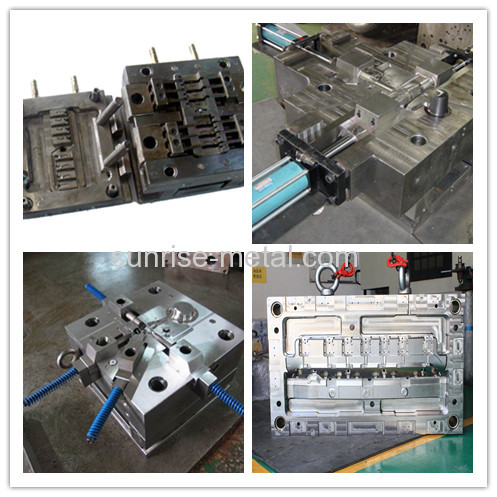

Aluminum Diecasting mold making

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 20 |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | S090 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Sunrise Tooling |

| Cavity material: | H13 |

| Tooling machine Ton: | 800T |

| Tooling lead time: | 4~6weeks |

| Maintance tooling: | in house |

| Cativies: | one cavity |

| Tooling life: | 50~60K shots |

| Tooling Frame material: | #45 steel |

| Capability: | 20~25sets/month |

| Production Capacity: | 20 |

| Packing: | wood carton |

| Delivery Date: | 4~6weeks |

Product Description

Aluminum mould making metal prototyping

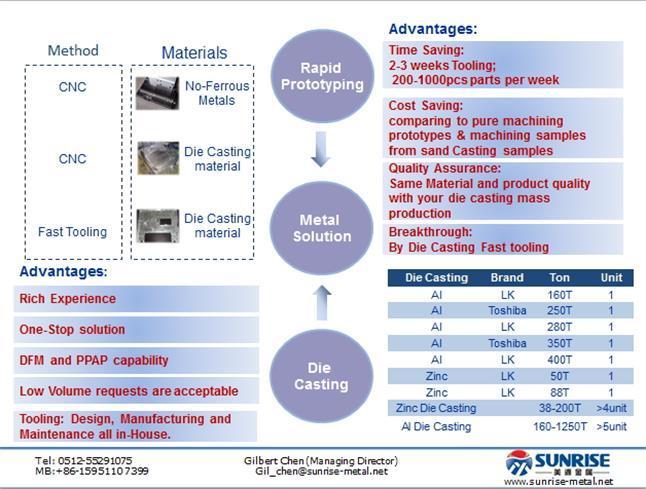

Sunrise Metal provide the following services to customers:

1. Mechanical Engineering service, we have rich experience mechanical engineering team , we help customer to do the mechanical design for product per customer's function and appearance requirement, do the DFM (Design For Manufacturing) for customer's products, tooling design , production design, etc.

2. Rapid Prototyping Service, we provide good service on prototyping with our rich experience team and our advanced machines for prototyping. we target on over 10 sets metal prototype request. We have three ways to make prototype.

① Pure Machining from steel , magnesium , aluminum , zinc, etc , .

② We cast die casting material block such as A380, A413 ,etc with minimum porosity and then machine the prototypes from die casting material. The porosity are rare and acceptable level .

③ We make fast die casting mold ( Half of Normal tooling lead time ) and then cast the prototypes .

3. Die casting In House Service , we target on high mix , small - medium volume projects. With our rich experience on die-casting , high precision die-casting machine , tooling shop in house & well management , we can provide one stop solution for die-casting components.

4. Supply Management Service, our team members have good English capability , rich supply management experience , advanced QC equipment & QC measuring Skills , etc , we help customer to manage their supply in China . Hope we can have chance to work with you.

Factory Capabilities

Material | Aluminum ADC12(Or A380/ADC10 upon requests) |

Process | Die Casting Raw Material → Trimming → Deburring →CNC machining → chromating →powder coating → package → Shipping |

Equipment of Casting | 1.12 sets Die Casting machine(From160T to 1600T) 2. 41 sets advanced CNC machining centers (3axis,4axis, 5 axis and 7 axis CNC machine center) 3. 2 sets CNC Lathes, 2sets drilling machines, etc. |

Good Inspection Instruments | X-ray Detector, CMM, Spectrum Meter, Imaging Measurement Instrument, etc. |

Precision machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

Surface Treatment | powder coating, polishing, sand blasting, heat treatment, painting, anodizing, electroplating, Chrome plating,etc |

Application | Medical Parts, Ultrasound system, Ultrasound devices, Diagnosis Equipment, Hospital machines, Medical devices, Auto parts, marine & ship equipment, Telecommunication, Textile Industry, etc |

Our Unique Feature

Fast Mold Manufacturing

Sunrise build up the Fast Mold Manufacturing Business Unit. Our fast mold team dedicate to fast mold. We quick react on tooling design, optimize every processes tooling manufacturing, 24 hour's work, utilize our in-house advanced tooling equipments and excellent tooling supply base in our area,design and manufacture tooling innovative ways. We now can shorten tooling manufacturing time by 50% for hard production tooling and can shorten to 1/3 normal tooling lead time for prototyping tooling.

Our fast mold manufacturing has already help our customer such as Marquart, Hengst, Anologic,etc to save more than 50% project develop time for their urgent project and speed up their project time to market.