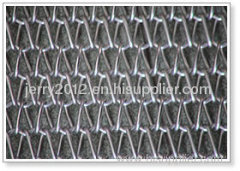

Wire Rope Conveyor Belt

Company Profile

| Location: | Zhangjiagang, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Vibrating Feeder, Disc Feeder, Plate Feeder, Apron Feeder, Crusher |

Product Description

Introduction:

wire rope conveyor belt is a rubber conveyor belt with steel skeleton ,constitute by core glue, rope, cover and side glue. It's advantage is tensile strength, impact resistance, long life, small elongation, good trough ability, flex resistance, good benefits. Suitable for long distance, high leg, high-speed delivery of materials. Widely used in mining, port, power, metallurgy, building materials and other industry requirements under rip stop material handling conditions, it can be used for long-distance transport, large span, large capacity and high speed materials.

product advantages:

1, high strength usage, high safety factor;

2, small elongation, short distances;

3, combined with a solid rope with rubber, excellent dynamic performance;

4, with a soft belt body, a good groove, straight running good;

5, excellent impact resistance;

Tape Standard Specification

Adhesive tape(st-No.)

Max nominal diameter(mm)

Wire rope structure

Rope distance(mm)

Standard work force(N/mm)

Thicknesst1t2 (mm)

Kg/m²

Min diameter roller(mm)

Wire rope strength KN/root

St-630

3

K6x7+1WS

10

90

5x5

19.1

800

6.93

St-800

3.5

K6x7+1WS

10

110

5x5

20.6

800

8.8

St-1000

4

K6x7+1WS

12

140

6x6

24.7

800

13.2

St-1250

4.5

K6x7+1WS

12

175

6x6

25.4

800

16.5

St-1600

5

K6x19+1WS

12

225

6x6

26

1000

21.12

St-2000

6

K6x19+1WS

12

285

8x6

30

1000

26.4

St-2500

7.2

K6x19W+1WS

15

355

8x6

32.2

1250

41.25

St-3150

8.1

K6x19W+1WS

15

450

8x8

35.7

1400

51.98

St-3500

8.6

K6x19W+1WS

15

500

8x8

44.9

1500

57.7

St-4000

8.9

K6x19W+1WS

15

570

8x8

46.6

1600

66

St-4500

9.7

K6x19W+1WS

16

645

8x8

49

1800

79.2

St-5000

10.9

K6x19W+1WS

17

715

8.5x8.5

53.6

1800

93.5

St-5400

11.3

K6x19W+1WS

17

760

9x9

57.5

2000

101

Number of steel wire ropes

Bandwidth(mm)

St630

St800

St1000

St1250

St1600

St2000

St2500

St3150

800

75

75

63

63

63

63

50

50

1000

95

95

79

79

79

79

64

64

1200

113

113

94

94

94

94

76

76

1400

133

133

111

111

111

111

89

89

1600

151

151

126

126

126

126

101

101

1800

171

143

143

143

143

114

114

2000

159

159

159

159

128

128

2200

176

141

141

2400

193

155

155

Cover the performance level and

Test items

Performance index

GB9770-2001

DIN22131

D grade

H grade

L grade

P grade

W grade

X grade

Y grade

Tensile strength Mpa≥

18

25

20

14

18

25

20

Elongation at break %≥

400

450

400

350

400

450

400

(70℃/ 7D)Aging test %

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

Tensile strength change rate %

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

Elongation rate %

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

-25 ~ +25

Wear quantity ≤

90MM³

120MM³

150MM³

200MM³

90MM³

120MM³

150MM³

Number of steel wire ropes

Strong

St630

St800

St1000

St1250

St1600

St2000

St2500

St3150

St3500

St4000

St4500

St5000

St5400

Adhesive strength(N/mm)

60

70

85

95

105

105

130

140

145

150

165

175

180

GB9770-2001

Adhesive strength(N/mm)

60

70

85

95

105

105

130

140

145

150

165

175

180

DIN22131-88

.jpg)