High Tensile Galvanised Steel CZ Purlin Roll Forming Machine With Auto Decoiler

| Place of Origin: | Zhejiang |

|---|

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | S&G-C Purlin |

|---|

Product Description

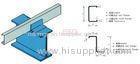

Hi-Tensile Galvanised steel Z Purlin Roll Forming Machine with Auto Decoiler

Introduction of Z Purlin Production Line

This metal roll former is desinged to process galvanized steel coils into high tensile Z shaped purlines within the thickness range 2.0-3.0mm. The punching dies and cutting blades are made by Cr12 mould steel which are with a strong hardness. The whole zee section production line adopts Mitsubishi PLC controller which realizes a full automatic working condition.

Technical Parameters of Z Purlin Manufacturing Machine

| No | Item | Parameter | Remark | |

| 1 |

Suitable

Material |

Type | Galvanized Steel | |

| Thickness(mm) | 2.0-3.0 | According to customer's requirement | ||

| Yield Strength(Mpa) | 230-300 | |||

| 2 | Forming Speed(m/min) | 10 | not including the punching and cutting | |

| 3 | Material of Punching Die | Cr12 steel bearing | with quenching treatment | |

| 4 | Cutting Mode | hydraulic cutting | According to customer's requirement | |

| 5 | Power source | Type | 380V/3PH/50HZ | According to customer's requirement |

Working Flow

Decoiling---->Sheet Guilding---->Rollforming---->Holes Punching---->Hydraulic Cutting---->Finished Z Purlins

Components of Z Purlin Manufacturing Machine