OEM Service for Aluminum Die Casting Investment Casting

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 10000pcs/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | S0017 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Sunrise Metal |

| Company type: | Manufacturer |

| Product type: | new,OEM/ODM/Customized |

| Material: | ADC12 |

| Dimension: | 480x297.6x82.2mm/Customized |

| weight: | 2828/upon request |

| Machine Ton: | 1250T/1x1 |

| Application: | Auto Parts/Marine parts/Telecommunication/Medical Parts/ |

| Color: | Any color upon request |

| Certification: | ISO:9001:2008,SGS,ISO/TS16949 |

| Lead time: | 2-4 weeks |

| Production Capacity: | 10000pcs/month |

| Packing: | Carton box, pallet or the wooden box or upon requests |

| Delivery Date: | 2-4 weeks |

Product Description

Die Casting Investment Casting

Introduction

production pictures

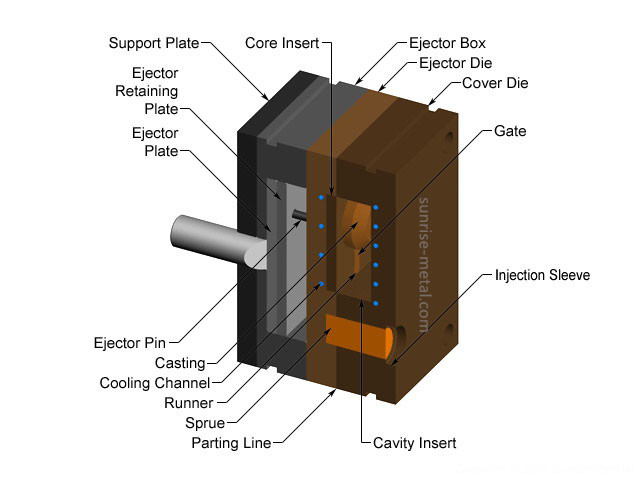

Die casting tooling/Ejector pins

Tooling: Dies and Molds for Die Casting

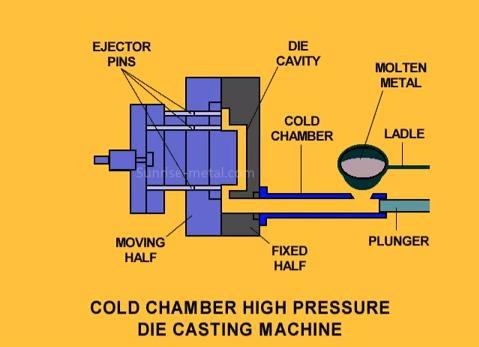

Die cast tooling called insert die, die casting dies, or die casting molds, comes in one part each cycle). Sunrise Metal only uses cold chamber die casting machine tooling dimany styles, sizes, and values. Die cast tooling comes in single cavities (one part each cycle) or multiple cavities (more than es or molds for aluminum die cast parts.

Die cast tooling comes in various forms:

1. Die Cast Tooling Inserts

2. Prototype Die Cast Tooling Inserts

3. Unit Die Tooling

4. Complete Class "A" Die Cast Die or Mold Tooling

5. Die Cast Family Mold Tooling

6. Trim Dies for Die Cast Parts

Our In-House Die Cast Tooling Capabiities include:

Die casting dies.

Die casting molds.

Die casting inserts.

Die cast tooling modifications.

Die cast tooling repairs.

Diecast tooling and trim die manufacture.

Factory Capabilities

Material | 1. Aluminum (A380,ADC10,ADC12), Magnesium (AZ91D,AZ30), Zinc (Zamak3# and Zama 5#) 2. No-Ferrous Metals: Aluminum 6061-T6 , 6063-T6, Copper, Brass and Titanium etc. 3. Stainless Steel, etc. |

Process | Die Casting Raw Material → Trimming → Deburring →CNC machining → E-coating→ package → Shipping,etc. |

Equipment of Casting | 1.12 sets Die Casting machine(From160T to 1600T) 2. 41 sets advanced CNC machining centers (3axis,4axis, 5 axis and 7 axis CNC machine center) 3. 2 sets CNC Lathes, 2sets drilling machines, etc. |

Good Inspection Instruments | X-ray Detector, CMM, Spectrum Meter, Imaging Measurement Instrument, etc. |

CNC turning, milling, drilling, grinding, cutting, reaming and threading etc. | |

Surface Treatment | powder coating, polishing, sand blasting, heat treatment, painting, anodizing, electroplating, Chrome plating,E-coating. |

Application | Auto parts, Medical Parts, Ultrasound system, Ultrasound devices, Diagnosis Equipment, Hospital machines, Medical devices, marine & ship equipment, Telecommunication, Textile Industry, etc |

| Products | All kinds of aluminum casting: include automotive parts, railroad parts,medical parts, marine parts, lighting parts, pump body, valve parts,architectural parts and furniture parts ,etc. |

Company Profile

1. Brief Information.

With more than 10 years of experience, our 3 facilities are dedicated to offering customer aluminum complete solutions including:

a. Prototyping

b. Die Casting Production

c. Machining from solid , extrusion, forging ,etc

2. We offer One-stop Solution .

Integrate Rapid Prototyping, Tooling, Die casting, Machining, Sand blasting, Tumbling, Cleaning etc. all in house and out-sourcing other surface Treatments.

3. Our Core Values:

High Quality , Fast Production, Fast Response , Friendly service

4. Market Target:

High Mix , Low to Medium Volume Projects

Our Advantages

1. Strong R&D capability and rich engineering experience enable us,

a. Design Mechanical parts.

b. Design for Manufacturing

c. Cost saving suggestions.

d. PPAP capability

2. One-stop Solution

Integrate Rapid Prototyping, tooling, Die casting, machining,

assembling in house and surface treatments, together with

various value-added services

3. Fast delivery

a. Rapid Prototyping: 1-2 weeks for Volume less than 200pcs.

b. Rapid tooling: 2-4 weeks for production tooling, etc.

c. Rapid Production: With Rapid tooling and quick production

arrangement, we can provide quick production delivery.

4. Well trained work team

Honest, easy-going, hard-working and able to work under pressure; Well-trained invocational ethic, good mentality and high work efficiency

General view of our factory