Copper mould tube for continuous casting machine

| Min. Order: | 2 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAP |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 35000PCS |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

Product Detail

| Model No.: | AMK-01 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Others |

| Processing Type: | Machining Equipment |

| Brand Name: | AMK |

| Material: | CUDHP, CUAG0.1, CUCRZR |

| Hardness: | Min.85 HB |

| Melting point: | 1083 |

| Radius: | 3000-17000mm |

| Length: | 602-1100mm |

| Elonggation: | 20% |

| Thickness: | 6-50mm |

| Tensile strength: | 200-445 Mpa |

| Coatings: | Cr, Cr-Ni |

| Cu content: | 99.9% |

| Production Capacity: | 35000PCS |

| Packing: | Wooden case |

| Delivery Date: | 45 days |

Product Description

Product Description

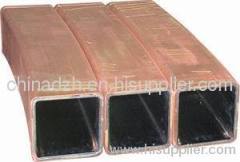

Copper mould tubes for CCM

Copper mould tubes are used as a cooling spare part for continuous casting machines.

1. Square copper mould tube

2. Rectangular copper mould tube

3. Round copper mould tube

4. Beam blank copper mould tube

5. Non-standard copper mould tube

Square Mould

50X50~650X650

Rectangular (100~500)X650

Round mould Ф110-Ф1500

Design with double taper, triple taper

Multi-taper, parabolic taper and various kinds of continuous taper

Non-standard mould

Beam blank mould

Material

The materials of copper mould tubes should be the ones with good tensile strength, fatigue strength, proper hardness, low elongation and high heat conductivity coefficient. As a result, material like phosphorous deoxidize copper(DHP),CUAG,CR-ZR-CU are widely accepted by users of all countries.

Coatings:

Copper has lower hardness which leads to lower anti-abrasive property. Therefore, the area at the lower part of the moulds, where the stress increases drastically due to shells, will be more severely worn. To increase the life time of copper moulds, Uniform mould interior surface plating with suitable hardness is needed. Most of the copper mould tubes for small size billet casting are not used in any casting system where there are rigid casting stream support, therefore they are very sensitiveto be worn. We use hard chrome plating to increase the life of mould tubes. The plating thickness will be controlled in the best range. As for the coating of copper mould plates,based on our years of experience, we are able to provide Cr coating, Ni-Cr coating, Ni-Fe coating and Ni-Cr coating to meet the demand of various customers both at home and abroad.