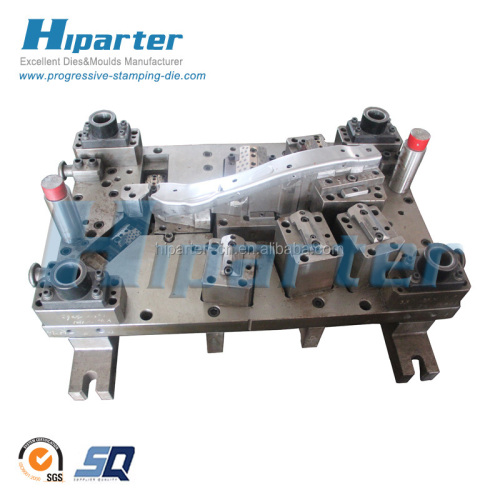

Experienced Professional Customized Punching Forming Metal Auto Stamping Die

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 sets per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | HPD22003 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product Material: | Metal |

| Product: | Vehicle Mould |

| Shaping Mode: | Punching Mold |

| Brand Name: | Hiparter |

| Die procedure:: | Stamping Die |

| Die material:: | DC53 |

| Equipment:: | EDM,Wire Cutting,CNC |

| Die tolerance:: | 0.02mm |

| Spare part:: | MISUMI standard |

| Production Capacity: | 50 sets per month |

| Packing: | wooden case |

| Delivery Date: | in 45 days after confirm the drawing |

Product Description

Hiparter is a professional stamping die manufacturer in north of China.

Custom stamping dies, provide design and manufacturing service.

Insists on providing high-standard and high-quality stamping dies and support.

Die Type | Progressive Stamping Die, Stage Stamping Die, Transfer Stamping Die | ||

Die Material | SKH-9, DC53, SKD11, Cr12Mov, Cr12, 45# | ||

Part Material | Cold steel, Galvanized steel, Stainless steel(SUS301, SUS304, SUS430 ) , etc. | ||

Standard Part | MISUMI, PUNCH, FIBRO, DAYTON, DME, etc. | ||

Manufacturing Machinery | Milling, Grinding, Boring, CNC, EDM, WEDM, Precision Flat Milling, Saw Machine | ||

Press Machinery | 45T~800T, Press machine, Punching machine, Forming machine | ||

Inspection Machinery | CMM, Vision Projector, Micro-callipers, Laser Scanner, Alloy Analyzer | ||

Forming Way | Punching, Blanking, Piercing, Bending, Forming, Deep Drawing, etc. | ||

Die Precision | High precision machining, minimum 0.02mm. | ||

Lead Time | 6 weeks for die buidling, after the die structure drawing confirmed. | ||

Delivery | By sea or air, By air around 2-5 days, By sea around 10-30 days. | ||

Qingdao Hiparter Metal&Plastic Products Co., Ltd. was established in 2003, located in Qingdao, north of China.

Hiparter is a professional manufacturer of single stage stamping dies, progressive dies, transfer dies and injection molds. And also committed to stamping and injection production. With nearly 20 years of development, Hiparter insists on providing high-standard and high-quality dies and support.

Main customers: Haier, Hisense, AUCMA, Midea, KIA, HYUNDAI, TOYOTA, FAW-GM, IKEA, etc.

Export to: US, Canada, Mexico, Brazil, Argentina, Chile, Peru, Ecuador, Japan, Korea, Philippines, Thailand, India, Bangladesh, Russia, Germany, France, Italy, Norway, Poland, Australia, Egypt, Kenya and so on, more than 30 countries.

Provide: Die/Mold design, die/mold manufacturing, stamping production and injection production.

Total solution service: Part design optimization→Die design→Die manufacturing→Die trial&debugging→Part inspection→Die specification manual sharing→After-sales support.

1)3D and CAD/CAM/CAE design, more than 10 stamping die design engineers. Insists on providing high-standard and high-quality stamping dies and support.

2)Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc. Almost all the machining process completed in-house. We can guarantee the quality and lead time.

3)Equipped with Press machine and hydraulic machine, 45T~800T press machines more than 24 sets. Experienced technology engineers and well trained workers. Almost all the stamping die trial completed in-house.

4)Full equiped with inspection machines, including CMM, projector, 3D scanner, Blue scanner, White scanner, Alloy analyzer, etc.