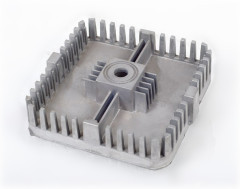

Aluminium safety door locking parts series

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 10000/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SR0094 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Sunrise Metal |

| Company type: | Manufacturer |

| Product type: | new,OEM/ODM/Customized |

| Material: | A380/ADC12/AlSi12,etc |

| Dimension: | Customized/ upon 3D or 2D drawings |

| weight: | Customized |

| Finish: | sand blasting/ polish,etd |

| Application: | Electro / Telecommunication |

| Certification: | ISO:9001:2008,SGS,ISO/TS16949 |

| Production Capacity: | 10000/month |

| Packing: | Carton box, pallet or the wooden box or upon requests |

| Delivery Date: | 2-4 weeks |

Product Description

Our offered Aluminum Die Casting Parts are best in working and provided to the users in many sizes and shapes. These die casting units are made very precisely with the use of best metal. Heat resistant in nature, these aluminum die casting parts are anti corrosive and safe to use in different machines.

We are SGS verified Golden supplier and we have passed TS16949 Certification.

We focus on one-stop Al Die casting solutions for years and our main advantages are below:

1. Very fast delivery time. By our Rapid Prototyping and Fast Molding technology, we can save 50% normal lead time for you.

2. We welcome your low-to-Medium volume requests.

3. Equipped with 7Axis CNC machine, we can do most complicated parts.

Equipped with:

1. 67 sets CNC machines--7Axis/5Axis include.

2. 11 sets Die casting and related tooling equipment.

3. 1 set advanced 3D printer--Made by Stratasys USA.

4. 1 set Carl Zeiss CMM and 2 other brands CMM, etc.

State of the art technologies and materials combined with proven production processes are applied to produce prototypes in metals as following:

No-Ferrous Metal: | Aluminum 6061-T6, 6063-T6, Copper, Brass and Titanium, etc. |

Steel | Stainless steel SUS304, SUS303,etc. |

Die casting Material | Aluminum A380, ADC12, A360, ADC10,etc |

Magnesium AZ91D, AZ30 | |

Zinc (Zamak 3#, Zamak 5#) |

Industries

We can perform small to medium high-pressure die casting with multi-varieties for companies in a wide range of industrial applications including:

Medical | Our die casting company can perform high-quality die casting for medical device customers. Our expertise encompasses essential medical products such as surgical instruments, hospital equipment, hospital bed gearboxes and peristaltic pump pumps. |

Automotive | We proudly provide superior die casting services for automotive manufacturers. |

Aerospace | We're a leading die casting company when it comes to the manufacturing of housings for aerospace. |

Telecommunications | We're an accomplished die cast manufacturer for telecom industry products such as electrical housings, connecting front face plates, waveguides, antenna mounts and RF filters. |

Industrial equipment: | Our die casting services encompass the manufacturing of numerous types of industrial equipment such as ultrasonic scanner, flow control system, textile industry, industrial pumps, and many others. Regardless of the product, our die castings will offer enhanced strength and performance at an extremely low unit cost. |

FAQ

1. Q: What industries does your business primarily serve?

A: Our business primarily serve Aerospace industry, Automotive/motor sports industry, Medical/Life Science, Marine industry, Telecommunications industry, Home appliance, Semiconductor industry, Electro/mechanical industry, Power Generation industry, Industrial equipment, etc.

2. Q: What is your organization on-time delivery percentage for last six months?

A: 100%. We have dedicated reliability group or person at each process of the production. Everything is under control. We will estimate all kinds of problems that maybe occur during produce process and work out the solutions. Every questions will get quick feedback and solutions to ensure on-time delivery and shipment.

3. Q: Is your Mfg. facility certified by any one of the quality standard?

A: Yes, We are SGS verified Golden supplier and we have passed TS16949 Certification, as well as ISO9001 certified.

4. Q: Does your organization have an IP protection policy?

A: We will sign the confidentiality agreement or NDA (Non-Disclosure Agreement) with our customers to protect their patents.

5. Q: Does your organization have an ERP/MRP/ Manufacturing/Shop floor control system?

A: Yes, we have ERP system.

6. Q: Does your organization have a conflict minerals policy? (Applicable with the Dodd Frank law of 2010)

A: Yes, We are aluminum die casting parts manufacturer. We never use mineral materials, but we will sign the CMRT upon customers' requests.

7. Q: Does your organization have a quality department or quality representative to support customer requirements?

A: Yes, we have. We not only have a quality department but also set up a quality group whose member include customer service manager, engineer, and QC manager. We have experienced engineers and quality control team as our strong backing.

8. Q: Is non-conformance material adequately identified to prevent use or shipment?

A: We are aluminum die casting parts manufacturer. All Aluminum ingot is bought from qualified and standard supplier. Thus, we stop the problems at its source to keep our product in good quality all the time.

9. Q: How much time can your organization save through your fast mold manufacturing?

A: we can provide those fast solutions even more rapidly, thanks to our new fast mold manufacturing capabilities. With our advanced, in-house tooling equipment - including 5-axis and precision CNC machines, milling machines, and grinding machines - plus a well-equipped local supply base, we can reduce lead time for prototype tooling by 66% - and shorten production tooling time by 50%.

By combining our fast mold manufacturing with professional communication and an accelerated production pace, we've already helped some of the largest global enterprises dramatically cut their development time for urgent projects, and speed up their time to market.

At Sunrise Metal, we understand that when it comes to sourcing die casting components for your project - time is of the essence. With more than 100 years of combined experience in aluminum die casting and molding, we're able to utilize the latest technology and the best techniques to help you get your project completed. So contact us today, and find out how our fast mold manufacturing, efficient communication, and rapid production capabilities can help you realize your project.

10. Supplier: Do you have project need us to help you? Or do you have other questions need us to answer? Welcome to contact us. Thank you!