Grooved Pipe Fitting/Equal Tee/grooved tee/

| Min. Order: | 200 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/A, T/T, Money Gram |

| Supply Ability: | 120000 PCS Per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | JY1967 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Head Code: | Others |

| Shape: | Equal |

| Technics: | Casting |

| Type: | Elbow |

| Material: | Iron |

| Connection: | Welding |

| Brand Name: | JY or OEM |

| Certificate: | ISO9001 ,CE |

| Material: | QT450-10 |

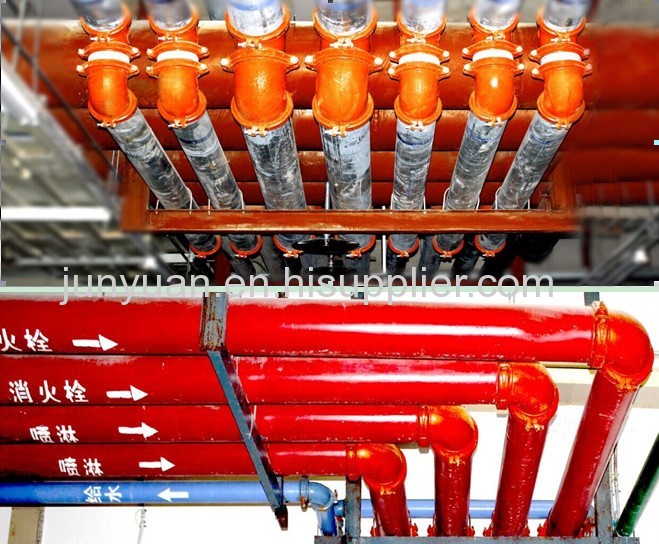

| Usage: | Fire protection engineering,Sprinkler system and others pipe connection |

| Trech Type Pipe Joint: | Rigid coupling,Flexible coupling |

| Trech Type Pipe: | All kinds of Mechanical tee,Mechanical cross,Elbow,the equal and reducing Tee,Cross,Flange,Cap,Blind plate ect |

| Specifications: | 60-530 |

| Working Pressure: | 1.2MPa,1.6Mpa,2.5MPa |

| Production Capacity: | 120000 PCS Per month |

| Packing: | standard carton and pallet |

| Delivery Date: | Shipped in 30 days after payment |

Product Description

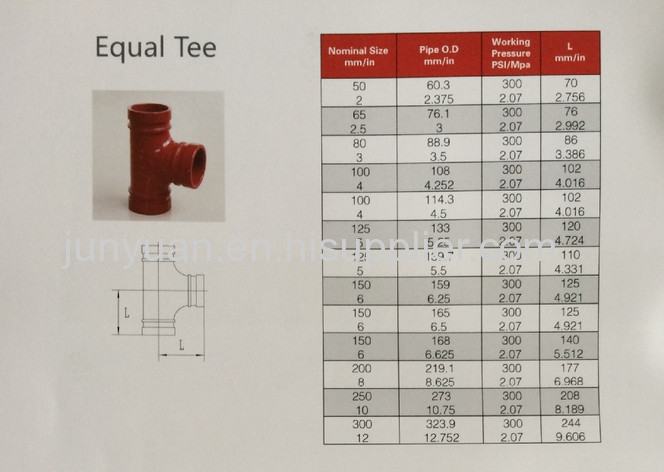

Grooved Pipe Fitting/Equal Tee/grooved tee/

Description of Product

Material | Ductile Iron (ASTM )QT450-10 |

Finish | Paint,Epoxy Powder |

Nominal Size | 1-12 inches |

Color | RAL3000, Blue, White or as per customers' requirement |

Pressure | 300psi, 500psi |

Certificates | FM, UL,CE,CCC & ISO9001 |

Usage | Fire protection, Water supply system, General pipe system , Air-conditioning, Sewage system, Cement pipe system, Mine pipe system |

