PP Melt Blown Filter Cartridge Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets per month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | WXHT01 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | WXHT |

| filter cartridge making machine: | extruder |

| pp melt blown filter cartridge machine: | pp spun bond filter cartridge machine |

| Production Capacity: | 10 sets per month |

| Packing: | Packing:Plywood case |

| Delivery Date: | 25 days after deposit |

Product Description

Product Description

The whole set include 11 parts as below:

| Item | Quantity |

| Screw-air compressor | 1 |

| Air tank | 1 |

| Air heating machine | 1 |

| Automatic feeding machine | 1 |

| Extruder | 2&3 |

| Mould | 2&3 |

| Receiving machine | 1 |

| Automatic cutting machine | 1 |

| Big controller | 1 |

| Small controller | 1 |

| Molds cleaning oven | 1 |

Parameters of pp melt blown filter cartridge machine

The rated power: 54.7KW (whole production line)

The actual power: 27kw-32kw

Production capacity:3200-3800pcs/day

Filter precision:1micron,3mciron,5micron,10micron...

The raw material :100%polypropylene

Speed of machine:0-1400r/min(adjustable)

Inner diameter:Default 28mm (other size could satify according to customers requirment)

Outside diameter:38mm-120mm (if the inner diameter is 28mm)

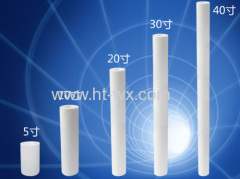

Length:5'', 10'', 20'', 30'', 40''.............100''

Filter Precision:1-100

Operation conditions:

1)Max operating temperature: 70°C

2) Materials: 100% polypropylene

3)Interface of filter cartridge: flat,dotted,grooved,carved,etc

4) Max differential pressure: Positive 0.4Mpa

Filter precision (μ m) | 1 | 3 | 5 | 10 | 20 | 30 | 50 |

Initial precision (μ m) | 10-15 | 15-25 | 25-35 | 30-40 | 35-50 | 40-60 | 60-90 |

Max particle (μ m) | 15 | 25 | 35 | 40 | 50 | 60 | 90 |

Flow (L/min) | 10 | 14 | 17 | 20 | 24 | 28 | 32 |

Parts Detailed Pictures for your referrence:

1.Adopts best quality electric appliance:ABB inverter,Omron ammeter,Schneider MCCB.

2.Adopt high quality and high price air compressor and air tank to supply air

3.Adopt stainless steel material for the whole set machine

4.Supply additional machines shirnk film packing machine,grooving machine and carving machine

Accessories

FREE PARTS

Heating loop inside of extruder:8pcs | Sensors: 5sets |

Heating pipe inside of air heating machine:3pcs | Bearing: 2pcs |

Temperature controller: 3 pcs | Tool box:1 set |

Button:2 pcs for 3 kinds. | Blade: 20pcs |

porcelain bead and line: some | Heating gun:1 set |

Water-oil separator for screw compressor:1 set | Machine oil filter for screw compressor : 1set |

Air filter for screw compressor: 1set | |

Advantages

| Large output | 3200-4000PCS |

| Low power consumption | Our machine is improved,Now the rated power is 54.7kw,and actual power is 27kw-32kw |

| Best quality | Our machines adopts best parts into machine,such as ABB,Omron... Now our machine passed CE and ISO9001:2008 certificate. |

| Operation | Our engineer will teach you how to operate machine in our factory when you come to our factory. |

| After sales service | We provide one year after sale service.and long time maintenance.In one year,we will provide new parts if yours is broken without human factor. |

Packaging & Shipping

1.We have exported to Italy,Germany,France,Mexico,Brazil,Argentina,Columbia,India,Vietnam...

2.All machines are packed by plywood case,after machine tested more than 3 times by our engineer

3.We supply lots of spare parts and tool box for each machine