sandal soles for making shoes factory machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20set/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | jg807 |

|---|---|

| Means of Transport: | Ocean |

| Condition: | New |

| Power Supply: | Electric |

| Function: | Shoemaking Line |

| Applicable Material: | Other |

| Tank quantity: | 5 |

| Tank capacity: | 250L |

| Place of Origin: | Zhejiang, China |

| Model Number: | JG |

| name: | pu shoe machinery |

| name1: | shoes injection machine |

| Characteristics: | Can produce two different material |

| Raw material: | PU |

| Motor: | from Japan |

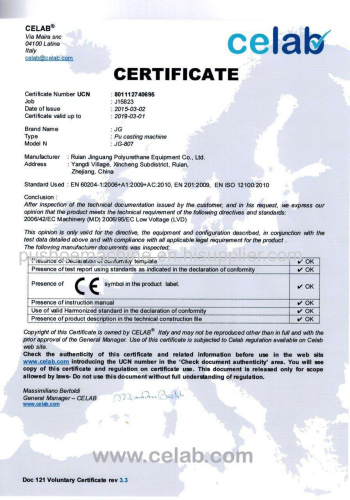

| certification: | CE |

| Production Capacity: | 20set/month |

| Packing: | wooden case shoe making machine |

| Delivery Date: | 25day |

Product Description

sandal soles for making shoes factory machine

Control system:

1, With the state of the art computer controlled system to gain the machinery more efficiency and reliability.

2, Self-diagnosis, alarming and monitoring functions and multi-language alternatives.

3, Preset technical parameters.

4, Reserve electrical interface for mechanical arm

5, PID closed-loop and self-regulated injection program

6, Automatic PID temperature control

7, Emergent halt protection device.

Specifications

With 5*250L material tank, single pouring head,

can make four color four density polyurethane shoe sole.

PU Shoe (Sole) Making Machine Characteristics:

1. Have four A tank and one B tank, can make different density and different color foaming outsole by mix each A and B under requirement.

2. Under different proportion of A and B raw material, can get different properties polyurethane sole material.The mix head with six needle which can work independently.

3. Heating system with oil circulation, make heating more fast and more efficient in power saving.

4. Self-developed PLC, with function of setting time, real-time monitoring and so on.

5. The speed of pump use frequency conversion control, with advantages of energy saving and keep the rotational speed when voltage instability.

6. The speed of mix head can reach 9000r/min, it can obtain the most homogeneous material.

Engineer will gone abord to follow up the aftersale and training for our new customers every year.

Technical Parameter:

| 1 | Model | JG-807 |

| 2 | Tank quantity | 5 |

| 3 | Tank capacity | 250L |

| 4 | Pump quantity | 4 |

| 5 | Speed of pump(r/min | 0---280 |

| 6 | Precision (%) | ±0.5 |

| 7 | Max rotating Speed of injection screw | 4500/8600-10000 (Choice by yourself) |

| 8 | Clean the head | Automatic/By hand |

| 9 | Voltage | 380V,50HZ |

| 10 | power | 20(kw) |

| 11 | Clean quantity | 4500(r/min)>25,9000(r/min)>160 |

| 12 | Product characteristics | four color four density Can produce two different material |

| 13 | Productivity(output ) | if work 8 hours can produce 3600pairs of the shoes. every four minute can produce 30prs of the shoe. |

.CE

The packing and shipping

The production workshop

Attend trade shows

Our Services

Company Information

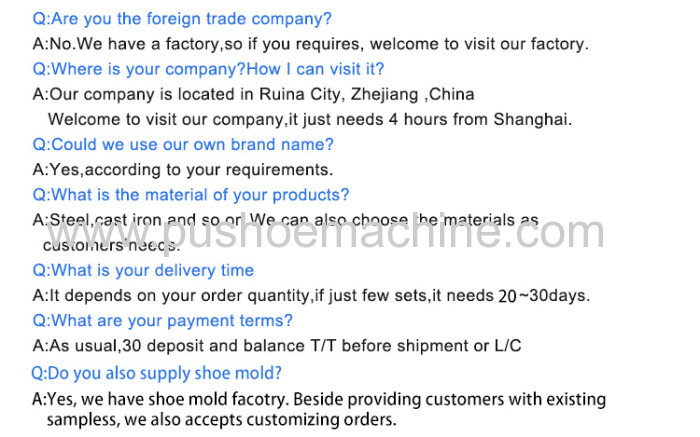

FAQ