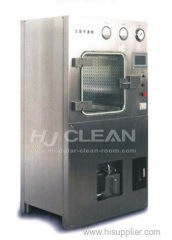

Sterile pass box for cleanroom

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 200sets per month |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | HJCLEAN |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HJCLEAN TECH |

| Product name: | Sterile pass box for cleanroom |

| Production Capacity: | 200sets per month |

| Packing: | Wooden package for sea shipment. |

| Delivery Date: | 30 days |

Product Description

Principle

Provide the best solution to move raw materials from classless/low class clean areas to class A/B

areas, fully meeting the control requirements of GMP-2010 on sterile manufacturing environment.

The sterile pass box is used for biological decontamination on the surface of raw materials to

avoid materials carrying contamination from classless/low class clean areas to class A/B areas. It

is used to pass various clean and dry goods in sterile production, such as packaging materials,

instrument, raw material packaging, accessories, and environmental monitoring equipment.

Product Dimensions

Model 1500: overall dimensions (L×W×H): 1795×1200×1800mm

Chamber size (L×W×H): 1100×1100×1200mm

Model 600: overall dimensions (L×W×H): 1495×900×1600mm

Chamber size (L×W×H): 800×800×1000mm

Model 125: overall dimensions (L×W×H): 1000×880×1790mm

Chamber size (L×W×H): 500×700×500mm

Note: Other sizes can be customized.

Features:

The sterile pass box uses vaporized hydrogen peroxide (VHP) as the biological detergent to

effectively kill fungi, bacteria propagules and spores, viruses, mycoplasmas and other microorganisms.VHPS is a decontamination process under low temperature and atmospheric pressure, featuring broad

spectrum, high efficiency and environmental protection;

The running of sterile pass box is controlled by SIEMENS programmable logic controller

(PLC)automatically, and the system is stable and reliable;

In biological decontamination and exhaust phase, the air sent into the cabin is filtered by H14 HEPA filter to prevent materials from contamination;

The sterile pass box has independent ventilation and exhaust unit, including fan, pneumatic

butterfly valve and exhaust pipe, which can quickly replace the hydrogen peroxide gas in the cabin

and avoid it entering HVAC system; material inlet/outlet is of double-door structure with pneumatic sealing, pneumatic locking and two-door interlock in operating state;

The inner wall is polished, and the welding and the fillet meet GMP requirements;

The sterile pass box has a trolley-type bracket with a track system to facilitate material

handling.The system monitors the temperature, relative humidity and pressure in the pass box in real

time. Testing ports of hydrogen peroxide concentration, dust particles and planktonic bacteria are

optional;

The sterile pass box features easy verification and good reproducibility, with complete IQ,

OQ and PQ files, and on-site verification.