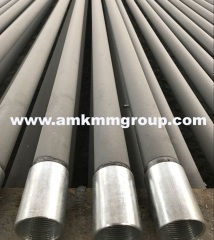

Calorized and ceramic coated oxygen lance pipe

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 5000MT |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | AMK-02 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Material: | mild steel |

| Surface treatment: | ceramic coated and calorized |

| Length: | 4-6 meters |

| Pipe type: | welded or seamless |

| Diameter: | 1/8-2 inches |

| Production Capacity: | 5000MT |

| Packing: | Woven bags |

| Delivery Date: | 20 days |

Product Description

Oxygen Lance Pipe

1. Plain oxygen lance pipe

2. Ceramic coated oxygen lance pipe

3. Calorized oxygen lance pipe

4. Ceramic coated and calorized oxygen lance pipe

Welded tube and seamless tube is available.

We supply all the types of oxygen lance pipes according to your requirement.

Oxygen Lance is a hollow electric welded tube used in various sizes from 1/8″ to 2″ inside diameter.

Oxygen Lance Pipe comes in a variety of end finishes. End caps are provided to prevent contamination. Oxygen Lancing is a reliable method for tapping heats or for other production operations.

Oxygen Lance Pipe is used to remove the carbon from molten metal. During the steelmaking process, a desired carbon content is attained by injecting oxygen into the molten metal. This process is used in blast furnaces, basic oxygen furnaces and also induction and electric furnaces

Lances are used for opening furnace tap holes, cleaning ladle well blocks, unclogging tundish nozzles, cutting ferrous materials, providing the steel or iron is hot enough to sustain burning, ie cutting skulls, spill clean-up, etc

Material: welded steel pipe( carbon steel or seamless steel for your choice)

Heat resistance: 1650-1850ºC

Features:

1. Anti-corrosion, anti-sulphurization, anti-oxidation

2. High thermal resistance

3. Longer service life, steel consumption reduced

4. Oxygen/ powder injection efficiency improved

5. Labor intensity reduced (time to replace the pipes reduced)

6. Graphite electrode consumption reduced

7. Melting time reduced

Supply range:

1. Diameter: From 1/8" to 2" for your choice

2. Length: From 2.5 meters to 6 meters (customized)

3. Coating: 0.2mm-0.8mm ;7.5-9.5mm (customized)

.jpg)

.jpg)