RO membrane 100 GPD

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50K pcs |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | RO-100GPD |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Classification: | Water Purifier |

| Installation: | Portable |

| Type: | Ionizer (Water Purifier) |

| Certification: | CE |

| Production Capacity: | 50K pcs |

| Packing: | paper carton |

| Delivery Date: | 25 days |

Product Description

Wiht following features:

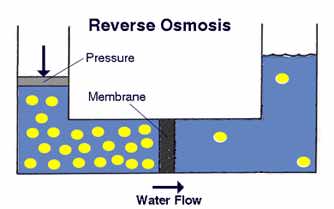

Reverse Osmosis Membrane This semi permeable

membrane filters and rejects tiny impurities down to 1/10, 000th of a micron

removing at least 95% of all impurities such as colloid, heavy metal, dissolved

solids, germs and other harmful substances. Virtually only water molecules and

dissolved oxygen can pass through the Reverse Osmosis Membrane. The rejected

contaminants are flushed to drain. The product water is the extremely pure,

crisp healthy drinking water.

Reverse Osmosis Membrane This semi permeable

membrane filters and rejects tiny impurities down to 1/10, 000th of a micron

removing at least 95% of all impurities such as colloid, heavy metal, dissolved

solids, germs and other harmful substances. Virtually only water molecules and

dissolved oxygen can pass through the Reverse Osmosis Membrane. The rejected

contaminants are flushed to drain. The product water is the extremely pure,

crisp healthy drinking water.

Product | A | B | C | D |

RO-1812-50 | 21±0.5mm | 255±2mm | 44.0±1mm | 17±0.1mm |

RO-1812-75 | 21±0.5mm | 255±2mm | 46.5±1mm | 17±0.1mm |

RO-2012-100 | 21±0.5mm | 255±2mm | 48.0±1mm | 17±0.1mm |

Product | Applied Pressure psig | Permeate Flow Rate GPD | Stabilized Salt Rejection Cl_% |

RO-1812-50 | 60 | 50 | 97.5 |

RO-1812-75 | 60 | 75 | 97.5 |

RO-2012-100 | 60 | 100 | 96 |

1. Permeate flow rate and salt rejection based on the following conditions: 250 ppm softened tapwater, 77°F (25°C), 60 psig (3.4 bar) and 15% recovery.

2. Permeate flows for individual elements may vary +/-15%.

3. Minimum Salt Rejection is 97%.

4. Product specifications may vary slightly as improvements are implemented.

• The first full tank of permeate must be discarded. Do not use this initial permeate for drinking water or food preparation.

• Rotate the element about a quarter turn to ease installation and removal of the element. Ensure good interface between the o-rings and brine seal with their connection surfaces.

• To ease installation, it is recommended to use a lubricant safe for indirect water contact on all seals. Potential options include water, glycerin based lubricants.

• Keep elements moist at all times after initial wetting.

• The membrane shows some resistance to short-term attack by chlorine (hypochlorite). Continuous exposure, however, may damage the membrane and should be avoided.

MEMBRANE REJECTION RATE

| Material/Element | % Removed | Material/Element | % Removed |

| Barium | 97% | Potassium | 92% |

| Bicarbonate | 94% | Radium | 97% |

| Cadmium | 97% | Selenium | 97% |

| Calcium | 97% | Silicate | 96% |

| Chromate | 92% | Silver | 85% |

| Copper | 97% | Sodium | 92% |

| Detergents | 97% | Strontium | 97% |

| Fluoride | 90% | Sulfate | 97% |

| Lead | 97% | PCBs | 97% |

| Magnesium | 97% | Insecticides | 97% |

| Nickel | 97% | Herbicides | 97% |

| Total Dissol Solids | 95% | ||