Good performance stationary 90m3/h concrete batching plant with layout drawing

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100 |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | HZS90 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | Huaning |

| Maximum Productivity: | 90 m3/h |

| Mixer Model: | JS1500 |

| Batching Model: | PLD2400 |

| Power: | 145 kw |

| Mixing Power: | 2X37 kw |

| Mixing Speed: | 24.5 r/min |

| Work Cycle Time: | 60 s |

| Discharge Capacity: | 1500 L |

| Feed Capacity: | 2400 L |

| Production Capacity: | 100 |

| Packing: | Export Standard Packing |

| Delivery Date: | 7-20 days after receiving the down payments |

Product Description

Pictures of HZS90 concrete batching plant

Quick Information of HZS90 concrete batching plant

Maximum Productivity: 90 m3/h;

Discharge Height: 3.8 m, can be customized;

Main Machine: JS1500 twin-shaft forced concrete mixer

Batching Machine: PLD2400 with the weighing hopper capacity reaching 2400 L.

Brief Introduction of HZS90 concrete batching plant

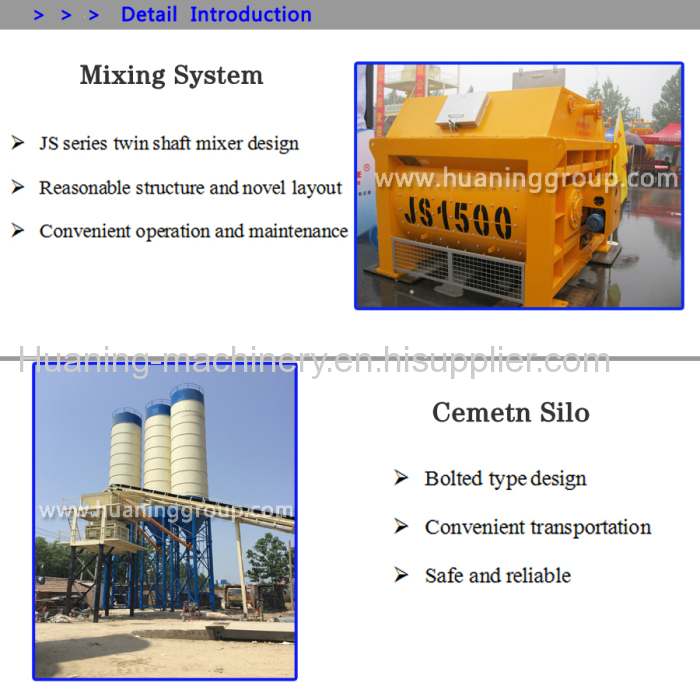

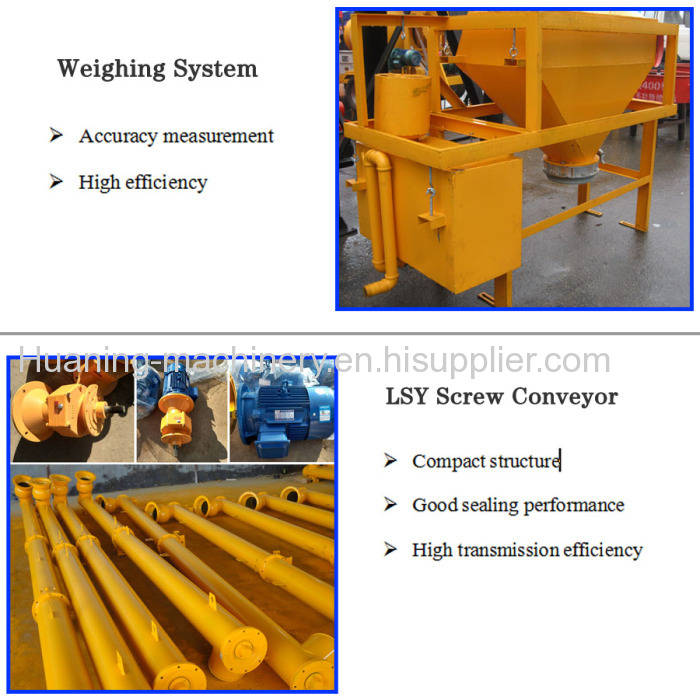

HZS90 concrete batching plant includes the cement silo, screw conveyor, belt conveyor, PLD batching machine, twin-shaft forced concrete mixing machine, computer controlling and measuring system, etc.

And also there are manual control system, automatic head-drop compensation and aggregate moisture compensation.

90m3/h Concrete Mixing Station can be used for industry, construction, road, railway, bridge, water conservation, ports, and so on. Working as the concrete mixing equipment, it can meet the requirements for different forms and specifications.

The Structure of HZS90 concrete batching plant

Characteristics of HZS90 concrete batching plant

The concrete mixer JS1500 (The main machine for the mixing plant) has the strong mixing ability with uniform mixing and high production output. The admixtures are widely mixed by the shafts, and reach the best proportional ratio of uniformity.

The mixing shafts adapt anti-binding technology to prevent the cement from binding on the shafts.

Mixing paddles, arms and blades are made of special high chromium and high manganese alloy materials. The wear resistance of the mixing paddles saves time and cost to replace, and at the same time, improves the machines durability and reliability;

The greasing system, which is controlled by central control system, lubricates the greasing points at the fixed position, fixed time and fixed quantity;

The opening of discharge gate can be adjusted by hydraulic system as per specific requirements.

Parameters of HZS90 concrete batching plant

Model | HZS75 | HZS90 | HZS120 | ||

The Whole Station | Max. Productivity | 75 m3/h | 90 m3/h | 120 m3/h | |

Discharge Height | 3.8 m | 3.8 m | 4 m | ||

Working Cycle | 60 s | 60 s | 60 s | ||

Dimension (LxWxH) | 24350x10595x18704 mm | 58555x12376x18704 mm | 60120x13700x18704 mm | ||

Power | 120 kw | 145 kw | 210 kw | ||

Concrete Mixer | JS1500 | JS1500 | JS2000 | ||

Batching Machine | PLD2400 | PLD2400 | PLD3200 | ||

Pneumatic system | Air Compressor Model | 1.8-7 | 1.8-7 | 1.8-7 | |

Nominal Displacement | 1.67 m3/min | 1.67 m3/min | 1.67 m3/min | ||

Rated Discharge Pressure | 0.8 mpa | 0.8 mpa | 0.8 mpa | ||

Motor power | 11 kw | 11 kw | 15 kw | ||

Measurement Accuracy of Weighing system | Aggregate | ±2% | ±2% | ±2% | |

Cement | ±1% | ±1% | ±1% | ||

Water | ±1% | ±1% | ±1% | ||

Admixture | ±1% | ±1% | ±1% | ||

Drawing of HZS90 concrete batching plant

Products Image of HZS90 concrete batching plant

Packaging & Shipping

1. Delivery time: 15 days after receipt of your deposit.

2. Payment terms: 30% T/T in advance, the balance is paid (by T/T) before delivery.

3. Package:

1).Wire cables are used for fastening the machine on the trailer or inside the container.

2).Cork wood is placed in front or behind the machine to protect it.

3).Plastic film is covered on the machine as a rain-roof.

4).Crane is used during the whole loading.