Long Span Truss Structure Train Station Roof

| Min. Order: | 5 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3000ton |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Brand Name: | HANYU |

| Standard:: | GB ISO |

| Place of Origin: | Zhengjiang(Mainland) |

| Type: | Light |

| Grade: | Q235B,Q345B |

| Brand Name: | HanYu |

| Application: | Train Station Roof |

| Dimensions:: | Custom by customer |

| Model Number: | Light steel structure |

| Surface finish: | painting or hot-dip galvanized |

| Main structure:: | H type column, Z type purlin, C type purlin |

| Production Capacity: | 3000ton |

| Packing: | Our packing always according to customer requirements |

| Delivery Date: | In 60 days upon receipt of 40% deposit. |

Product Description

Long Span Truss Structure Train Station Roof

PRODUCT DESCRIPTION

| Material | Mild Steel; Stainless Steel |

| Coating | Spray Painting; Galvanization;Powder Coated |

| Color | Blue; Green; Darkgray; Client's Request |

| Steel code | Q235-B; Q345-B; Stainless steel |

| Fabrication | Advanced Automatic Welding Machines |

| Quality control | GB/T19001-2000----ISO9001:2000 |

| Advantages | 1.Stable and Aesthetic 2.Structure is durable for 50years 3.Fast and easy to install 4.Extensive Applications: Storage, Warehouse, Exhibition Hall,Terminal Building, Stadium, Theater, Special-shaped Buildings, etc 5.High anti-rust performance 6.Flexible composition: Doors and Day-lighting roof could be installed at any position |

Ⅰ. Material grade

1.Carbon structural steel: Q235.

2.High-strength structural steel :Q345

3.Special purpose steel t

Ⅱ,Quality standard

1.Certificate: ISO9001:2000

2.Code for design of steel structure: GB 50017-2003

3.Technical code of cold-formed thin-wall steel structure: GB50018-2002

4.Load code for the design of building structures. GB 50009-2006

5.Construction quality acceptance of steel: GB50205-2001

6.Code for design, construction and acceptance of high strength for steel structure, JGJ82-2011

7.Technical specification for welding of steel structure building: JGJ 81-2002

8.Technical specification for steel Structures of tall buildings: (JGJ99-98)

Ⅲ. Structure Assembly

1.Steel Framework:

Component: H-Column, H-Beam & C/Z-Purlin

Connection of steel structure method: Welding, Bolted

2.Surface treatment: Painting, Galvanized

3.Roof &Wall: colored steel tiles or colored steel sandwich panel as per

request

4.Doors: Rolling or Pushing, as request

V. Steel characteristics

1.Environmental protection

2.Higher reliability of steel work

3.Strong quakeproof

4.Higher degree of industrialization

5.Quick to be assembled accurately

6.Larger interior space

Factory show:

About Hanyu

Hanyu Steel Structure Group Co., Ltd with registered capital of 120 million yuan, mainly specializes in steel structure and deals in curtain wall, steel materials, international trade and cultural undertakings.

Our company consists of two production bases in Hangzhou and Sichuan respectively, covering an overall area of 300 hectares, of which workshop area totals 80000 square meters. Boasting 6 space frame production lines, 4 truss structure lines, 7 light steel lines and 2 new-type foam concrete lines, our company is able to annually fabricate 200000 tons of steel structure, space frame and truss structure, and perform the project with construction area over one million square meter. Our company largely specializes in the diversified production of light steel structure, space frame structure, pipe truss structure, prefabricated houses, curtain walls, membrane structure and new-type foam concrete.

