Steel truss structure for chicken coop chicken shed farm

| Min. Order: | 5 Ton |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3000ton |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Brand Name: | HANYU |

| Standard:: | GB ISO |

| Place of Origin: | Zhengjiang(Mainland) |

| Type: | Light |

| Grade: | Q235B,Q345B |

| Brand Name: | HanYu |

| Application: | chicken coop |

| Dimensions:: | Custom by customer |

| Model Number: | Light steel structure |

| Surface finish: | painting or hot-dip galvanized |

| Main structure:: | H type column, Z type purlin, C type purlin |

| Production Capacity: | 3000ton |

| Packing: | Our packing always according to customer requirements |

| Delivery Date: | In 60 days upon receipt of 40% deposit. |

Product Description

Steel truss structure for chicken coop chicken shed farm

Product Description

| Type | 3 Tiers | 3 Tiers | 3 Tiers | 4 Tiers |

| Size per unit(L*W*H) | 1.95x2.1x1.5 | 1.88x2.1x1.5 | 2.05x2.1x1.5 | 1.88 x2.1x1.8 |

| Size per cell (CM) | 39x35x38 | 47x35x38 | 51x38x38 | 47x35x38 |

| Cell capacity | 3 birds per cell | 4 birds per cell | 5 birds per cell | 4 birds per cell |

| Door | 5 doors | 4 doors | 4 doors | 4 doors |

| Cage | 6 pcs | 6pcs | 6pcs | 8pcs |

| Set capacity | 90 birds | 96 birds | 120 birds | 128 birds |

| Surface treatment | 1.cold galvanized : surface smooth and bright ; color both Gold And Silver; the price is low ; In the humid conditions,it is easy to rust,but not afffect use ,Most clients use it. lifespan: 8-10 years | |||

| 2.Hot dip galvanized : surface zinc is thick, high stength Corrosion Resistance ; color is Silver; the price is higher; lifespan: 20 years | ||||

| 3.PVC powder coated:surface smooth and bright;color can choose ;high stength Corrosion Resistance ;the price is higer ,lifespan:20 years | ||||

| Raise period | 16 weeks to 72 weeks | |||

| Accessories | Cage, cage frame, water pipe,water tank, drinkers, feeders, other necessary fittings | |||

| Drinking system is automatic. | ||||

Structural Steel Buildings' Advantages:

1. Easy Installation

The steel frames are accurately engineered to fit simultaneously, with one end skidding into the other. No exceptional fasteners are required, and fewer employees are required to entire the process. No cutting, retaining, and hammering simultaneously long, hefty and bulky planks.

2. Cost effective

Since the steel is accurately slashed while manufacturing, there is no on location waste (no require to yield for somewhat longer timber to confirm they are long sufficient which you then slash down to size). Since fewer employees are required, that is less salaries to yield if you are having the construction gathered by somebody else.

3. Environmentally Friendly

Recyclable is an environmental benefit of steel buildings using in construction. Steel is the most recycled material in the world. Most manufacturers use recycled steel in all of their steel building materials.

4. Energy Savings

Energy efficiency is one element that points to an environmentally friendly building. Steel buildings fit this description in many different ways. Window placement, Tinted Windows, Insulated Frames, Vapor Retarders between the foundation and concrete slab.

5. Safe and resistant

Steel frame buildings are conspicuously more blaze resistant than a wood framed constructions, steel is furthermore unaffected by termites, bugs or rodents as well as mold or fungi. It does not have to be treated with chemicals like timber does, and a steel frame building is well grounded and less probable to be hit or impaired by lightning.

6. Improved construction quality

A steel frame building does not age and worsen like wooden structures manage over time, so as a homeowner you don't have to concern about any feeble spots. Steel is corrosion resistant, it is dimensionally steady and it furthermore continues directly, no anxieties about distorting with climate changes.

7. Durability:

Steel has one of the largest powers to heaviness ratios of any building material, so is large for a garage kit. Steel will not ever buckle, divide, distort, rotate, chink, rot or splinter. All this power, yet it is furthermore weighs less than timber, producing it simpler to handle, proceed round and construct with particularly when lifting partitions and roofs.

Factory show:

About Hanyu

Hanyu Steel Structure Group Co., Ltd with registered capital of 120 million yuan, mainly specializes in steel structure and deals in curtain wall, steel materials, international trade and cultural undertakings.

Our company consists of two production bases in Hangzhou and Sichuan respectively, covering an overall area of 300 hectares, of which workshop area totals 80000 square meters. Boasting 6 space frame production lines, 4 truss structure lines, 7 light steel lines and 2 new-type foam concrete lines, our company is able to annually fabricate 200000 tons of steel structure, space frame and truss structure, and perform the project with construction area over one million square meter. Our company largely specializes in the diversified production of light steel structure, space frame structure, pipe truss structure, prefabricated houses, curtain walls, membrane structure and new-type foam concrete.