MOQ | 1 piece |

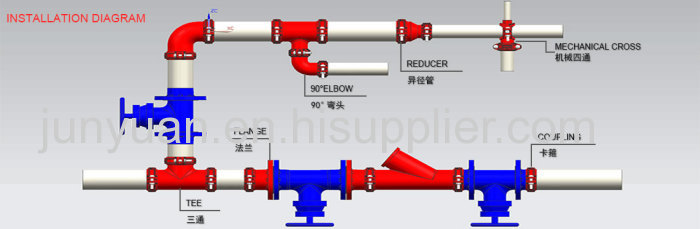

Intallation

Our Services

1. Many years experience in manufacturing and exporting fittings

2. Experienced technical staff

3. Marking the customer's brand on the product surface directly

4. All fittings are approved by CE and ISO

5. Supply OEM service

6. Small orders accepted

7. Competitive prices, top quality, professional service and prompt delivery

8. Quality checking and controlling strictly

Producing

Test of Product

100% raw material 100% self producing 100% pressure test 100% inspection

Packaging

More Products

Company Information

JUNYUAN GROUP is built in Ningbo China .Founded in 1994 junyuan group is a professional manufacturer who dedicates herself to develop and produce within hydro system. After ten years untiring effort,we become an experting company specializing in designing,producing,and marketing her main products: brass & bronze valves and fittings, water meter accessaries and pipe fittings, pump and parts ,PPR inserts,camlock and grooved couplings ect.

During the early period, junyuan group was famed for valve production. In China, we are one of the pioneers of adopting forging and stamping technology into valve production, also we are among the first ones disposing valve exterior techniques based on quality system standard. In the year of 2000, we introduced bronze foundry techniques from United States and started to produce bronze fittings professionally. Now we possesses the most advanced technology and facilities in copper foundry field in China.

JUNYUAN GROUP has various equipments of machining and testing, ability of researching and developing valve and sanitary faucets independently, and capacity of 12000000 pieces valves production in conveyor system per year.

Based On The Spirit " Honesty, Pragmatic, Innovation", We are proud to own One Professional Team and Provided Customer Competitive Prices, Quality Products with On Time Delivery.Also We have strong OEM and ODM ability for clients to supply various valves and fittings for water solution.

JUNYUAN GROUP are Seeking to be the best cooperator for water plumbing and Improve Its worth to Customers. Please Contact Us Freely to know more details about What We can bring for your sourcing Operation.

Certification

FAQ

1.Are you a factory or a trading company?

We are a factory with our own foundry, machining, assembly, test and packing.

2.How can I know the material is correcct and acceptable?

Material certificate (inspection certificate) is available on request.

3.What's the material for your casting of Stainless steel 316 camlock coupling?

The raw material for the body of camlock coupling is CF8M. The material certificate is available on request.

What thread you are manufacturing?

BSP and NPT

4.Can I add logo to the products?

Yes, but we usually have quantity requirement if the client want to add logo to the products. You can contact us for the details.

5.Are you able to design or produce new products for us?

We are always willing to develop new products according to the clients' requirements, we are experienced in stainless steel investment casting and Aluminum gravity casting, so when you have samples or drawing needing a factory to develop for you, we will try our best to help you.

6.What's the pressure ratings for your camlock couplings?

Working pressure:

Sizes from 1/2″ to 4″: 150 psi

Size above 4″ 75 psi

Test pressure:

Sizes from 1/2″ to 4′: 300 psi

Sizes above 4″ 150 psi

7.I cannot find the products I want on your site. Are you able to help me to locate it?

We are not able to put every product we can do on this site, however, we have many years of experience of couplings and related products and are always pleased to try to help you.

8.May I require a sample before deciding to buy from you?

Yes, we can supply samples free of charge if not too many, but we usually require the client to pay the freight.

9.Do you have Min. order amount requirement?

We do not have min. order amount requirement, but we hope the order to be more than US$5000 which the export charge will not occupy a big proportion.Small order usually increase our cost and will result in higher prices.

What's the payment terms you can accept.

We usually require wire transfer (T/T), sometimes we also accept the payment terms to be irrevocable L/C at sight.

10.What's the delivery for an order?

General speaking, the production for an normal order is 30 to 45 days. If the order is big, we may need more time.

why choose us ??

1. Competitive prices

We have our own foundry with machining, assembling, testing all together, we are able to control the cost and quality in every step.

2. High and stable quality in both casting and machining

A. We use standard raw material from big factory, we provide chemical composition if needed.

B. We cast the products by ourselves, our castings are good quality.

C. We use diamond cutting (machining) tool, whip keep the product good quality and shiny.

3. Big volume regular stock

We keep 150000+ pcs of regular casting, semi-finished products and finished products in stock, which enable us to deliver the goods in time.