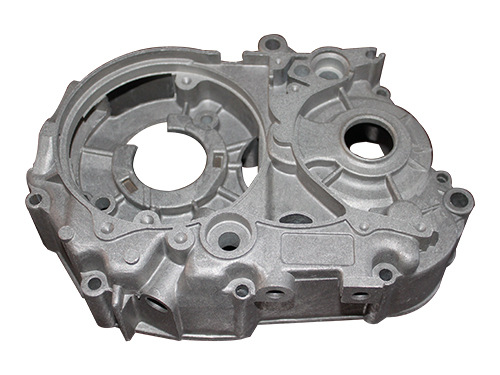

Aluminum Die Casting Instrument Components

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 10000/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SR0104 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Sunrise Metal |

| Company type: | Manufacturer |

| Dimension: | Customized/ upon 3D or 2D drawings |

| weight: | Customized |

| Application: | Electro / Telecommunication |

| Certification: | ISO:9001:2008,SGS,ISO/TS16949 |

| Production Capacity: | 10000/month |

| Packing: | Carton box, pallet or the wooden box or upon requests |

| Delivery Date: | 2-4 weeks |

Product Description

Our factory is a Golden supplier verified by SGS and TS16949 for providing Aluminum Die Casting Parts. These parts are used to large Instrument devices from us in numerous sizes, types and other related options as per the requirements of clients. Also, we provide these die casting parts at reasonable rates in a stipulated time frame.

*More Information about us

1. Sunrise Metal Technology Ltd. Co., locates in Suzhou, China, is a group of one machinery company and three of foundries and machining factories. As a professional Machinery company, we have great experience in producing and exporting various OEM casting, forging parts and machining parts base on client's design or sample. Main material includes Aluminum alloy, Stainless steel, Zinc, Copper, Brass, Titanium, Magnesium, etc.

2.Industrial application of main products in are Aerospace industry, Automotive/motor sports industry, Medical/Life Science, Marine industry, Telecommunications industry, Home appliance, Semiconductor industry, Electro/mechanical industry, Power Generation industry, Industrial equipment and so on.

3. We are SGS verified Golden supplier and we have passed TS16949 Certification.

We focus on one-stop Al Die casting solutions for years, Integrate Rapid Prototyping, Tooling, Die casting, Machining, Sand blasting, Tumbling, Cleaning etc. all in house and out-sourcing other surface Treatments. And our main advantages are below:

1). Very fast delivery time. By our Rapid Prototyping and Fast Molding technology, we can save 50% normal lead time for you.

2). We welcome your low-to-Medium volume requests.

3). Equipped with 7Axis CNC machine, we can do most complicated parts.

4.Factory capacity

Material | Die casting Material: Aluminum A380, ADC12, A360, ADC10,etc; Magnesium AZ91D, AZ30; Zinc (Zamak 3#, Zamak 5#) No-Ferrous Metal:Aluminum 6061-T6,6063-T6,Copper,Brass and Titanium; Steel: Stainless steel SUS304, SUS303,etc. |

Software for drawing | PRO/E, Auto CAD, UG, CAD, PAF, etc. |

Process | Die Casting Raw Material ,Trimming ,Deburring, CNC machining, Surface treatment, package, Shipping & Delivery |

Equipment of Casting | 1.12 sets Die Casting machine(From160T to 1600T) 2. 67 sets advanced CNC machining centers (3axis,4axis,5 axis and 7 axis CNC machine center) 3. 1 set Advanced 3D printer--Made by Stratasys USA. 1 set Carl Zeiss CMM and 2 other brands CMM, etc. |

Good Inspection Instruments | X-ray Detector, CMM, Spectrum Meter, Imaging Measurement Instrument, etc. |

Precision machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

Surface Treatment | powder coating, polishing, sand blasting, heat treatment, painting, anodizing, electroplating, Chrome plating, |

Application (OEM/ODM parts) | Our business primarily serve Aerospace industry, Automotive/motor sports industry, Medical/Life Science, Marine industry, Telecommunications industry, Home appliance, Semiconductor industry, Electro/mechanical industry, Power Generation industry, Industrial equipment, etc. |

Packaging | 1) Polybag and carton 2) Pallet or container 3) As per customized specifications. |

Welcome to contact us.