Marketing

Our company has obtained qualification and honor

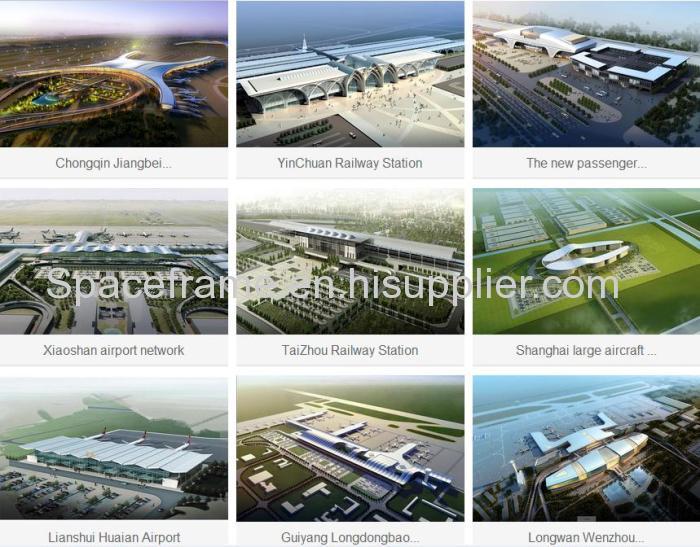

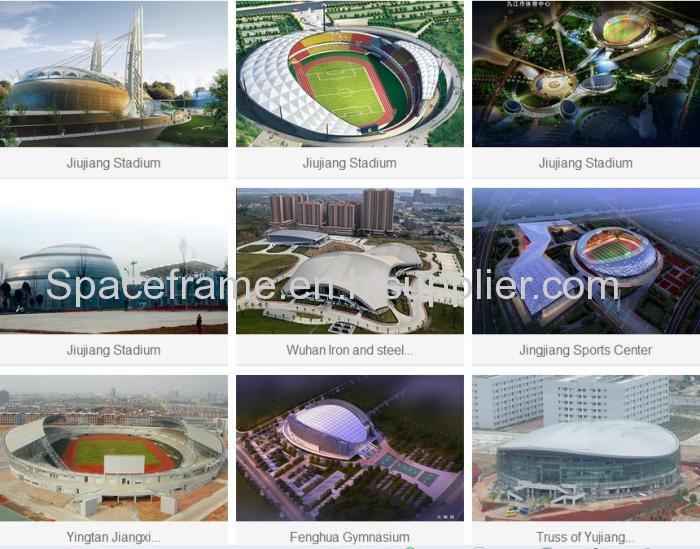

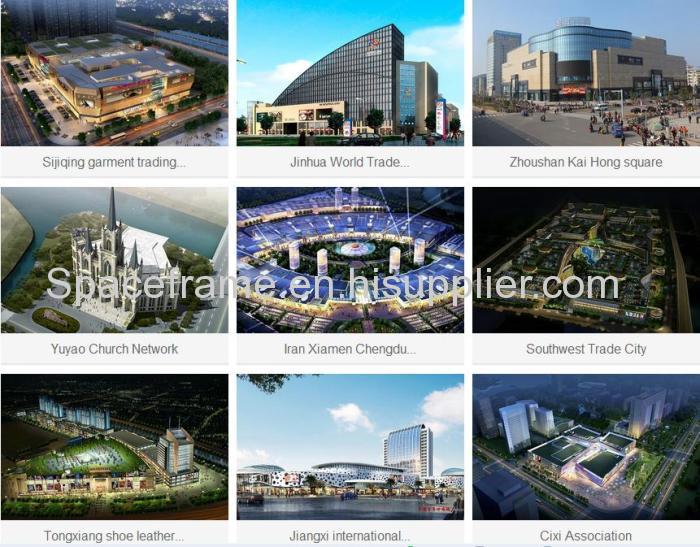

Our projects:

Packing

Why choose us ?

1. Customer-oriented

We can provide you design and an accurate quote within 1-3 business days. We price our buildings economically to save our customers the most money without sacrificing engineering integrity or safety. We are always listening. And ready to find a solution that works for you.

2. Full technology and engineer support

1) More than 80 professional technicians and qualified R&D Engineers.

2) Based on the concept of modern design and corresponding national standards.

3) Most optimized design high-efficiently with the use of advanced internal aid design software, such as PKPM and 3D3S.

4) Complete set of building and installation drawings to ensure the high-efficient and accurate operation.

5) Skilled abroad erection team can make the building erection fast, safe and qualified.

3. Strict quality control

We perform strict quality control system for material, fabrication process and completion. Execute the third party inspection e.g. SGS/BV. The performance of our fabrications is higher 20%~40% than other factories.

FAQ

1. Q: Order process?

A: . Floor plan layout - Confirmation of building materials - Specific quotation - Place the order - Shop drawings - Manufacture - Shipping - Installation

2. Q: How to pay?

A: T/T - 30% deposit in advance, 70% balance before shippment. OR L/C At sight.

3. Q: What is the delivery time?

A: Generally speaking, the delivery time will be within 15 - 30 days.

4. Q: How to deliver?

A: Delivered by 40ft GP / HQ / OT Shipping containers.

5. Q: How to install?

A: We will provide detailed illustration photos and videos to you. If it is necessary, we will send professional engineers to do the constructuion guidance, and some skilled workers to help installation. However, the visa fee, air tickets, accommodation, wages will be borne by buyers.