BUTT WELD BALL VALVE

| Min. Order: | 3000 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 10 0000pcs per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | JY0095 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Power: | Manual |

| Standard or Nonstandard: | Standard |

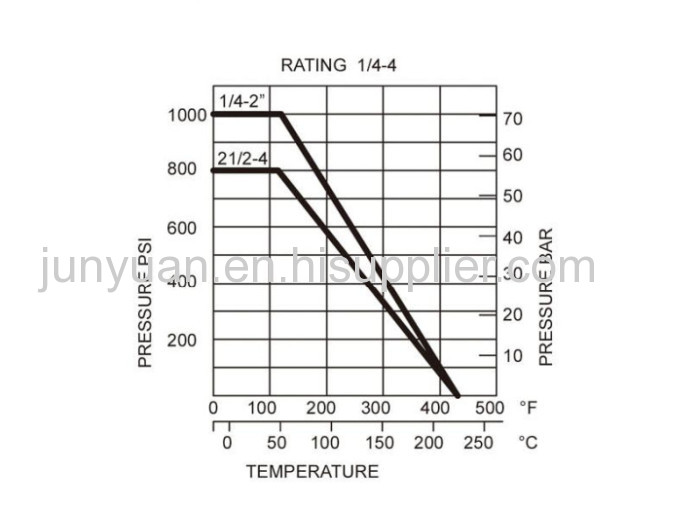

| Pressure: | Medium Pressure |

| Structure: | Ball |

| Material: | Stainless Steel |

| Temperature of Media: | Normal Temperature |

| Media: | Water |

| Brand Name: | JUNYUAN |

| Material: | Stainless steel |

| Size: | 1/4"--2" |

| Thread Connection: | Female Thread,BSP.NPT |

| Working Pressure: | PN25 |

| Technical: | Forged |

| Certificate: | ISO9001, CE,ACS.UL,CSA |

| Brand: | JY or Professional OEM |

| Working Temperature: | -10-110℃ |

| HS Code: | 8481804090 |

| Model Number: | JY0095 |

| Production Capacity: | 10 0000pcs per month |

| Packing: | Polybag, Inner Box, Carton and Wooden Pallets |

| Delivery Date: | Shipped in 35 days after received payment |

Product Description

BUTT WELD BALL VALVE

Features

Product Description :

Raw material

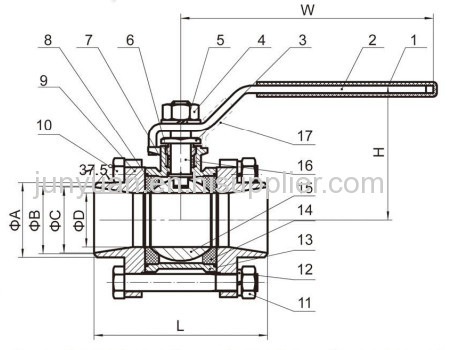

| ITEM | DESIGNATION | MATERIAL |

| 1 | HANDLE SLEEVE | PVC |

| 2 | HANDLE | 304 |

| 3 | GLAND NUT | 304 |

| 4 | STEM NUT | 304 |

| 5 | SPRING WASHER | 304 |

| 6 | STEM PACKING | PTFE |

| 7 | THRUST WASHER | PTFE |

| 8 | JOINT GASKET | PTFE |

| 9 | CAP | CF8/CF8M |

| 10 | BODY | CF8/CF8M |

| 11 | BALL SEAT | RPTFE |

| 12 | BALL | CF8/CF8M |

| 13 | STEM | 304/316 |

Size

| SIZE | D | L | H | W | S | K | M |

| 1/4" | 11 | 58 | 48 | 105 | 26.5 | 27.5 | 10-32UN |

| 3/8" | 12.5 | 58 | 48 | 105 | 26.5 | 27.5 | 10-32UN |

| 1/2" | 12.5 | 58 | 48 | 105 | 26.5 | 27.5 | 10-32UN |

| 3/4" | 17.5 | 79.6 | 67 | 110 | 32 | 34.8 | 10-32UN |

| 1" | 22 | 86 | 70 | 125 | 41 | 34.8 | 10-32UN |

| 1-1/4" | 25 | 103 | 85 | 150 | 50 | 34.8 | 10-32UN |

| 1-1/2" | 32 | 111 | 90 | 150 | 55 | 34.8 | 10-32UN |

| 2" | 38 | 137 | 95 | 190 | 70 | 34.8 | 10-32UN |

Production & Testing

Packaging

.

Certificate

Sale and Market

Why choose us

We control the material of PTFE(Teflon) and stainless steel wires per customer's request.

Some are from Japan and Taiwan, some are from China local. Only choose high quality material.

We test leakage of each roll before braiding, then we cut 300mm and crimp it to test

burst pressure after brading.

We use CNC Lathes Machine for end fittings production. Machine system, knife and inspection

tools are all imported from Japan.

We use Techmaflex Crimping Machine which is imported from France. This machine has

accurate and stable performance for crimping because it is produced for PTFE hose crimping only.

Contact to this supplier