High Performance Magnetic Shaft Coupling Reactor Coupling

Company Profile

| Location: | Xiamen, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Magnets, Neodymium Magnets, Magnetic Assembly, Magnetic Separators, Ma |

Product Description

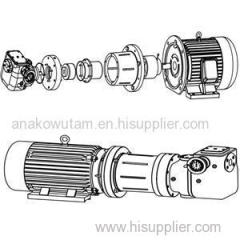

Among those famous reactor coupling manufacturers, it is a professional supplier in China, welcome to wholesale stirrer coupling, magnetic coupling in chemical reactor, chemical reactor coupling, magnetic coupling for pump, coupling for stirrer from our factory.Introduction of Magnet CouplingA permanent magnetic coupling transfers torque from one shaft, but using magnetic force rather than a physical mechanical connection. Major parts of a coupling are follower and driver. The driver is connected to a motor, when follower reacts to the driver's motion, this results in the transmission of mechanical energy without contact.GME coupling can transmit torque from 0.15 to 1000 Nm between two shafts through magnetic forces without mechanical contact. The couplings are often used to eliminate any possible fluid leakage from the pump forever and without maintenance. They can be designed to suit different machinery without altering system. Features of Magnet Coupling· Long life and low maintenance costs· Very high efficiency and hermetically sealed· No contact of torque transmitting elements with permanent magnets· Hermetic separation of the driving and driven side· Torque from 0.15 to 1,000 Nm and torque Overload protection· Eliminates the need for dynamic shaft seals· Tolerate shaft misalignments· Sliding bearing optional· Frequently used in vacuum and fluid pumpsAdvantages of Magnet Coupling· Elimination of fluid leakage from the pump shaft.· Vibrations are not transmitted to the pump.· Increased safety and energy savings and no maintenance required for coupling.· Standard pumps without expensive mechanical seals are allowed to use.· No additional cost for purchasing mechanical seal spare parts and maintenance.· Couplings can be customized to suit different machinery.Construction of Magnet CouplingNo.DescriptionMaterial1Separator looking ringaluminum 60822Bell housingaluminum 60823Containment shroud ( separator )AISI 304 or TECHNOPOLYMER4Electric motor side flangealuminum 60825Pump side flangealuminum 60826O ringViton or PTFE7O ringViton or PTFE8Electric motor hubaluminum 60829pump hubaluminum 608210Internal rotorFe52011External rotorFe520Design Considerations of Magnet Coupling1) Operational environment of coupling2) Coupling target gap3) Annual usage demand of coupling4) Coupling rotational/linear speed(RPM)5) Required mechanical features, such as mounting hole, shroud, shaft size etc.6) Fluid viscosityMagnet Coupling Selection--Technical data of specifying correct couplingFluid/GasFluid viscosity (cSt)Fluid temperature (°C)Ambient Min. Temp. (°C)Driver shaft (usually motor side)Input rating (kW)Number of polesNominal operational speed (RPM)Torque of motor (Nm)Type of motor start (direct/soft/by inverter)Driven shaft (usually pump side)Type of pumpDimension of PumpPump installation position (vertical/horizontal)Pump suction pressure (Bar)Max. pressure inlet port pump (Bar)Max. pressure outlet port pump (Bar)Max. displacement at max. pressure and min. variable stroke (cm³/rev)Dimensions of Magnet CouplingGDSA SeriesGDSB SeriesGDSM SeriesGDH SeriesDetection Equipment for Magnetic CouplingApplication of Magnet CouplingDue to its advantages, GME magnetic coupling is widely used in various fields, such as Biotechnology, Petrochemistry, Subsea Equipment, Pharmaceutical Industry, Chemical Industry, food Industry, Electrical Generators, water management etc.