Electrical Tuck in Device For Rapier

| Min. Order: | 20 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 1000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Shaoxing, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | ZRB561E |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Use: | Weaving Machinery |

| Type: | Others |

| Brand Name: | HEQUN |

| Driving Type: | By Gear |

| Color: | White and Green |

| Composition: | Left and Right |

| Width of Selvedge: | 8-11mm |

| Suitable Speed For Looms: | 350r/min |

| Suitable Range: | According To The Loom |

| Mountung Method: | In High Position(one in each side) |

| Package: | Carton Package |

| Package Size: | 400mmX400mmX390mm |

| Package Weight: | 25kgs |

| Production Capacity: | 1000 |

| Packing: | carton |

| Delivery Date: | 10 Days after T/T Advanced |

Product Description

Products:

1.Mechatronic Tuck in device ,including tuck in mechanical device,servo motor,servo control system, its mechanical device is driven by servo system trough the servo motor.

2. Mechatronic tuck in device driving type including one drives one, one drive several.

3.Its servo control part can be independent or can be installed in the loom cabinet.

4.Cabinet with touch screen,can be edited due to the weaving design or copied by U disc trough PC design software, to realize its running and stop.

5.When the tuck in mechanical device running, it is synchronized with the loom main shaft.

6.Installing a revolving encoder,Tuck in mechanical device synchronized running with the loom main shaft trough cabinet alignment adjustment combining device.

7.Cabinet alignment adjustment can adopt PDA operation type.

8.The tuck in mechanical device running synchronized with the loom main shaft allows the cabinet buffering control it stop or running on the premise that not effect the yarn to be turned in.

9. Buffering controlling can adjust the corresponding acceleration value can be made by the computer aided system to the mechanical mechanism.

10.The servo motor with a ring number memory function, can realize the current memory number of weft, weft and operation function

11.Weft advance or retreat can operated in the touch screen.

12.The servo control system has the anti-collision function, when the servo servo control system, can issue commands to folding machinery immediately recover to 0 degrees position, to avoid collision with reed.

13.The servo control system has the function of losing electricity protection, when a sudden power failure occurs, the folded edge device will follow the slow synchronization of the loom, and finally stop at the 0 degree of the loom.

14.The servo control system is provided with a flower type storage function, which can store a plurality of flower types, and can conveniently call the function of the servo control system.

15.The servo control system of automatic restart function of zero power loss, different models according to the method of setting a change.

The tucking-in device is the accessory fixture of looms.

It can be used on rapier loom, projectile shuttle looms and airjet looms. Because the shuttleless loom adopt machine weft supply, the weft bobbin locate the outside of cloth - fell static position. The weft is cut by the weft scissors, so a bit of yarn is outside of the fabric

The ZRB561 tucking-in device, installed with fully enclosed oil splash lubrication structure. Underneath type gear transmission. It can be top mounted to the left, right or middle loomfrontrest. Its speed can match to 200 rpm rapier loom. It can be used to make Cotton, hemp, wool, silk, chemical fiber, glass fiber, plastic material fabric with one or more width.

1. Tuck in Device For Rapier Loom

2. Left side + Right Side

3. High Postion Mouting

4. 8-12mm Selvedge Range

5. Suitalbe for 250 RPM Loom Speed.

Products Photos:

Application:

Fabric Working:

For Silk

For Silk

For Cotton Blanket

For Cotton Blanket

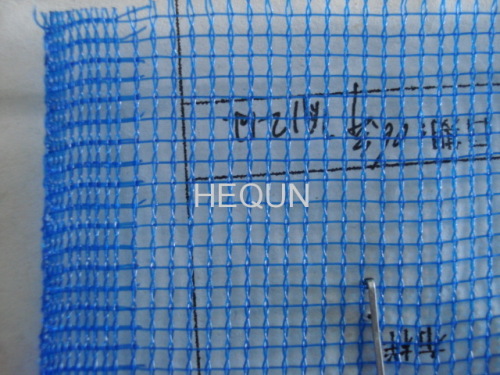

For Window Gauze

For Window Gauze

For Window Gauze(interview)

For Window Gauze(interview)

For Scraf

For Scraf

Making Scraf

Making Scraf

For Sunshade Net

For Sunshade Net

For Window Gauze

For Window Gauze

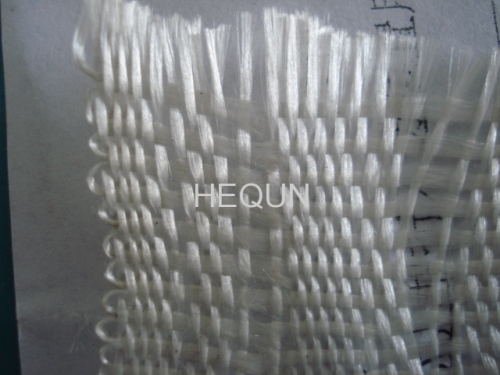

For Linen

For Linen

For

For

Glassfiber

Our Company:

Zhejiang Hequn Machinery Co., Ltd. was founded in 1985, covers an area of 86580 square meters, the number of employees reached more than 400, is a large-scale, professional textile machinery enterprises. And in early 1999 we has been ISO9000 certified which is the lead of the industry.

We uphold the people-centered, continuous innovation, sustainable development principles, and has developed a number of new products with independent intellectual property rights, enjoys high praise from customers. We continuously introduce new equipment in the international forefront in the technology and equipment modification, such as vertical machining center, CNC lathe and horizontal machining center, grinder, cam, and is equipped with three coordinates measuring instrument of the most advanced, cam curve measuring instrument, length measuring detector and other testing equipment.

We are producing series shedding devise by "Hequn" brand ,which enjoys a fast sale in major provinces and cities in the China, and the share in Southeast Asia market is continuously expanded, In Indonesia, India, South Africa, Bangladesh, Pakistan, Vietnam and other countries, our market share reached as high as 65%.

Hequn people have been adhering to the principle of "Quality First, Service First, Business Integrity", keeping production "exact & innovation" to serve our customer, and repay the society.

Our Customers:

Contact Us:

Zhejiang Hequn Machinery Co.,Ltd

ADD: Chengtan Town Industry Zone, Xinchang County, Zhejiang Province,China

Tel:0086-575-86054831 Fax: 0086-575-86058353

Jessie Zhang Sales Manager

Mobile Phone No: 008613905856439

Wechat Id: 008613905856439

Whatsaap Id: 008613905856439