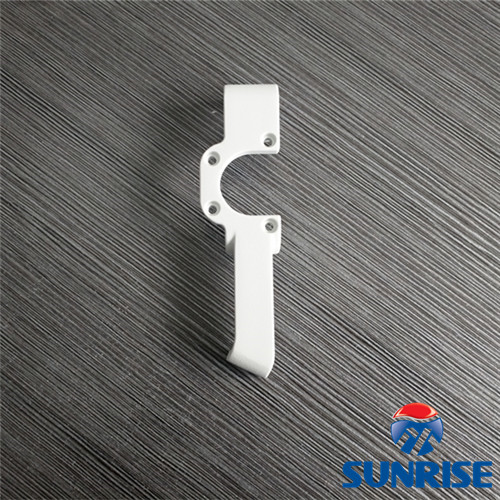

Transducerbase right aluminum die casting manufacturer

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 1000000/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SR0075 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Sunrise Metal |

| Company type: | Manufacturer |

| Product type: | new,OEM/ODM/Customized |

| Material: | Aluminum |

| Dimension: | Customized or estimate by 2D/3D drawings |

| weight: | upon requests or estimate by 2D/3D drawings |

| Finish: | Powder Coating |

| Application: | Medical Parts/Ultrasound system/Diagnosis Equipment,etc |

| Color: | Any color upon request |

| Certification: | ISO:9001:2000,SGS,ISO/TS16949 |

| Production Capacity: | 1000000/month |

| Packing: | Carton box, pallet or the wooden box or upon requests |

| Delivery Date: | 2-4 weeks |

Product Description

With more than 10 years' experience, our 3 facilities dedicate to offer customer aluminum complete solutions including Prototyping, Die Casting Production, Machining from solid, extrusion, forging, etc. We offer One-stop Solution. Integrate Rapid Prototyping, Tooling, Die casting, Machining, Sand blasting, Tumbling, Cleaning etc. all in house and out-sourcing other surface Treatments. High Quality, Fast Production, Fast Response, Friendly service are Our Core Values. Our Market Target are High Mix, Low to Medium Volume Projects. We have an experienced engineer and quality control team as our strong backing. OEM orders are warmly welcomed.

Feature

Sunrise build up the Fast Mold Manufacturing Business Unit. Our fast mold team dedicate to fast mold. We quick react on tooling design, optimize every processes tooling manufacturing, 24 hour's work, utilize our in-house advanced tooling equipment and excellent tooling supply base in our area, design and manufacture tooling innovative ways. We now can shorten tooling manufacturing time by 50% for hard production tooling and can shorten to 1/3 normal tooling lead time for prototyping tooling.

Our fast mold manufacturing has already help our customer such as Marquardt, Hengst, Anologic, etc. to save more than 50% project develop time for their urgent project and speed up their project time to market.

State of the art technologies and materials combined with proven production processes are applied to produce prototypes in metals as following:

No-Ferrous Metal: | Aluminum 6061-T6, 6063-T6, Copper, Brass and Titanium, etc. |

Steel | Stainless steel SUS304, SUS303,etc. |

Die casting Material | Aluminum A380, ADC12, A360, ADC10,etc |

Magnesium AZ91D, AZ30 | |

Zinc (Zamak 3#, Zamak 5#) |

Industries

We can perform small to medium high-pressure die casting with multi-varieties for companies in a wide range of industrial applications including:

Medical | Our die casting company can perform high-quality die casting for medical device customers. Our expertise encompasses essential medical products such as surgical instruments, hospital equipment, hospital bed gearboxes and peristaltic pump pumps. |

Automotive | We proudly provide superior die casting services for automotive manufacturers. |

Aerospace | We're a leading die casting company when it comes to the manufacturing of housings for aerospace. |

Telecommunications | We're an accomplished die cast manufacturer for telecom industry products such as electrical housings, connecting front face plates, waveguides, antenna mounts and RF filters. |

Industrial equipment: | Our die casting services encompass the manufacturing of numerous types of industrial equipment such as ultrasonic scanner, flow control system, textile industry, industrial pumps, and many others. Regardless of the product, our die castings will offer enhanced strength and performance at an extremely low unit cost. |

Our Advantages

1. Strong R&D capability and rich engineering experience enable us,

a. Design Mechanical parts.

b. Design for Manufacturing

c. Cost saving suggestions.

d. PPAP capability

2. One-stop Solution

Integrate Rapid Prototyping, tooling, Die casting, machining, and assembling in house and surface treatments, together with various value-added services

3. Fast delivery

a. Rapid Prototyping: 1-2 weeks for Volume less than 200pcs.

b. Rapid tooling: 2-4 weeks for production tooling, etc.

c. Rapid Production: With Rapid tooling and quick production arrangement, we can provide quick production delivery.

4. Well trained work team

Honest, easy-going, hard-working and able to work under pressure; Well-trained invocational ethic, good mentality and high work efficiency