Microduct Tube Extrusion Machine 5mm-18mm

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Single |

| Brand Name: | KAIDE |

| Power: | 125KW |

| Name: | Microduct Tube Making Machine |

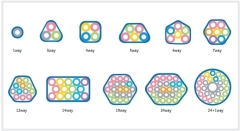

| Pipe Diameter: | 5mm-18mm |

| Line Speed: | 30m/min, 50m/min |

| Keyword: | Microduct Tube Extrusion Machine |

| Production Capacity: | 20 |

| Packing: | soft package for sea transprotion |

| Delivery Date: | 60 days |

Product Description

Micro Duct PE Silicone Core Pipe Production Line

This Micro Duct PE Silicone Pipe Machine use to produce two layers duct PE pipe,called HDPE Microducts, this kind of pipe is used in Telecommunication fields. Microducts is the small, flexible, light weight tube for the installation of fibre optical cables.

| Model | Extruder 1 | Extruder 2 | Production Speed | Line | Nominal |

| Length | Power | ||||

| KDGX-1 | SJ-65/33 | SJ30/25 | 15m/min | 22mx3.5mx2.5m | 75KW |

| KDGX-2 | SJ-60/36 | SJ45/30 | 30m/min | 35mx4mx3.0m | 135KW |

| KDGX-3 | SJ-75/36 | SJ50/33 | 50m/min | 50mx4mx4.5m | 190KW |

High Precision Mechanical Components

(1)The screw of HDPE Extruder and Silicone core Extruder are specially precoessed, provide the excellent plasticization and high extrusion output.

(2)The die head moulds material is high quality 3Cr13 .

(3)High precision and high speed haul-off machine,with servo motor drive, guaranteed the line stable production, specially designed for smaller pipe hauling.

Series Advanced Control & Detecting System

(1) Advanced Siemens PLC control system was applied into this HDPE Silicone core pipe making machine.

(2) High precise control system of pipe weight per meter is applied in this HDPE silicone core microducts making machinery. Such device will feed material precisely accroding to the weight per meter and line speed changing; to get a precise gram weight control of the final pipe,saving raw materials.

Double Working Position Coiler

(1) Traversing unit is driven by servo motor, ensuring the elagant and tidy final coils.

(2) Independent Siemens PLC control, equipped with tension controller.