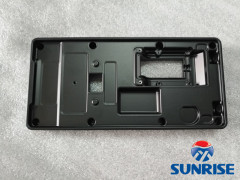

Aluminum enclosure die casting exporter

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 10000pcs/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | S0091 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Sunrise Metal |

| Company type: | Manufacturer |

| Product type: | new,OEM/ODM/Customized |

| Material: | ADC12 |

| Dimension: | 171.5x82.8x18mm/Customized |

| Machine Ton: | 280T/1x1 |

| Application: | Auto Parts/Marine parts/Telecommunication/Medical Parts/ |

| surface treatment: | E-coating |

| Certification: | ISO:9001:2008,SGS,ISO/TS16949 |

| Production Capacity: | 10000pcs/month |

| Packing: | Carton box, pallet or the wooden box or upon requests |

| Delivery Date: | 2-4 weeks |

Product Description

Aluminum die casting parts exporter

Factory Capacity

Mold manufacturing equipments:

Mold manufacturing equipment | Machine Quantity (set) |

5-axis CNC Machine | 2 |

Precision CNC Machine | 4 |

High Speed CNC Machine | 9 |

CNC Machine | 6 |

EDM | 4 |

WEDM | 6 |

Milling Machine | 4 |

Grinding Machine | 3 |

Drilling Machine | 2 |

Sawing Machine | 1 |

Rapid Prototyping equipments:

NO. | Name | Quantity | Stroke |

1 | Mazak 7-axis turning & milling Machine | 1 | Ф658*1011MM |

2 | Mazak /Hass 5-axis CNC Machine | 2 | Ф800/Ф600 |

3 | 3-axis CNC Machine Center | 1 | 2000*1500MM |

4 | 4-axis CNC Machine Center | 12 | Ф250*800MM |

5 | 3-axis CNC Machine Center | 20 | 1000*600*600MM |

6 | CNC Lathes | 2 | Ф320*800/Ф610*1000MM |

7 | Sodick Wire Cutting Machine | 3 | 400*400*200MM |

8 | EDM Machine | 2 | 500*400*400MM |

9 | Surface grinder | 1 | 600*300*200MM |

Die Casting Tooling Equipment

No. | Name | Quantity | Stroke |

1 | High Precision CNC Machine | 4 | Max 1210*1050*810/Min. 600*450*430 |

2 | High Speed CNC Machine | 9 | Max 1800*800*750/Min. 850*520*520 |

3 | CNC Machine | 6 | Max 1500*800*700/Min. 800*550*580 |

4 | DMU monoBLOCK 5-AXIS CNC Machine | 2 | Max 935*850*650/Min 735*650*560 |

5 | EDM Machine | 5 | Max1800*900*1000/Min 450*350*220 |

6 | WEDM Machine | 6 | Max600*400*290/Min400*280*220 |

7 | Grinder | 3 | 1500*600*600 |

8 | Milling Machine | 4 | 1600*800*300 |

9 | Drilling Machine | 2 | 1600*630*400 |

10 | Sawing Machine | 1 | GD6528 |

Die Casting Machining Equipments:

Die Casting Shop 1 (New Shop) | Brand | Ton | Unit |

Aluminum | LK | 280T | 1 |

Aluminum | LK | 400T | 1 |

Aluminum | LK | 500T | 1 |

Aluminum | LK | 800T | 1 |

Aluminum | LK | 160T | 1 |

Aluminum | Toshiba | 250T | 1 |

Aluminum | LK | 280T | 1 |

Aluminum | Toshiba | 350T | 1 |

Aluminum | LK | 400T | 1 |

Zinc | LK | 38T | 1 |

Zinc | LK | 88T | 1 |

Company Information

| About Sunrise Metal | 1) Sunrise metal products plant, is a professional OEM die casting manufacturer with more than 10 years' experience in manufacturing Aluminum mould and die casting. |

| OEM orders are warmly welcomed. | |

| 2) We have an experienced engineer and quality control team as our strong backing. | |

| 3) One-stop solution service help to save time.Integrate Rapid Prototyping, Tooling design & tooling, Die casting, Machining, Sand blasting, Tumbling, Cleaning etc. all in house and out-sourcing other surface Treatments. | |

| Our advantage | 1) Professional technical support |

| 2) Quick response | |

| 3) Strict quality control process | |

| 4) High cost performance | |

| 5) Rich experience in mould design and die casting | |

| 6) Abundant cooperation with occident corporations | |

7) SGS/ISO/TS16949/ERP system guarantee | |

| We can also provide | 1) Mold design & fast mold manufacturing |

| 2) Rapid prototyping | |

| 3) Die casting | |

| 4) CNC Machining & surface treatment |

Fast Mold Manufacturing Business Unit

Sunrise build up the Fast Mold Manufacturing Business Unit. Our fast mold team dedicate to fast mold. We quick react on tooling design, optimize every processes tooling manufacturing, 24 hour's work, utilize our in-house advanced tooling equipments and excellent tooling supply base in our area,design and manufacture tooling innovative ways. We now can shorten tooling manufacturing time by 50% for hard production tooling and can shorten to 1/3 normal tooling lead time for prototyping tooling.

Our fast mold manufacturing has already help our customer such as Marquart, Hengst, Anologic,etc to save more than 50% project develop time for their urgent project and speed up their project time to market.

At Sunrise Metal , we are dedicated to providing you with exceptional service and quality parts you can rely on.

Company views