Ductile Iron Flanged Ends Tilting Disc Check Valve with Pn10 Pn16

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 30000PCS/Year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | DICV07 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Power: | Others |

| Standard or Nonstandard: | Standard |

| Pressure: | Medium Pressure |

| Structure: | Check |

| Material: | Others |

| Temperature of Media: | Others |

| Media: | Water |

| Brand Name: | xbvalve |

| Standard: | ANSI |

| Size: | Dn40~Dn900 |

| Specification: | DN40-700 |

| HS Code: | 8481804090 |

| Flow Direction: | Unidirection |

| Application: | Industrial Usage, Water Industrial Usage, Household Usage |

| Inch: | 1-1/2 "~24" |

| Certificate: | ISO, Ce .API RS |

| Transport Package: | Export Polywood Case |

| Production Capacity: | 30000PCS/Year |

| Packing: | Valves are wrapped in plastic bubble sheet & in plywood boxes |

| Delivery Date: | stock or 15 days |

Product Description

Ductile Iron Flanged Ends Tilting Disc Check Valve with PN10 PN16

Ductile Iron Flanged Ends Tilting Disc Check Valve with PN10 PN16

Tilting Check Valve PN10 PN16 DN300-DN1200

Cast Iron Double Disc Wafer Type Check Valve

Ductile Iron Flanged Ends Tilting Disc Check Valve with PN10 PN16

Ductile Iron Flanged Ends Tilting Disc Check Valve with PN10 PN16

Tilting Check Valve PN10 PN16 DN300-DN1200

Cast Iron Double Disc Wafer Type Check Valve

CHECK VALVES

Tilting Disc Check Valve

Tilting Check Valve PN10 PN16 DN300-DN1200

PRODUCTION STANDARDS

| Design: EN12234 | |||||

| Face to Face Dimension: DIN3202 F4 | |||||

| Flange: EN1092-1 | |||||

| Working Pressure: | PN10 | PN16 | |||

| Shell Test: | 1.5Mpa | 2.4Mpa | |||

| Seat Test | 1.1Mpa | 1.8Mpa | |||

| Application: | Water/ Swage | ||||

| Test Standard | DIN32320 | ||||

FEATURES

• Tilting Check Valve, while allowing the flow moving to the desired flow direction,stops the flow when exposed to back flow

• With the start of movement at defined flow direction on the system, the disc leaves the flow section by turning in its axis and allows the flow pass.

• When the flow stops, the disc sits on the machined sealing seat through by force of extra weight and maintains 100% tight sealing.

• The body and the disc can be manufactured as cast iron and ductile iron and sealing seats are manufactured .from stainless steel

• Hydraulic brake system can be assembled to disc closer unit if it is required at project.The rate of closure can be controlled due to tilting check valve with hydraulic brake system and the system passes to static position slightly. The installation equipment protected from impact strength.

APPLICATIONS

Steam, superheated water, hot water, cold water, fluids without acidity or alkalinity properties, chemicals

TEMPERATURE

+140 °C

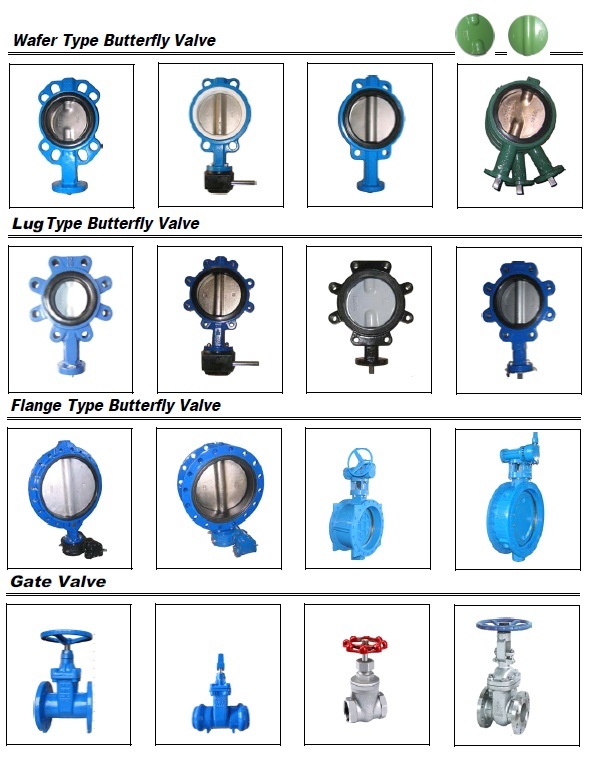

Other products

Why Choose US

Why Choose US

Our factory is specialized in valves' production. As one of the biggest and most professional manufacturer and exporter majored in valves, we assure that we can provide our products with cheapest price, good quality and best service. If you like, welcome to our factory and have a look!

We test leakage of each roll before braiding, then we cut 300mm and crimp it to test

burst pressure after brading.

We use CNC Lathes Machine for end fittings production. Machine system, knife and inspection

tools are all imported from Japan.

We use Techmaflex Crimping Machine which is imported from France. This machine has

accurate and stable performance for crimping because it is produced for PTFE hose crimping only.

Contact to this supplier