problem of off tracking 3. in air-cooling zone, our high-power fan can rapidly cooling the sheet. If the aging process is not handled properly, there will be many problems, such as secondary curing, foaming and yellowish. |

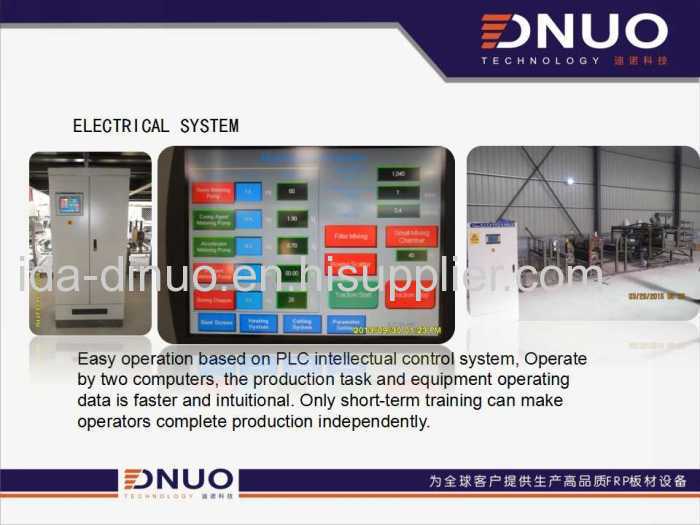

Electric control system |

1. In electric control system, PLC intellectual control system as brain of production line. Operate by computers, the production task and equipment operating data is faster and intuitional. Only short-term training can make operators complete production independently. 2. For different market, we adopt different brand, because some brands is difficult to buy in many countries. In common we choose DELTA, AB, Siemens and so on. On the one hand, it can ensure the equipment running stable, on the other hand it avoid the problem, that because of changing the model or brand, the element is not match with the original machine. 3. Many companies said they configure lots of elements, rather more than our machine. But in fact, to avoid the function confusion and personnel safety issues caused by distribution of cables, we placed all electrical elements into the electrical cabinet to ensure the normal operation and clean of the workhouse. |

Wire and Cable |

Particular parts adopt special purpose wire, durable in use. For example, in cutting system, because of high frequency of using of cutting machine, the cable is often broken. Now we apply integrated folding cable to increase the using life. |

Size and layout of machine |

Size and layout of machine can be made according to customer requirement. If the space of workshop permitting, we generally suggest extending equipment 2-3 meters, because the longer, the better improve the effect of impregnation and increase production speed, but also produce thick sheet. |

SERVICE |

1.We have own design team, which can design cost-effective equipment according to customer's needs and the size of the factory. 2. The engineers and technicians in our factory have worked on average more than 10 years, so they have extensive experience in installation and commissioning as well as training. The installation and commissioning for production is crucial, which directly decide the quality of the product and operation of the production. Also rich experience in training can ensure your workers independently achieve the operation. 3.Our equipment guarantee period is up to one year, at the same time our design team every year update the technical, and these new technologies will be notified to our customers to ensure your powerful market competitiveness 4.Every year, we attend the varies of professional composite exhibitions in Moscow,Indian,Singapore ,French and other countries to expand the scale of customers and promote our brand . |