Marketing

Our company has obtained qualification and honor

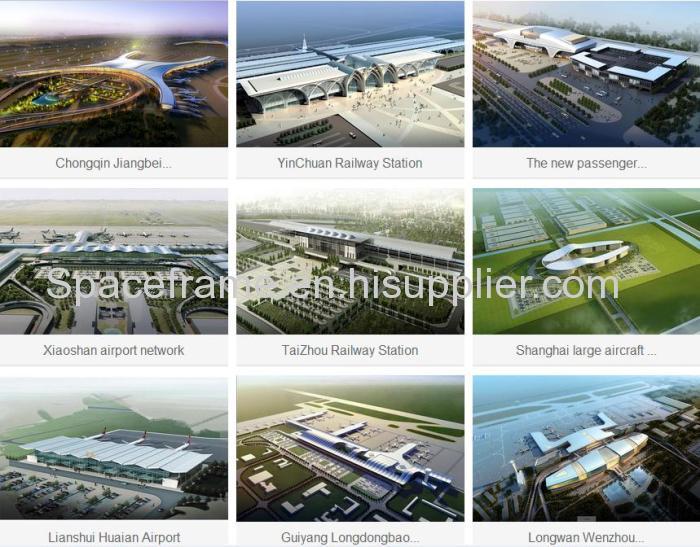

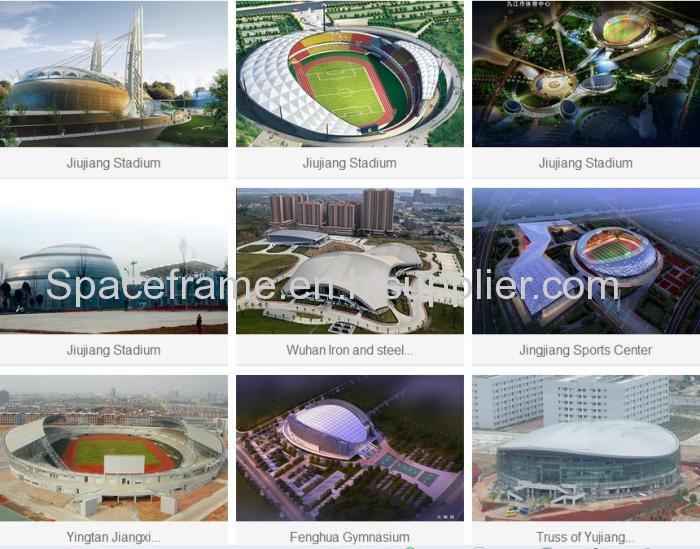

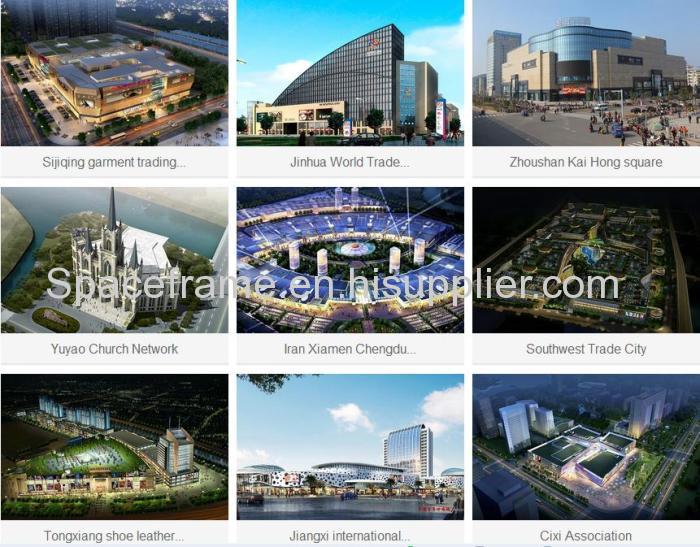

Our projects:

Packing

Why choose us ?

1. Customer-oriented

We can provide you design and an accurate quote within 1-3 business days. We price our buildings economically to save our customers the most money without sacrificing engineering integrity or safety. We are always listening. And ready to find a solution that works for you.

2. Full technology and engineer support

1) More than 80 professional technicians and qualified R&D Engineers.

2) Based on the concept of modern design and corresponding national standards.

3) Most optimized design high-efficiently with the use of advanced internal aid design software, such as PKPM and 3D3S.

4) Complete set of building and installation drawings to ensure the high-efficient and accurate operation.

5) Skilled abroad erection team can make the building erection fast, safe and qualified.

3. Strict quality control

We perform strict quality control system for material, fabrication process and completion. Execute the third party inspection e.g. SGS/BV. The performance of our fabrications is higher 20%~40% than other factories.

FAQ

1. Q: Order process?

A: . Floor plan layout - Confirmation of building materials - Specific quotation - Place the order - Shop drawings - Manufacture - Shipping - Installation

2. Q: How to pay?

A: T/T - 30% deposit in advance, 70% balance before shippment. OR L/C At sight.

3. Q: What is the delivery time?

A: Generally speaking, the delivery time will be within 15 - 30 days.

4. Q: How to deliver?

A: Delivered by 40ft GP / HQ / OT Shipping containers.

5. Q: How to install?

A: We will provide detailed illustration photos and videos to you. If it is necessary, we will send professional engineers to do the constructuion guidance, and some skilled workers to help installation. However, the visa fee, air tickets, accommodation, wages will be borne by buyers.